The Importance of Supply Chain Management for Process Manufacturers

Supply chain management in manufacturing industry is the strategic planning and coordination of all activities involved in sourcing, procurement, production, and the movement of goods from the supplier to the manufacturer to the wholesaler to the retailer and, to the end consumer. SCM encompasses all the processes and activities required to design, plan, execute, monitor, and optimize the supply chain to ensure the efficient flow of products, information, and finances.

The goal of process manufacturing supply chain management is to create a streamlined, cost-effective, and responsive supply chain that meets customer demands while minimizing waste and inefficiencies. Industry specific and advanced software functionality can help process manufacturers reduce operating costs and improve customer service levels while being able to quickly react to changes in supply, demand, and transportation conditions.

KEY SUPPLY CHAIN MANAGEMENT PROCESSES

The supply chain is managed by a network of several connected and synchronized businesses that procure, produce, sell, and transport goods.

Each business or node in one’s supply chain employs various technologies to perform these key processes:

Planning

This involves setting objectives and creating strategies to meet customer demands while minimizing costs. It includes demand forecasting, network design, and inventory management.

Sourcing

Identifying and selecting suppliers, negotiating contracts, and establishing relationships with suppliers to ensure the availability of necessary materials and resources.

Procurement

The process of acquiring goods and services from suppliers, including order placement, receipt of goods, and invoice reconciliation.

Production

Managing manufacturing processes to ensure products are produced efficiently and in line with demand.

Logistics

This includes transportation, warehousing, and distribution. It focuses on the movement of products from suppliers to manufacturing facilities, between manufacturing facilities, and to distribution centers and retailers.

Inventory Management

Optimizing inventory levels to balance the cost of holding inventory with the cost of stockouts or overstocking.

Production

Predicting future customer demand to plan production, procurement, and distribution accordingly.

Customer Service and Order Fulfilment

Ensuring timely and accurate delivery of products to customers and addressing customer service inquiries or issues.

UNIQUE SUPPLY CHAIN CHALLENGES FACED BY PROCESS MANUFACTURERS

Companies in the food, chemical, nutraceutical, and life sciences industries will need to run a variety of software applications that can effectively manage industry-specific processes, due to inherent nature of the products and the agencies that regulate these industries.

Perishable and volatile products, expiration dates and shelf lives, and potencies and strengths, all poise a challenge in sourcing and planning of raw materials, then the production of shipping of finished goods for every business or node in the supply chain.

Strict regulatory labelling, identification and documentation of all raw material and finished goods by every business or node in the supply chain must be adhered to.

Tracking and tracing raw materials and finished goods as they move from one facility to the next in one’s supply chain is required to meet industry regulatory requirements.

KEY SUPPLY CHAIN RELATED ACTIVITIES WITHIN THE PLANT

An efficient supply chain management software provides comprehensive inventory management capabilities effectively manage product variability, identification, and track & trace requirements across all warehousing and production-related activities performed in a production plant, which is one of the nodes within one’s supply chain.

Planning & Scheduling

ERP software considers various supply & demand factors along the supply chain, such as vendor delivery dates and customer shipment dates, to optimize production and procurement. As a result, just in time plant operations with faster inventory turns can positively impact one’s supply chain operations.

Warehousing – Inbound

PO receiving of raw materials is fast and accurate, allowing inventory to be tagged and tracked from receiving into production. On the spot receiving with mobile devices improve user productivity and updates inventory immediately, allowing production jobs to be planned and released asap.

Production

Organizations need to handle ingredients and raw material availability, shelf-life management, SKU tracking, seasonal demand variations, and more. With process manufacturing software, accurate scheduling and forecasting can be improved, as well as inventory availability, workload, and supply chain logistics. Process manufacturing software gives you real-time data insights to accurately coordinate/order ingredients depending on actual customer demand, along with managing supplier needs efficiently.

Warehousing – Outbound

Sales order fulfilment processing of finished goods is fast and accurate. Mobile picking and shipping improve user productivity and inventory turns, as well as updates inventory immediately, allowing customers to be invoiced quickly.

BATCHMASTER BENEFITS FOR SUPPLY CHAIN MANAGEMENT

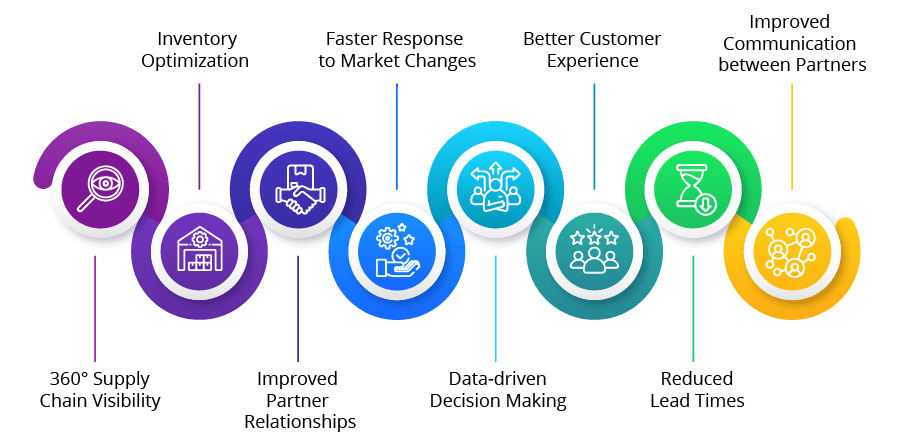

BatchMaster supply chain management software plays a important role in enhancing the efficiency and effectiveness of supply chain operations in multiple ways. It provides real-time visibility into plant operations, aiding in informed decision-making and quick responses to changes. Through data-driven insights, it optimizes inventory levels, balancing availability with cost reduction. Additionally, it reduces lead times, streamlines communication with partners, offers mobile access, and supports better coordination, ultimately optimizing the entire supply chain.