Master Production Scheduling (MPS) Software

OUR MASTER PRODUCTION SCHEDULING SOFTWARE ENSURES YOU CAN MEET YOUR CUSTOMER COMMITMENTS

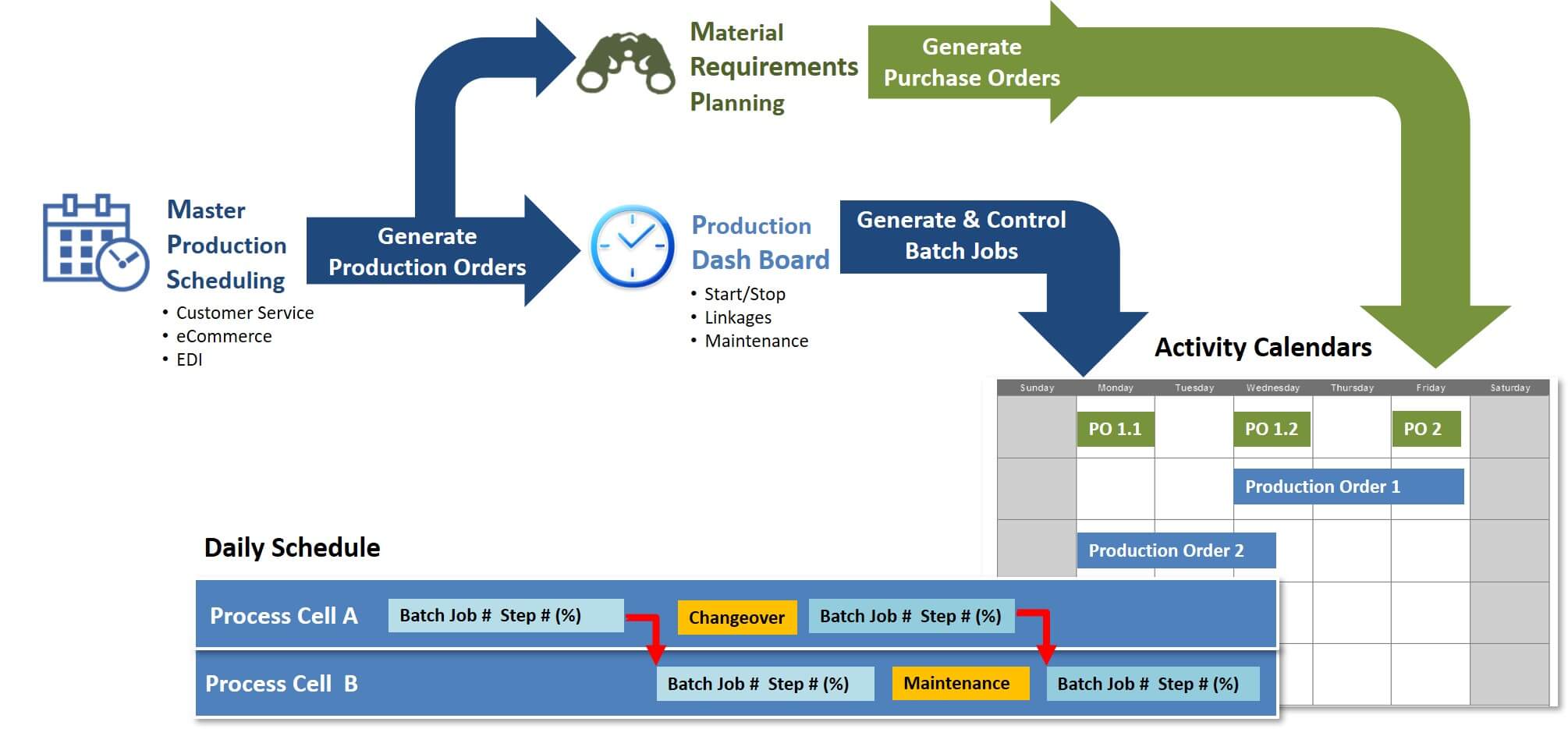

Production schedule software, commonly known as Master Production Scheduling (MPS) in ERP, provides a master plan for what you need to produce, how much and when to produce it. Your open production orders, sales orders and forecast entries are used as finished goods demand, and your inventory levels, batch production jobs, and receipts are considered as supply. MPS generates an accurate, detailed schedule of orders across one or more plants, based upon this granular view of supply and demand.

Schedulers have a calendar view of planned orders with drill down, analysis, grouping and rescheduling capabilities. Using the scheduling dashboard, one can evaluate the batch jobs created in a master production schedule by their groupings (e.g. allergen, item, or priority) and review the relationships between their supply and demand factors.

MASTER PRODUCTION SCHEDULE SOFTWARE THAT

WILL CHANGE THE WAY YOU WORK

Our ERP production scheduling software creates the optimal number of batch jobs required to meet current and forecasted demand, so that you can meet your customer service promises, in terms of perfect orders and delivery dates.

- Establish short, medium and long range planning periods

- Perform “what-if analysis” while planning production

- View time-phased aspects of required production, based on forecast and demand

- Auto conversion of MPS orders to purchase orders and batch production jobs

- Consolidate supply and demand of facilities

- Schedule MPS processing on a frequency or calendar basis

- Perform demand to supply pegging as well as supply to demand pegging

NEED AN ADVANCED PRODUCTION SCHEDULING TOOL?

Take advantage of a finite capacity scheduling tool that creates and adjusts production schedules in minutes and considers:

- Available labor force, including their calendars and their skill sets.

- The cost to produce an item on a piece of equipment.

- Inventory shortages at the time of batch job production.

- Incremental batch job tasks, including equipment setups.

- Machine availability, sequencing rules and other secondary constraints.

MATERIAL REQUIREMENTS PLANNING

Material Requirements Planning (MRP) optimizes your procurement of raw materials, allowing you to maintain optimum inventory levels while minimizing carrying costs. MRP gives planners a detailed, consolidated view of supply and demand.

CONTACT US / REQUEST A DEMO

Let’s see if BatchMaster Software has the right software solution for your needs. Contact Us to share something about your operations and software needs with our consultants or Request A Demo of one of our software applications.