Sage 100 & 300 Integration to BatchMaster Manufacturing

Introduction To BatchMaster Manufacturing Solutions

FORMULA-BASED, PROCESS MANUFACTURING FOR SAGE 100/300

BatchMaster is a leading Sage 100/300 manufacturing software application that effectively manages all the process manufacturing complexities inherent in the food, chemical, nutraceutical and life sciences industries.

Process manufacturers running Sage 100 & 300 can all take advantage of our BatchMaster Manufacturing application, which can be quickly deployed either on-premise or in the cloud.

CHALLENGES RUNNING SAGE 100/300

Process manufacturers typically find that Sage 100/300 hampers their ability to scale up and streamline their manufacturing operations as well as meet specific operational requirements, such as delivery commitments, unique product requirements and regulatory compliance.

Some of these process manufacturers found that using paper, spreadsheets and even inventory management / stock locator software apps in conjunction with Sage 100/300 was still not enough to meet their operational objectives.

Many of these process manufacturers are being told by ERP software vendors that they should replace Sage 100/300 with their ERP solution.

Before you replace Sage 100/300, consider the add-on process manufacturing app from BatchMaster Software!

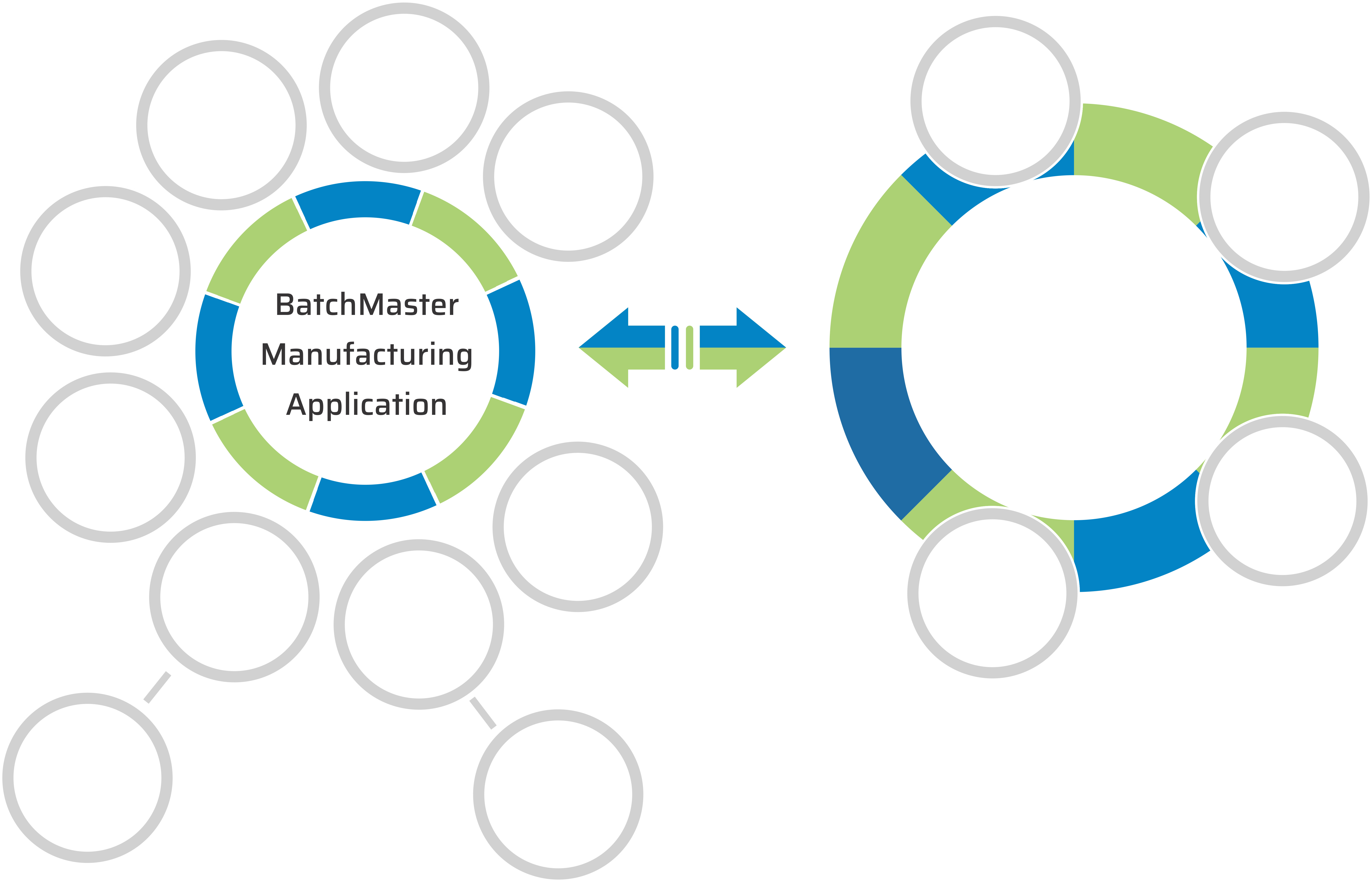

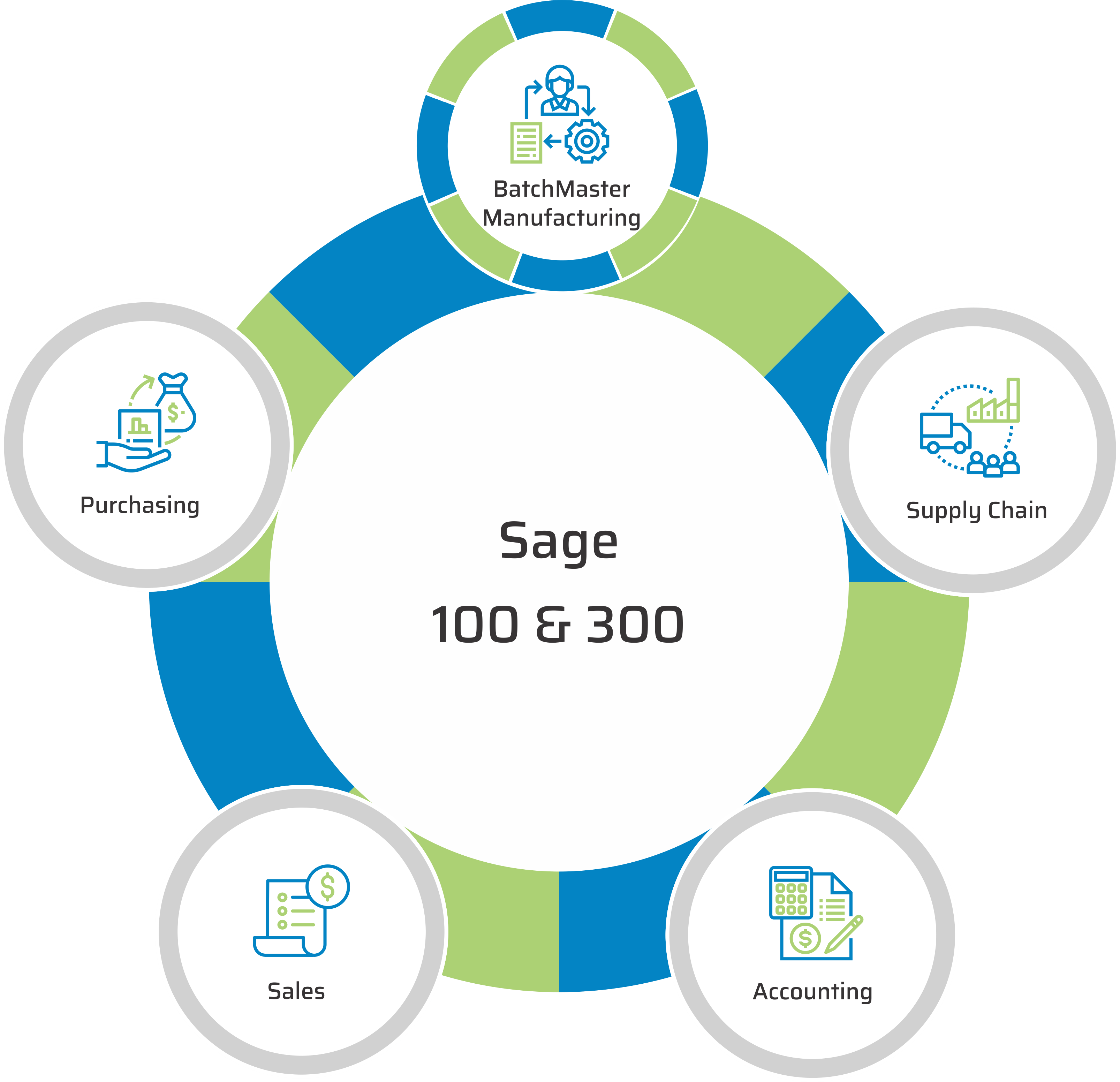

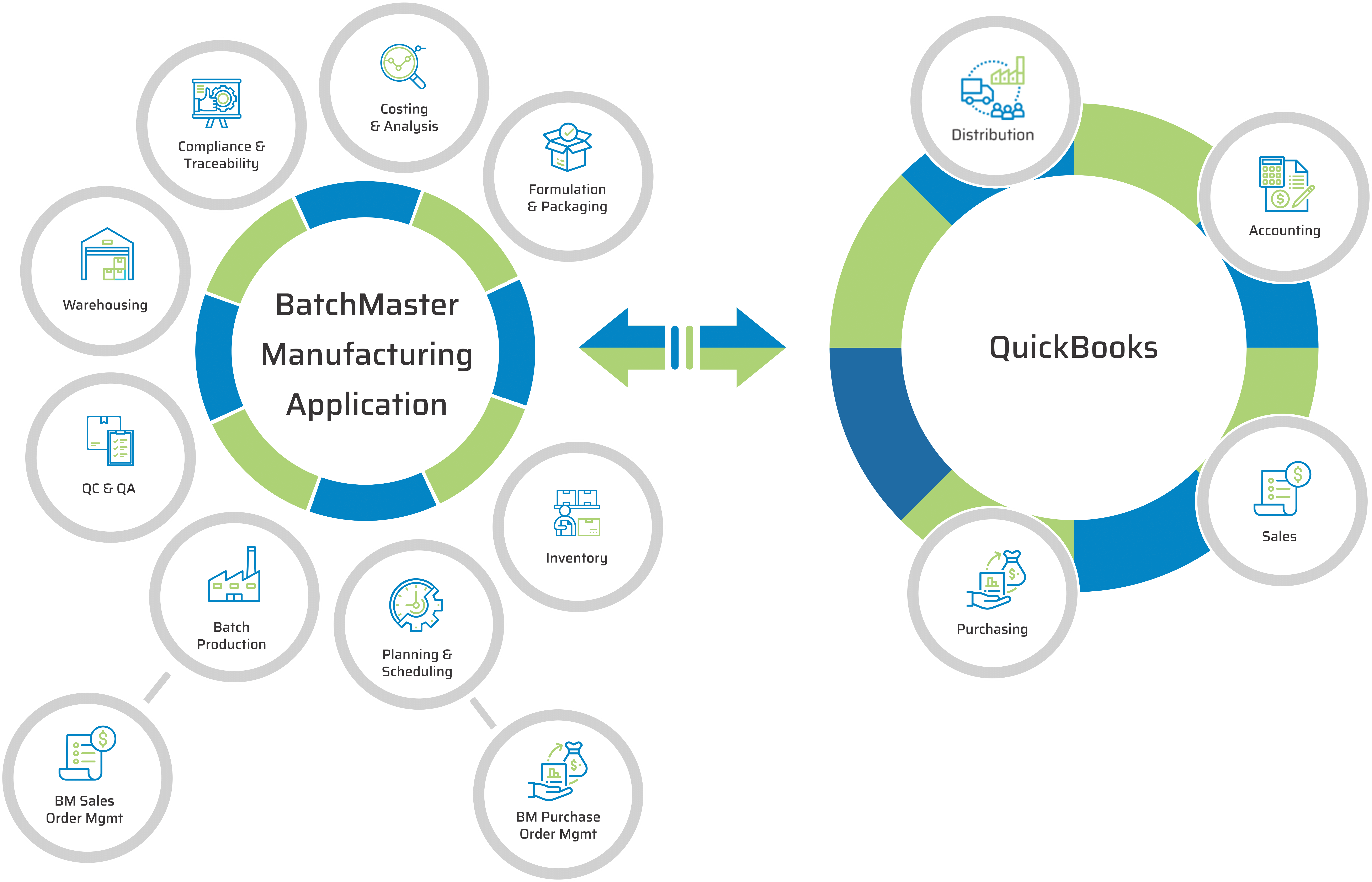

SAGE 100/300 AND BATCHMASTER - A BEST OF BREED SOFTWARE SOLUTION

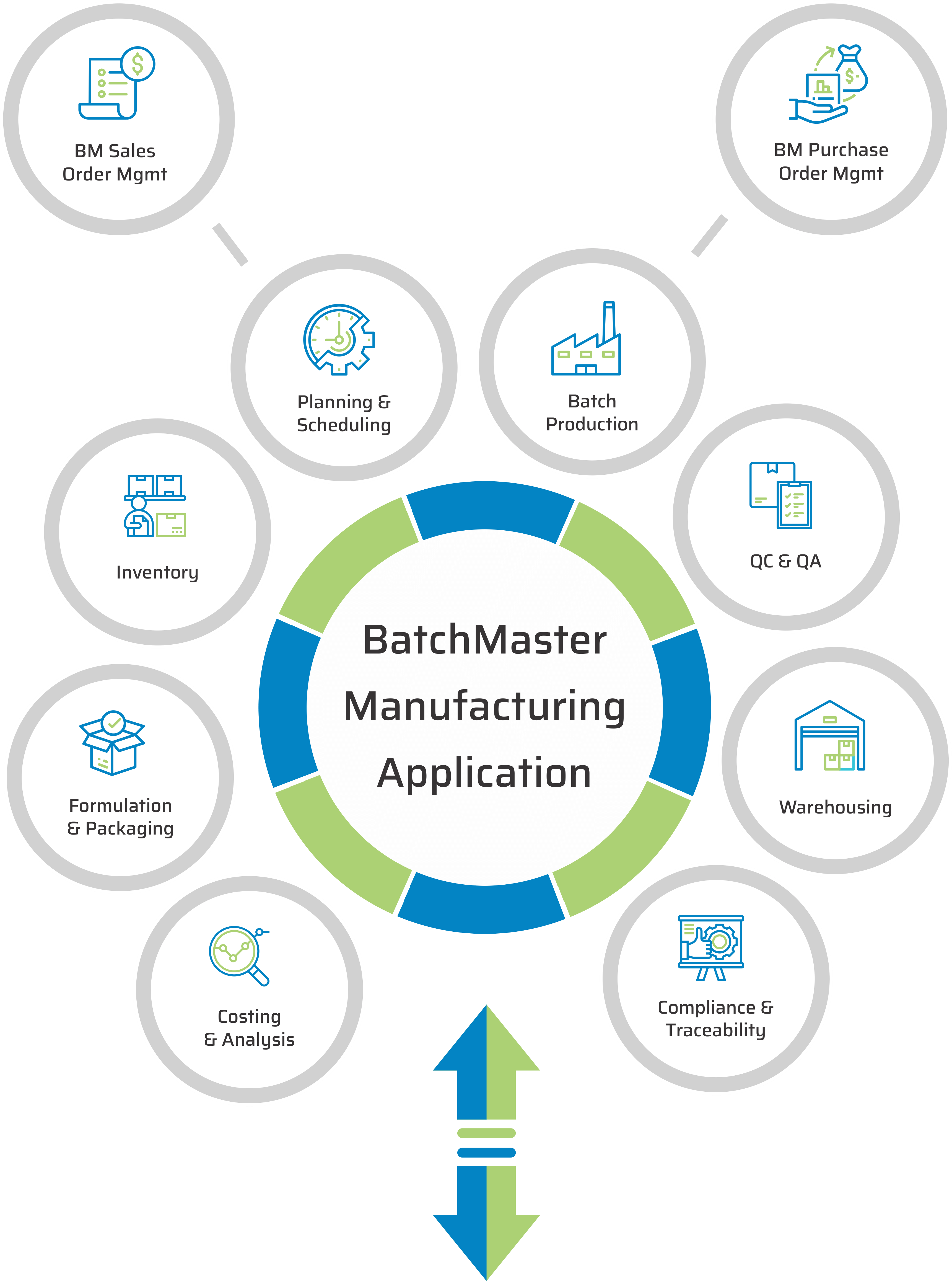

The BatchMaster manufacturing application manages Inventory, Sample Management, Lab, Formulation, Production, Costing, Quality, Compliance, Planning, Scheduling and Warehousing. In addition, Sales Orders, and Purchasing are put under BatchMaster’s control because our Planning and Scheduling modules require access to critical, granular manufacturing, customer, sales, and purchase order data in order to generate detailed plans on what needs to be made and when it needs to be made, as well as generate the right purchase orders for the materials required to execute that plan at the right time.

CONTACT US / REQUEST A DEMO

Let’s see if BatchMaster Software has the right software solution for your needs. Contact Us to share something about your operations and software needs with our consultants or Request A Demo of one of our software applications.

REFERRAL PARTNERSHIP PROGRAM

If you provide accounting, administrative or other services to formula-based, process manufacturers who run Sage 100/300, you may encounter clients who are struggling to control and streamline their manufacturing operations. As a BatchMaster referral partner, you get the insights you need to identify these opportunities and the materials you need to share with these clients. Contact us to learn how you can earn a referral fee for your recommendation of our software solution.

VIDEO

BatchMaster Manufacturing For Sage 100&300

Discover the essential features in product development, production, quality, costing, compliance, planning and scheduling.

WHAT OUR CUSTOMERS SAY

At the end of our ERP evaluation, we decided to partner with a technology company that offered us an off the shelf product that is formula centric, could easily meet our unique requirements, and give us the best ROI with minimal risk.

Cardinal Paints

BatchMaster Manufacturing for Sage tracks all QC detail from inventory receipt through finished goods production. And when the FDA conducts an audit, BatchMaster lets us demonstrate all the details of inventory and production QC history.

Westwood Laboratories

The next audit should be a breeze because of the documentation that BatchMaster Manufacturing produces. The solution has streamlined processes throughout our business.

Premier Research Labs

Previous

Next