Lot Traceability & Recall Software

EXCEED INDUSTRY REGULATORY TRACEABILITY & RECALL CODES

Food, chemical, nutraceutical and pharmaceutical manufacturers alike, all need some level of lot traceability capabilities in order to quickly respond to product defects and hazards to avoid customer chargebacks and industry fines, as well as support one’s epedigree and continuous improvement processes.

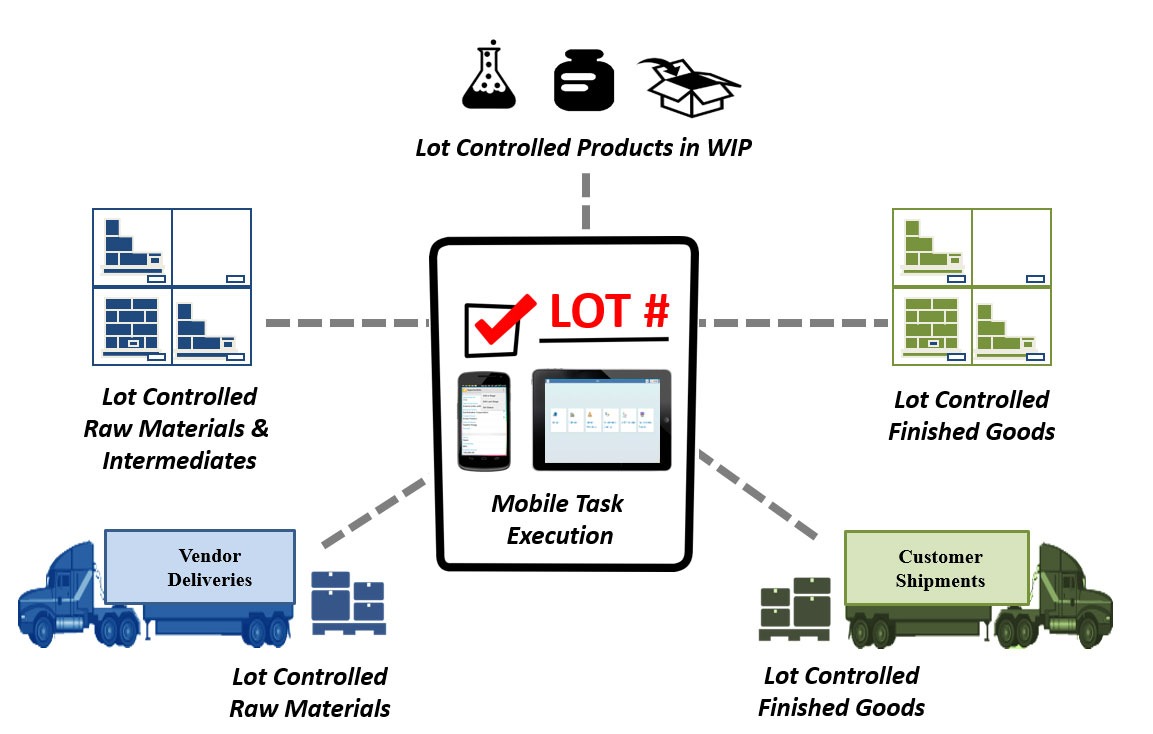

COMPREHENSIVE LOT MANAGEMENT FUNCTIONALITY

BatchMaster’s lot management capabilities address the mandated capture of and auto generation of lot numbers throughout the product lifecycle in the manufacturing plant, including:

- Capture vendor lot numbers at the time of receiving, and auto generate internal lot numbers associated to the vendor numbers

- Capture and validate lot numbers of inventory being putaway into inventory

- Allocate inventory by lot number for batch production jobs

- Capture and validate lot numbers of inventory being issued into production

- Auto generate lot numbers for finished goods produced, including co-products and by-products

- Capture and validate lot numbers of inventory being moved with in the plant, as well as being checked or adjusted (e.g. cycle count or physical inventory tasks)

- Allocate inventory by lot number for order fulfilment

- Capture and validate lot numbers of inventory being picked for customer shipments

Lot inheritance functionality maintains the lineage of all raw materials and finished products, including co-products and by-products. A sidebar on lot managed inventory, ingredients present in minuscule amounts in a finished good must be tracked and traced, so inventory quantity values are measured in the decimals in our manufacturing software.

TRACE PRODUCTS IN MINUTES

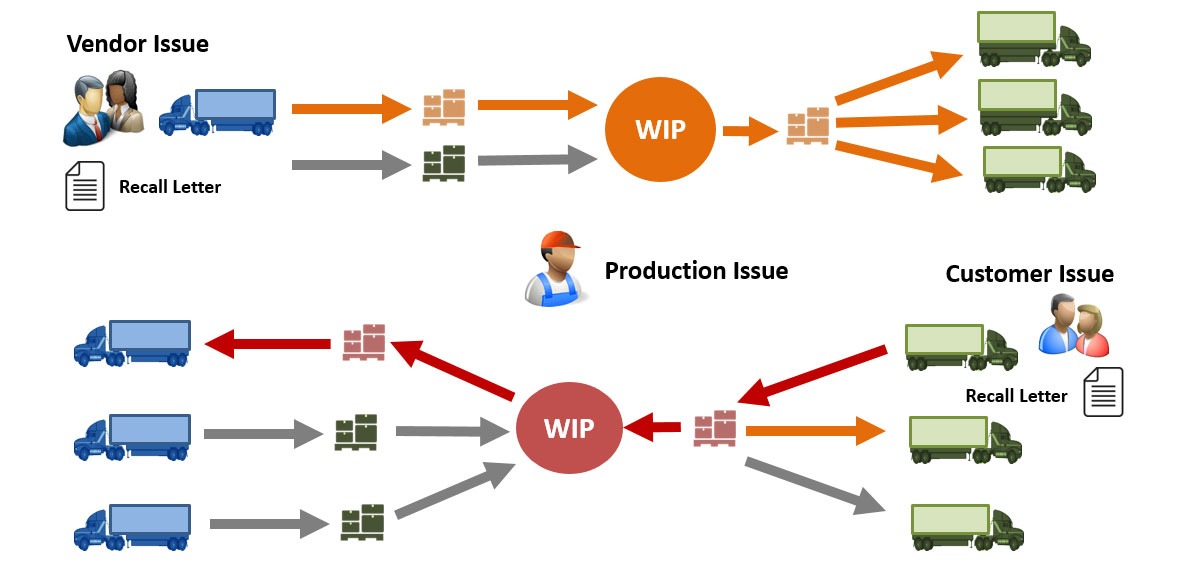

Speed and scope are key factors in searching for a suspect products, especially when responding to an adverse event, such as a heath related issue, or to a retailer’s mock recall program. BatchMaster’s lot traceability software can help food manufacturers exceed product traceability and recall code requirements stipulated in BRC / SQF advanced food safety certification programs.

A graphical lot traceability tool executes “bi-directional” searches to pinpoint on hold inventory, vendor deliveries and customer shipments. Suspect products can be quickly traced from a delivery to customer shipments, a customer shipment to deliveries and anywhere within the plant operations in minutes, not hours or days. In addition, the lot traceability tool can generate recall letters for suppliers and customers.

BatchMaster Software’s manufacturing applications for food, chemical, nutraceutical and pharmaceutical manufacturers will enable your company to speed product traceability and recalls, and stop the unnecessary practice of putting all lots of a product’s inventory on hold.

CONTACT US / REQUEST A DEMO

Let’s see if BatchMaster Software has the right software solution for your needs. Contact Us to share something about your operations and software needs with our consultants or Request A Demo of one of our software applications.