Paints & Coatings Manufacturing ERP Software

Explore BatchMaster Manufacturing

software for chemicals, paints, coatings, personal care, cosmetics

PAINTS & COATINGS ERP SOFTWARE HELPS YOU BRING US PRODUCTS TO PROTECT AND BEAUTIFY OUR SURROUNDINGS

BatchMaster Software offers paints and coatings manufacturing solutions that will help your company streamline operations and bring your products to market, faster and more cost efficiently, while complying with ever more stringent GHS regulatory mandates.

Whether you private-label, co-pack or produce your own line of residential, commercial or industrial paints and coatings, our paints and coatings manufacturing software supports your unique requirements in the areas of product development, production, inventory, quality, costing, lot traceability, SDS compliance, planning, scheduling, and warehousing.

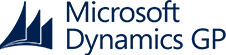

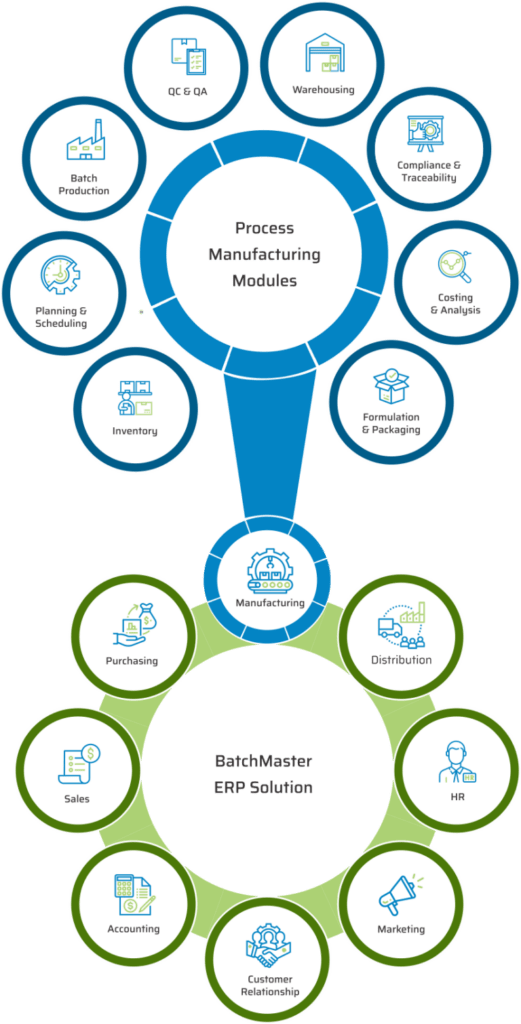

We can quickly and easily add our paints & coatings manufacturing application to your existing financials, including QuickBooks, Sage 100 and 300, Microsoft Dynamics GP and SAP Business One. Or if you are looking to upgrade your current manufacturing and financial business applications, we offer an end to end ERP for Paints & Coatings solution that gives you the adaptability, accountability, reliability, scalability and traceability functionality you need to rapidly and profitably grow your business.

BatchMaster software applications are available on-premise and in the cloud.

TOP CHALLENGES THAT CAN BE OVERCOME USING BATCHMASTER CHEMICAL SOLUTIONS

Raw Material Sourcing

The quality and consistency of raw materials, such as resins, pigments, and solvents, used in the production of paints and coatings can vary widely, making it difficult to maintain consistent quality in the final product.

- Employ BatchMaster to perform vendor inspections against delivered chemical ingredients that will be used in batch jobs.

Formulation Variability

Paint and coating formulations can be complex, and small changes in the amounts of ingredients used can have a significant impact on the final product. This makes it difficult to consistently produce high-quality products.

- Take advantage of BatchMaster’s multi-level formula specifications with flexible item UOM structures, automatic UOM conversions, and product quantities in the 6 decimal ranges.

Product Consistency

Achieving consistent characteristics, such as color, can be a challenge due to variations in raw materials (e.g. strengths, concentrations) and manufacturing processes.

- The variability of lot controlled raw material inventory is considered and adjusted for in BatchMaster’s batch job routines.

Regulatory Compliance

The production of paints and coatings can generate significant amounts of waste, including volatile organic compounds (VOCs) that contribute to air pollution. Manufacturers must take steps to minimize waste and reduce their environmental impact.

- Employ BatchMaster’s substation and physical property analysis tools to determine the optimal blend of chemical additives to meet target values. Also, track by-products or waste produced in batch production jobs in evaluating one’s current processes.

- Allocate the right inventory in batch jobs by considering the expiration dates and rotation methods of lot controlled raw materials

Environmental Concerns

The production of paints and coatings can generate significant amounts of waste, including volatile organic compounds (VOCs) that contribute to air pollution. Manufacturers must take steps to minimize waste and reduce their environmental impact.

- Employ BatchMaster’s substation and physical property analysis tools to determine the optimal blend of chemical additives to meet target values. Also, track by-products or waste produced in batch production jobs in evaluating one’s current processes.

Regulatory compliance:

Chemical manufacturers must comply with a range of domestic and international regulations (e.g. GHS, REACH), related to product labeling, handling, transportation, and disposal, in addition to multi language and currency concerns.

- Document Management features and an integration of one of the leading SDS authoring solutions enable companies to generate the necessary documents and labels.

Quality Control

Consistently producing high-quality paints and coatings requires rigorous quality control measures, including testing for color, viscosity, and other physical and chemical properties. Paint and coating manufacturers must maintain strict quality control standards to ensure that their products meet customer requirements and comply with strict industry standards.

- Production Job QC tests and SOP’s against products, equipment and facilities, plus QA inspection plans, deviations, nonconformance and CAPA features, all contribute to ensuring a manufacturer’s high quality standards are maintained.

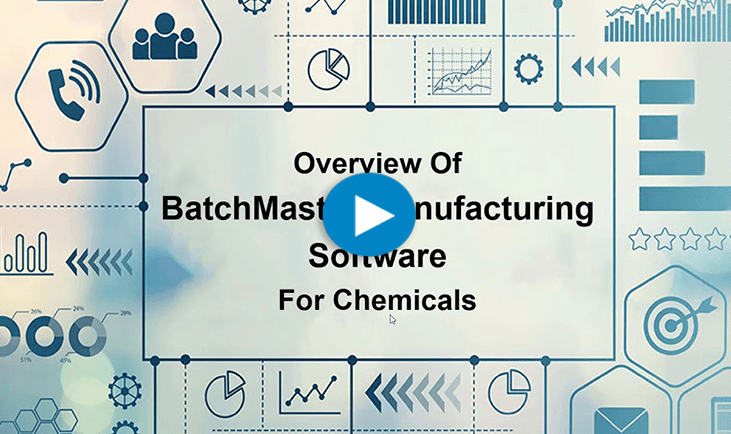

KEY MODULES FOUND IN OUR PAINTS & COATINGS MANUFACTURING APPLICATION

BatchMaster Software chemical manufacturing modules include recipe and packaging management, costing, inventory, production, quality, planning, scheduling, BRC/SQL traceability & recall, FDA compliance, and mobile warehousing. All of these chemical manufacturing modules are available in our add-on paints and coatings manufacturing application, which can be integrated to one’s existing financials, specifically QuickBooks, Sage 100 & 300, Microsoft Dynamics GP and SAP Business One. Our add-on paint and coating application is available on premise and in the cloud.

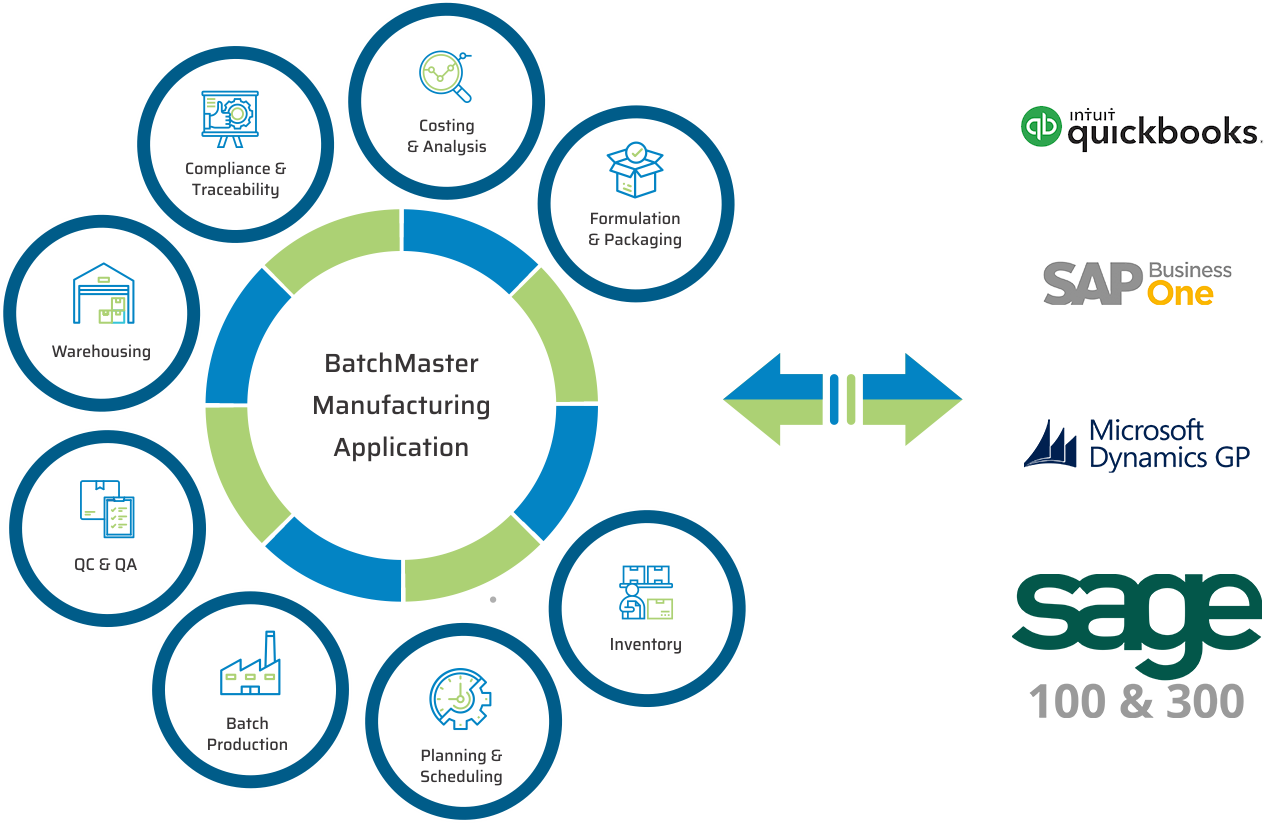

UPGRADE TO OUR ERP FOR PAINT & COATING SOLUTION

BatchMaster ERP is the enterprise resource planning system designed to meet all of your critical business needs within a single, cohesive platform

KEY MODULES FOUND IN OUR PAINTS & COATINGS ERP APPLICATION

KEY BENEFITS OF PAINTS & COATINGS MANUFACTURING ERP SOFTWARE

1. Accelerate Product Development

- Track progress of samples

- Allow multiple developers to work on separate formula and packaging specs

- Employ industry and user defined equations

- Dynamically adjust formulas to meet physical and cost target values

- Perform side by side comparison of specs

- Initiate multi-level approval workflows

- Generate SDS reports and labels

2. Quickly Scale Up Production

- Dynamically adjust specs and yields based upon available inventory

- Reserve inventory for customer orders

- Auto link and schedule batch jobs

- Manage equipment and resource availability and capacities

- Auto generate lot numbers for intermediates and finished goods

- Execute production related tasks via mobile devices

- Automatically backflush inventory

3. Ensure Quality

- Establish QC and QA inspection, checklist, and special instruction libraries

- Mandate task acknowledgements and quality data collection

- Auto disposition any sub standard inventory

- Generate customized COA reports

- Manage deviation and non conformance situations

4. Control Costs

- Define fixed, tiered and variable labor costs within specifications

- Identify costs of consumables

- Run what if cost analysis

- Dynamically adjust recipes to meet cost target values

- Consolidate demand using MRP and MPS for discount bulk purchases

- Optimize resources utilization based upon MRP and MPS planning

- Analyze expected vs actuals

5. Ensure Compliance

- Dynamically adjust recipes to meet label claims

- Generate FDA approved nutritional fact panels

- Generate bidirectional lot traceability reports

- Maintain full version control and audit history

- Auto assign lot numbers during receiving and production

- Track the variable characteristics of inventory

- View simultaneous dual units of measure

- Select the right inventory based upon expiry dates, certifications and status

- Reserve inventory for batch jobs

- Optimize inventory levels using automated planning and procurement

- Determine planning horizons and calendars

- Consider vendor delivery, order forecasts and planned production

- Prioritize customer orders

- Consolidate demand

- Link and schedule related batch order and runs

- Generate synchronized purchase orders

- Inbound receiving and putaway tasks

- Batch production functions and WIP inventory movements

- QC tests and special instruction tasks

- Outbound pick, pack and ship tasks

- Inventory adjustments, cycle counts and warehouse transfers

- Access real-time, accurate actionable data

- Employ drill down, role-based dashboards with graphical components

- Get quick data access using “favorite” shortcuts

- Customize industry inquiries and reports, as well as run ad-hoc queries

CONTACT US / REQUEST A DEMO

DOCUMENTS

Paints Brochure

A 6 page brochure addressing the challenges and requirements of chemical manufacturers, and the features and benefits of BatchMaster ERP for Paints & Coatings.

Functional Checklist

VIDEOS

Speed Product Development

Streamline Production

Comprehensive QC & QA

Discover the quality control & quality assurance software features that can ensure the continuous flow of high quality products as you scale up production.

Lot Traceability & Recall

See how our lot management capabilities enable you to expedite traceability and recall activities

WHAT OUR CUSTOMERS SAY