Food Manufacturing ERP Software

Overview of BatchMaster Manufacturing

Software for Food & Beverages

OUR ERP FOR THE FOOD INDUSTRY HELPS YOU BRING HEALTHY AND TASTY FOODS TO OUR TABLES

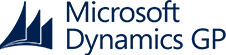

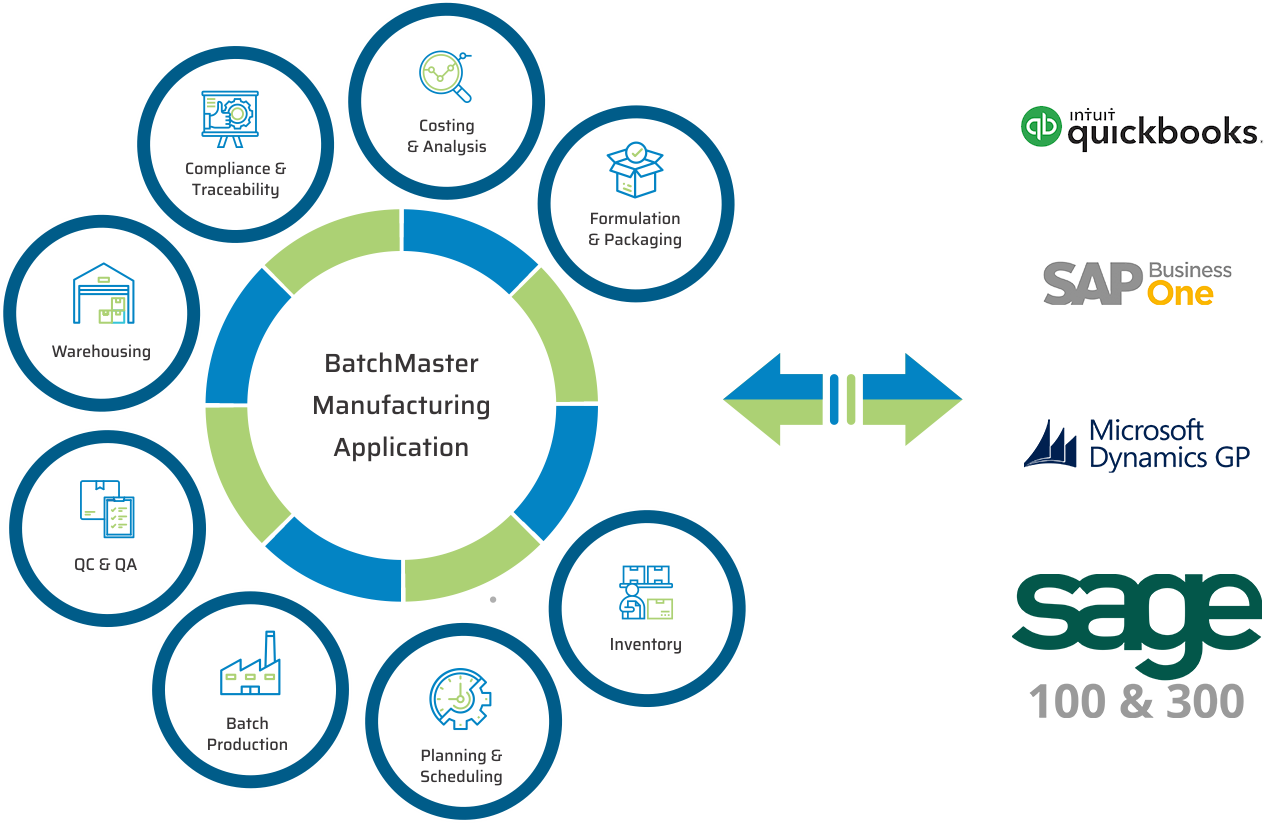

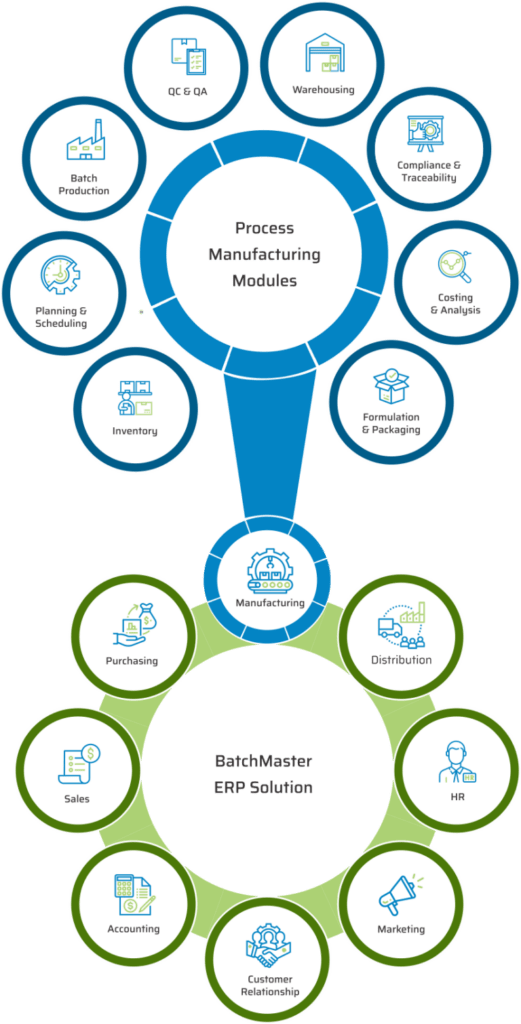

We can quickly and easily add our food manufacturing application to your existing financials, including QuickBooks, Sage 100 and 300, Microsoft Dynamics GP and SAP Business One. Or if you are looking to upgrade your current manufacturing and financial business applications, we offer an food manufacturing ERP solution that gives you the adaptability, accountability, reliability, scalability and traceability functionality you need to rapidly and profitably grow your business.

BatchMaster software applications are available on-premise and in the cloud.

GAIN VISIBILITY AND EFFICIENCIES WITH OUR FOOD ERP SOLUTIONS

TOP CHALLENGES THAT CAN BE OVERCOME USING BATCHMASTER FOOD ERP SOLUTIONS

Health Concerns:

As consumers demand more health-conscious choices, food manufacturers continue to develop more sugar-free, low-calorie, and low-fat options.

- Take advantage of formulation features that alert formulators to specs that exceed the finished good’s nutritional target values, then manually or automatically adjust the ingredient levels that contribute to the nutritional property value.

Formulation Costs:

Manufacturers sometimes need to balance consumer preferences with cost-effectiveness and production efficiency.

- Perform a side-by-side cost analysis of specifications by comparing ingredient, labor and consumable costs, as well as additional shipping and miscellaneous costs.

Fluctuating Prices Of Ingredients:

Certain commodity prices are subject to fluctuations in supply and demand. This can make it difficult for manufacturers to forecast costs and prices.

- When calculating estimated cost of finished products, ingredient costs are calculated using the item’s inventory valuation method, such as current and average methods.

Shelf Life:

Natural ingredients can deteriorate over time, which can affect the quality and flavor of the seasoning, which can lead to expired inventory in the warehouse or worse yet, soon to be expired products on the retailer’s shelves, which will be returned.

- Allocate the right inventory in batch jobs by considering the expiration dates and rotation methods of lot controlled raw materials

Product Consistency:

The goal is to achieve the same taste, texture, color, and quality results for a produced food product. Achieving this consistency is challenging as natural ingredients and variations in processing parameters affect the final product.

- Manage the variable characteristics of ingredients then adjust the equipment and environmental settings, based upon quality trend analysis.

Supply Chain Disruptions:

Vendor delivery issues can cause distributions in production scheduling and execution.

- With flexible batch job features, batch jobs can be sized based upon raw material availability, as well as batch job formula specifications revised should raw material alternative/substitutions be needed.

Seasonal Demand:

Food manufacturers must be prepared to adjust their procurement and production plans accordingly to meet fluctuations in demand during the year.

- With advanced planning & scheduling (MPS & MRP), sales forecasts and seasonal demand parameters contribute to the application’s automated forecasting of batch jobs and purchase orders.

Regulatory Compliancerns:

Food manufacturers must comply with a range of regulations, such as food safety standards, labeling requirements, and traceability & recall mandates. For example, achieving and maintain an advanced food safety certification can be a challenge.

- Take advantage of the software’s nutritional labeling feature and graphical bi-directional traceability tool that exceeds BRC / SQF product traceability & recall codes.

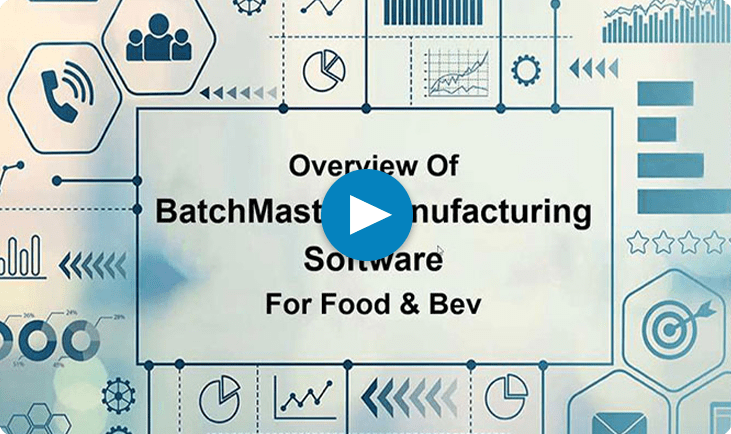

KEY MODULES FOUND IN OUR FOOD MANUFACTURING APPLICATION

BatchMaster Software food manufacturing modules include recipe and packaging management, costing, inventory, production, quality, planning, scheduling, BRC/SQL traceability & recall, FDA compliance, and mobile warehousing. All of these food manufacturing modules are available in our add-on food manufacturing application, which can be integrated to one’s existing financials, specifically QuickBooks, Sage 100 & 300, Microsoft Dynamics GP and SAP Business One. Our add-on food application is available on premise and in the cloud.

UPGRADE TO OUR ERP FOR FOOD SOLUTION

BatchMaster ERP is the enterprise resource planning system designed to meet all of your critical business needs within a single, cohesive platform.

As an OEM partner of SAP. BatchMaster’s best-in-class business and industry capabilities for manufacturing have been natively embedded into SAP Business One, SAP’s market-leading and future-proof platform for small and midsize enterprises.

BatchMaster Software implements and supports our ERP application on our customers’ local server and in the cloud without the use of any third party consultants.

KEY MODULES FOUND IN OUR FOOD ERP APPLICATION

KEY BENEFITS OF OUR FOOD MANUFACTURING ERP SOFTWARE

1. Accelerate Product Development

- Track progress of samples

- Allow multiple developers to work on separate recipe and packaging specs

- Employ USDA and Genesis nutritional information

- Dynamically adjust recipes to meet nutritional, physical and cost target values

- Perform side by side comparison of specs

- Initiate multi-level approval workflows

- Generate FDA nutritional and ingredient labels

2. Quickly Scale Up Production

- Dynamically adjust specs and yields based upon available inventory

- Reserve inventory for customer orders

- Auto link and schedule batch jobs

- Manage equipment and resource availability and capacities

- Auto generate lot numbers for intermediates and finished goods

- Execute production related tasks via mobile devices

- Automatically backflush inventory

3. Ensure Quality

- Establish QC and QA inspection, checklist, and special instruction libraries

- Mandate task acknowledgements and quality data collection

- Auto disposition any sub standard inventory

- Generate customized COA reports

- Manage deviation and non conformance situations

4. Control Costs

- Define fixed, tiered and variable labor costs within specifications

- Identify costs of consumables

- Run what if cost analysis

- Dynamically adjust recipes to meet cost target values

- Consolidate demand using MRP and MPS for discount bulk purchases

- Optimize resources utilization based upon MRP and MPS planning

- Analyze expected vs actuals

5. Ensure Compliance

- Dynamically adjust recipes to meet label claims

- Generate FDA approved nutritional fact panels

- Generate bidirectional lot traceability reports

- Maintain full version control and audit history

- Auto assign lot numbers during receiving and production

- Track the variable characteristics of inventory

- View simultaneous dual units of measure

- Select the right inventory based upon expiry dates, certifications and status

- Reserve inventory for batch jobs

- Optimize inventory levels using automated planning and procurement

- Determine planning horizons and calendars

- Consider vendor delivery, order forecasts and planned production

- Prioritize customer orders

- Consolidate demand

- Link and schedule related batch order and runs

- Generate synchronized purchase orders

- Inbound receiving and putaway tasks

- Batch production functions and WIP inventory movements

- QC tests and special instruction tasks

- Outbound pick, pack and ship tasks

- Inventory adjustments, cycle counts and warehouse transfers

- Access real-time, accurate actionable data

- Employ drill down, role-based dashboards with graphical components

- Get quick data access using “favorite” shortcuts

- Customize industry inquiries and reports, as well as run ad-hoc queries

CONTACT US / REQUEST A DEMO

DOCUMENTS

Food Brochure

A 6 page brochure addressing the challenges and requirements of food manufacturers, and the features and benefits of BatchMaster ERP for Food.

Functional Checklist

A 2 page data sheet describing key functions used in formulation, production, quality and other processes that are critical in food production.

VIDEOS

Speed Product Development

See the food development software features you need to quickly create recipes and finished goods and move them from R&D into production.

Streamline Production

Learn how our food production software can quickly and easily streamline and scale up your operations and better manage your inventory.

Comprehensive QC & QA

Discover the quality control & quality assurance software features that can ensure the continuous flow of high quality products as you scale up production.

Recall

See how our lot management capabilities enable you to expedite traceability and recall activities

WHAT OUR CUSTOMERS SAY