End-to-End ERP Software to Solve Bakery Manufacturing Challenges

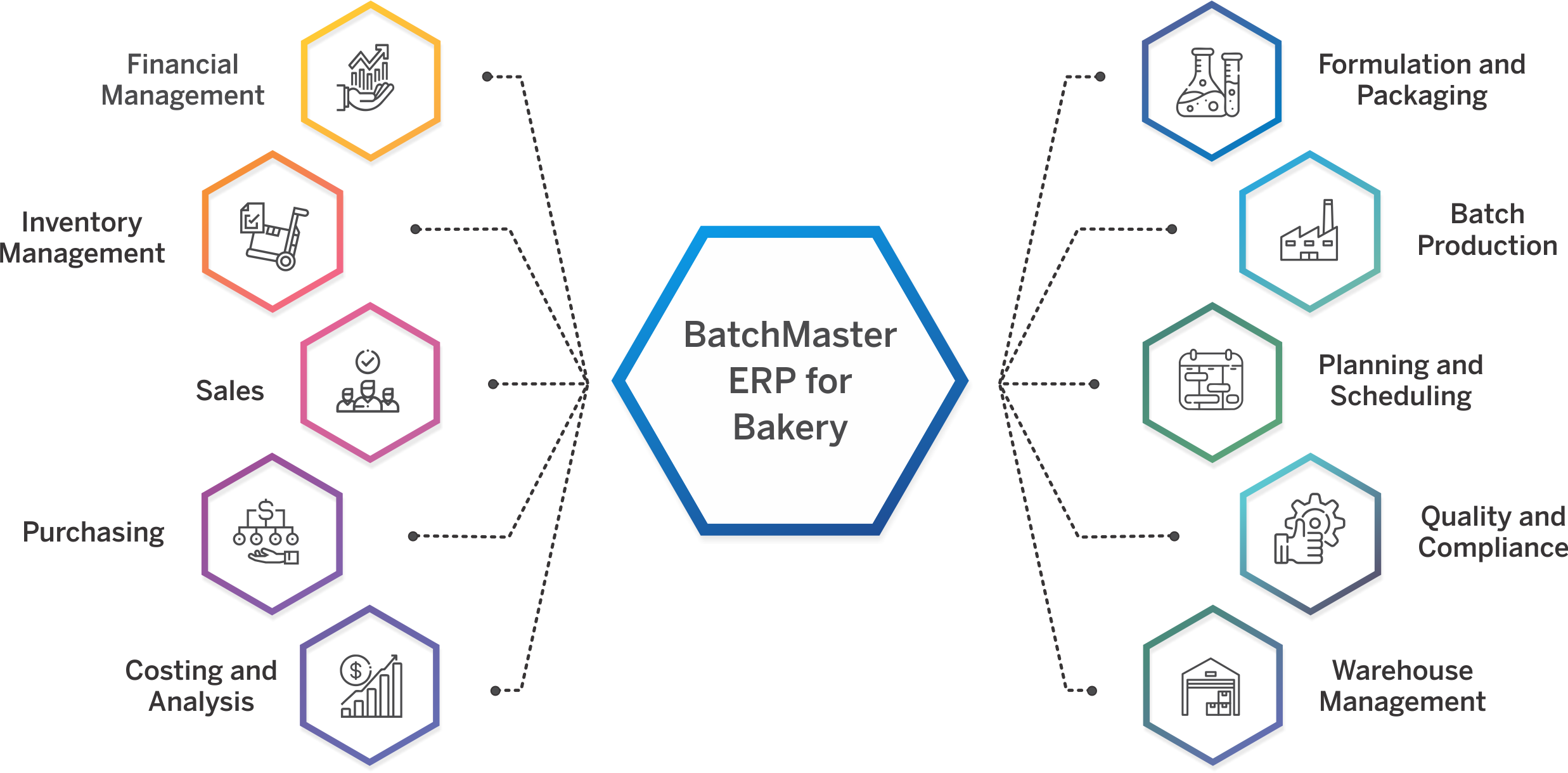

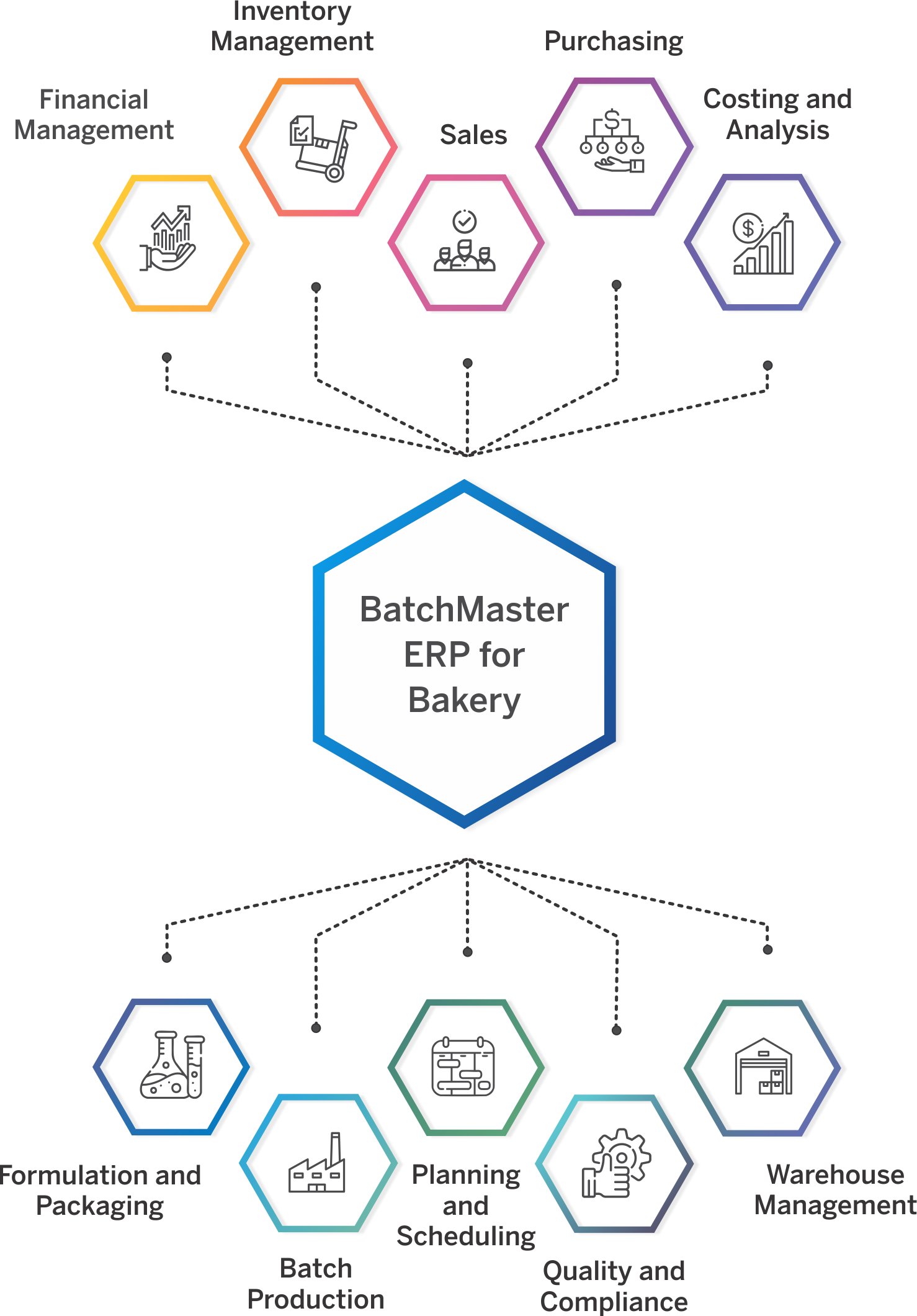

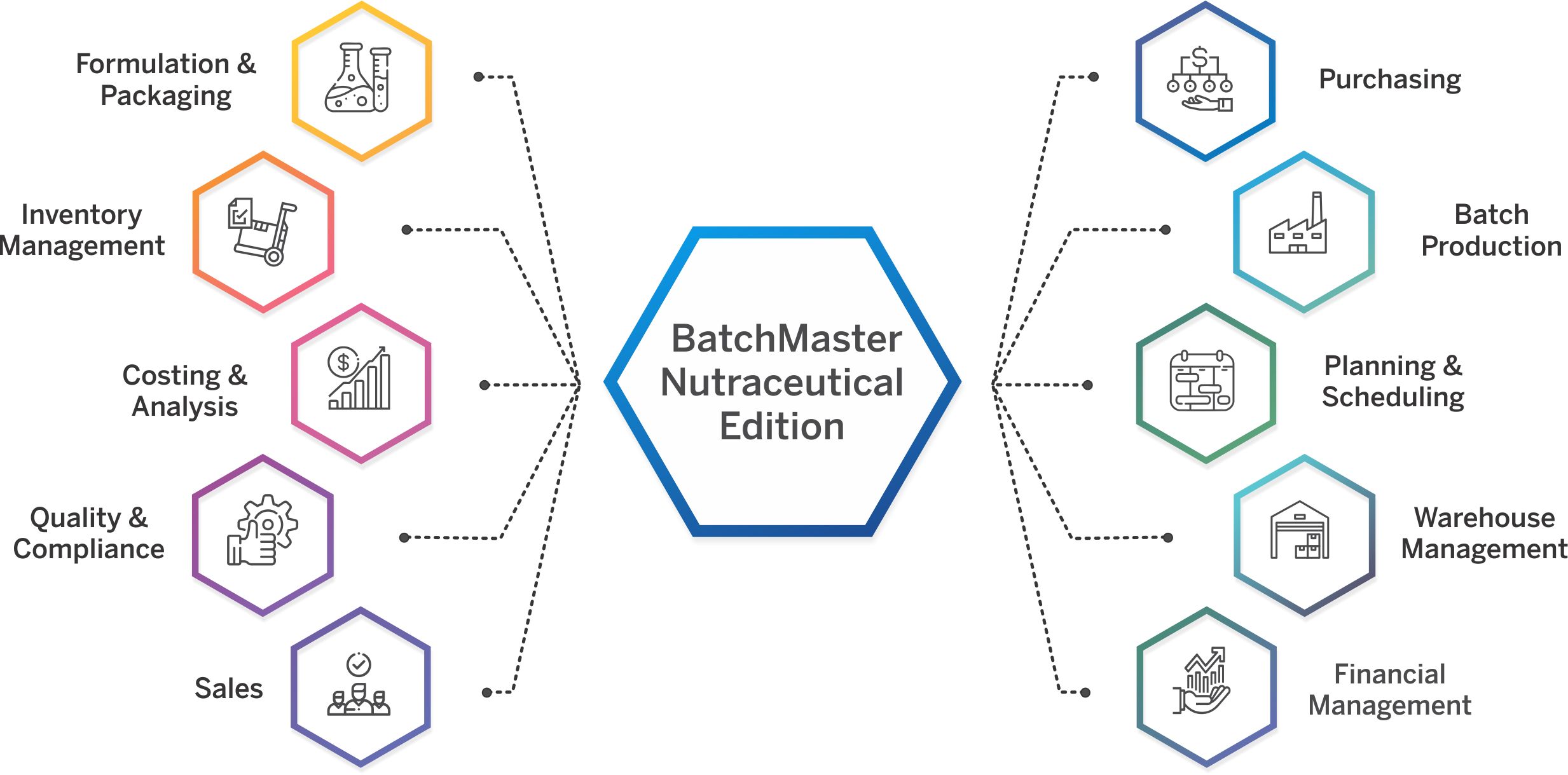

BatchMaster ERP for Bakery is a specialized ERP software designed to manage and streamline your bakery manufacturing needs. Whether you private-label, co-pack, or produce your own line of bread, snacks, pastries, or other bakery goods, BatchMaster ERP handles everything from ingredient sourcing and recipe management to production planning, quality, compliance, and beyond.

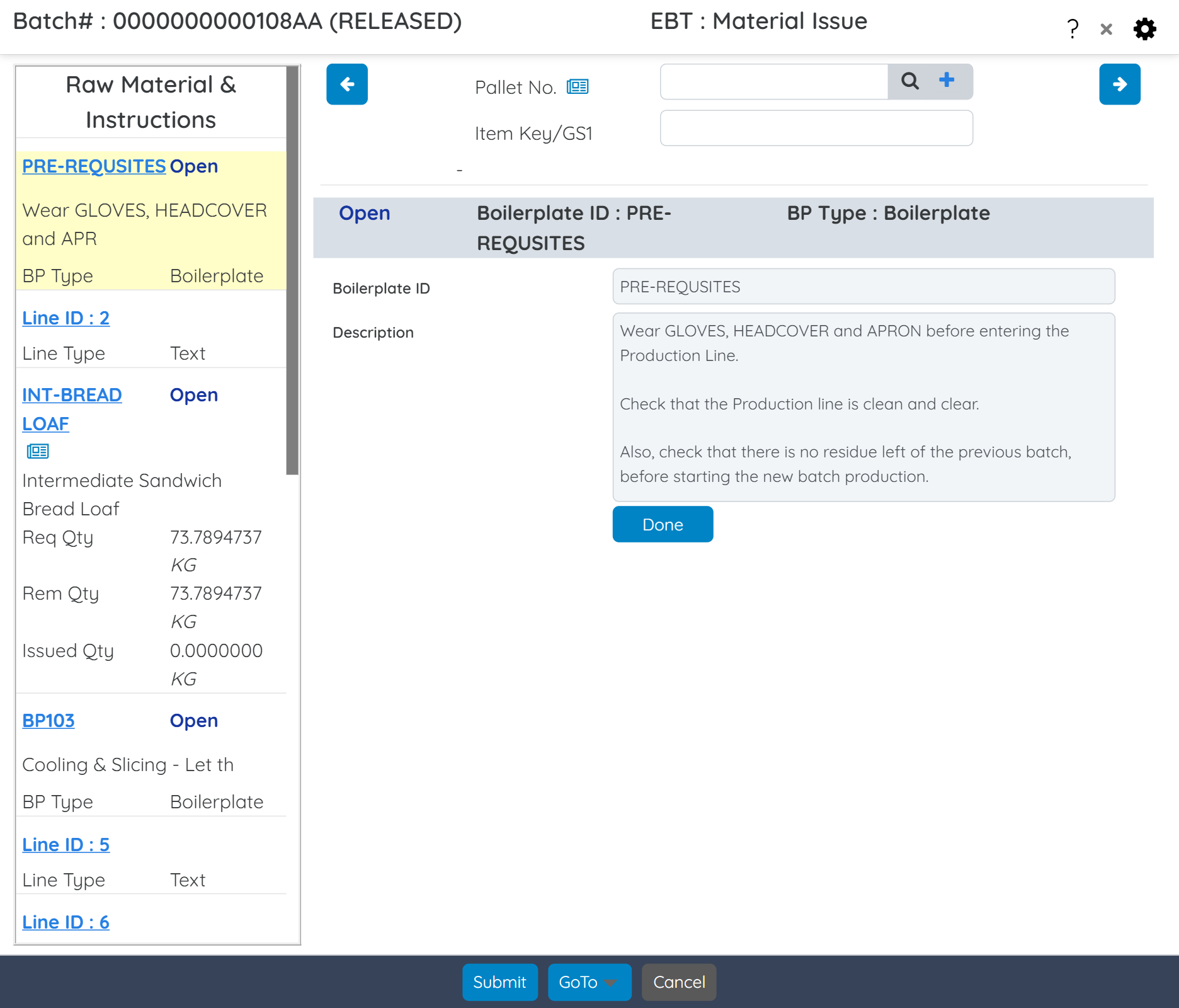

- Manage end-to-end production from mixing and scoring to baking, slicing, cooling, and packaging

- Handle multiple business models efficiently, whether its own-brand manufacturing, contract manufacturing, or private labelling

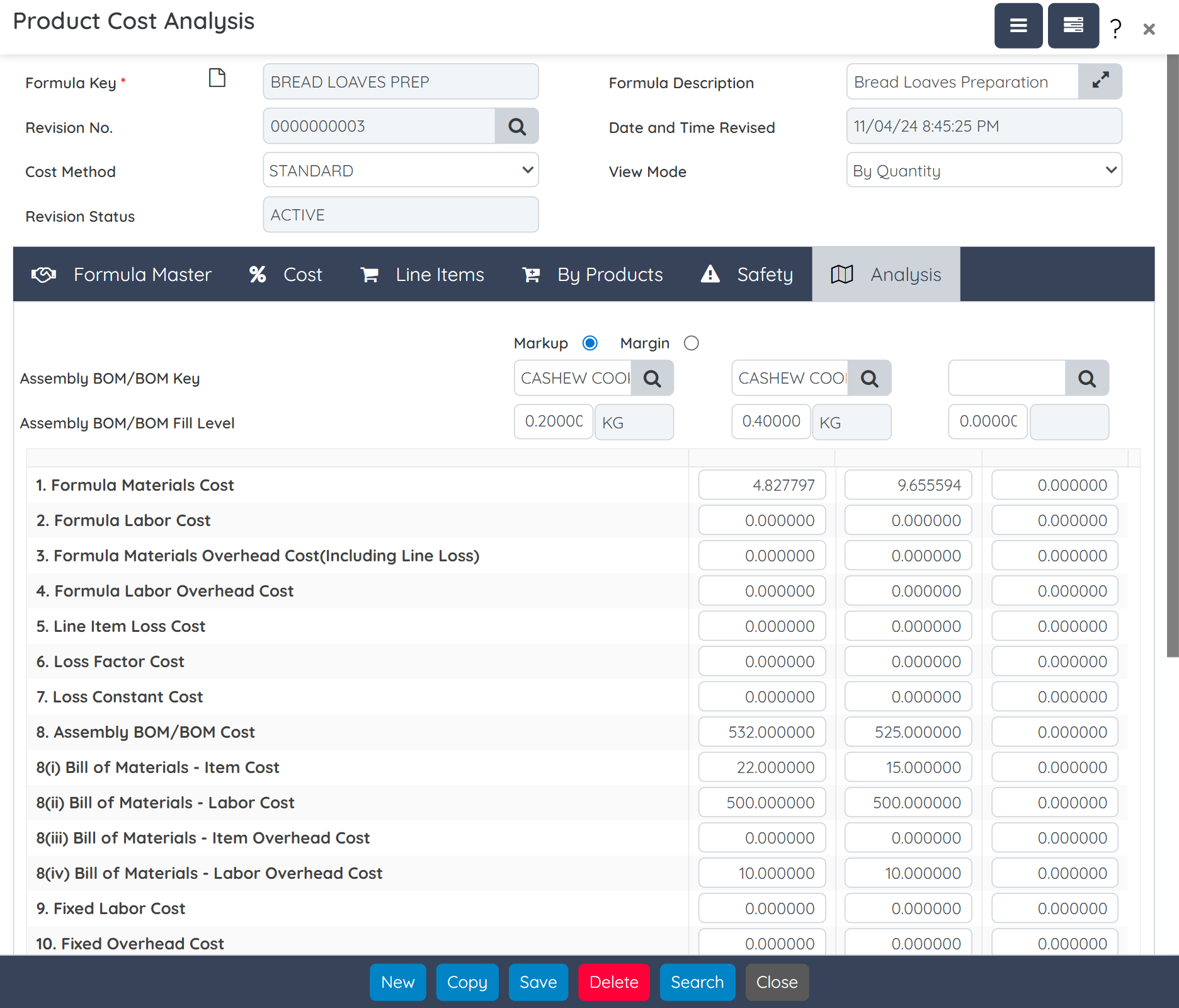

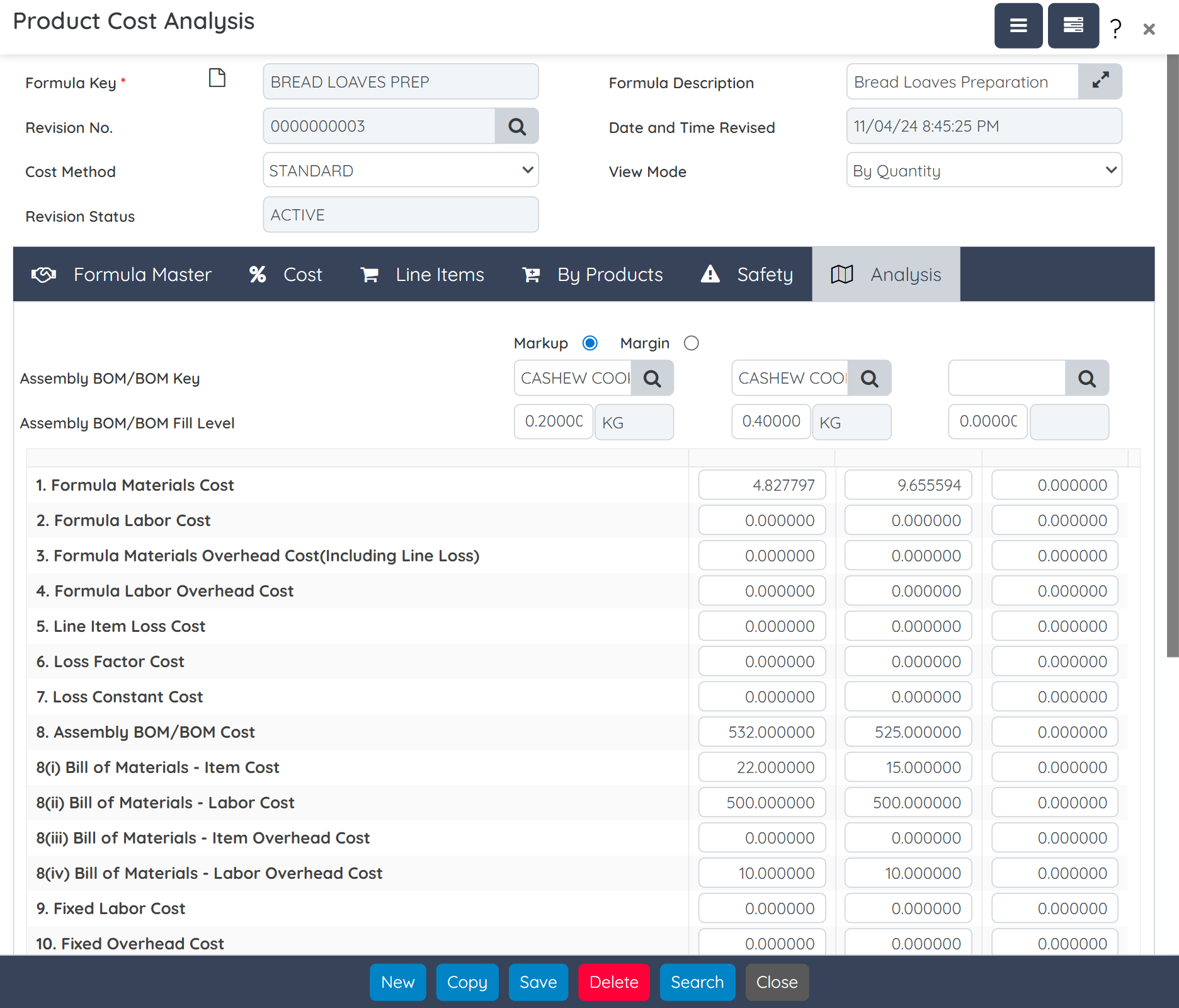

- Optimize production scheduling, product costing, reporting, and analysis

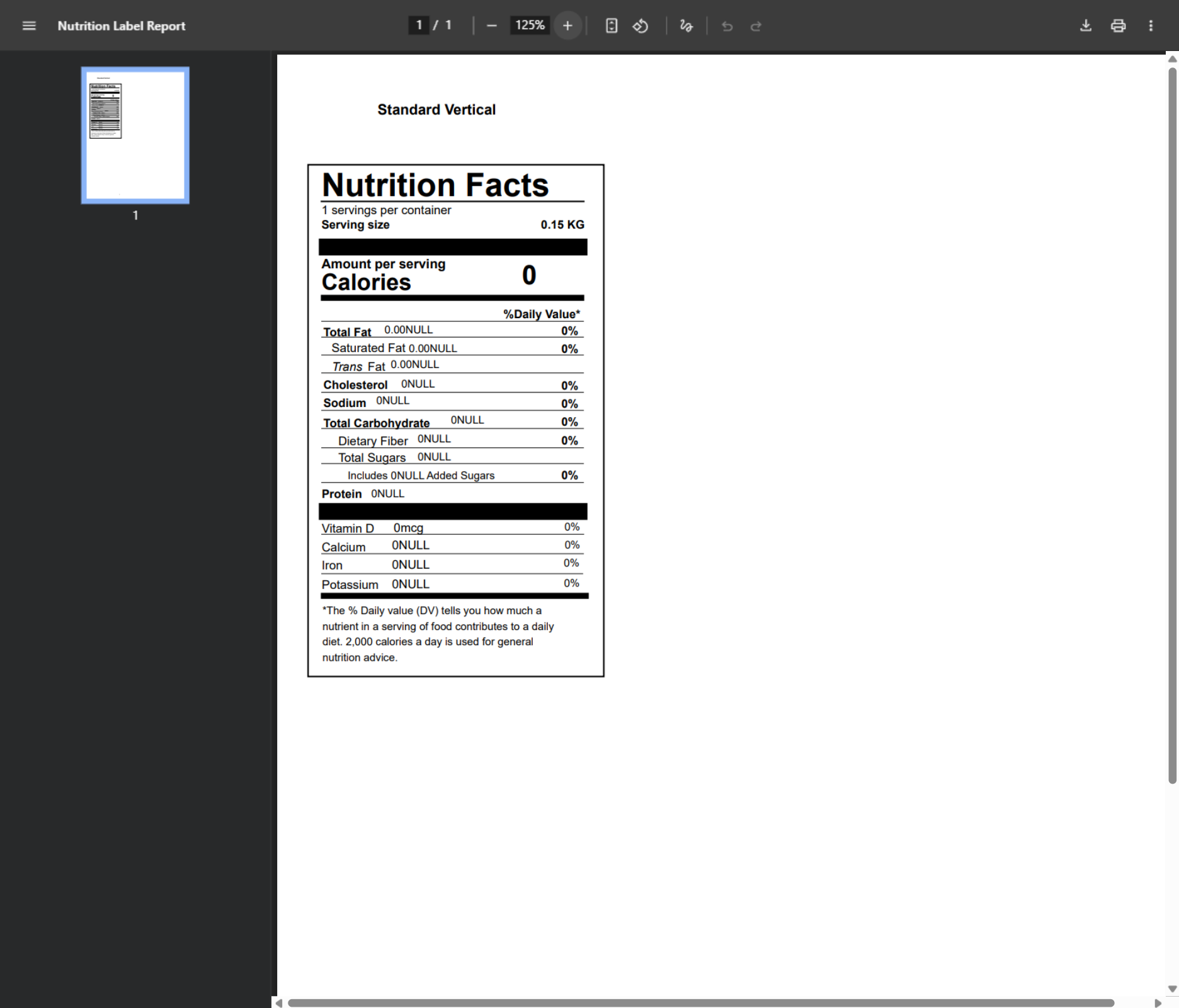

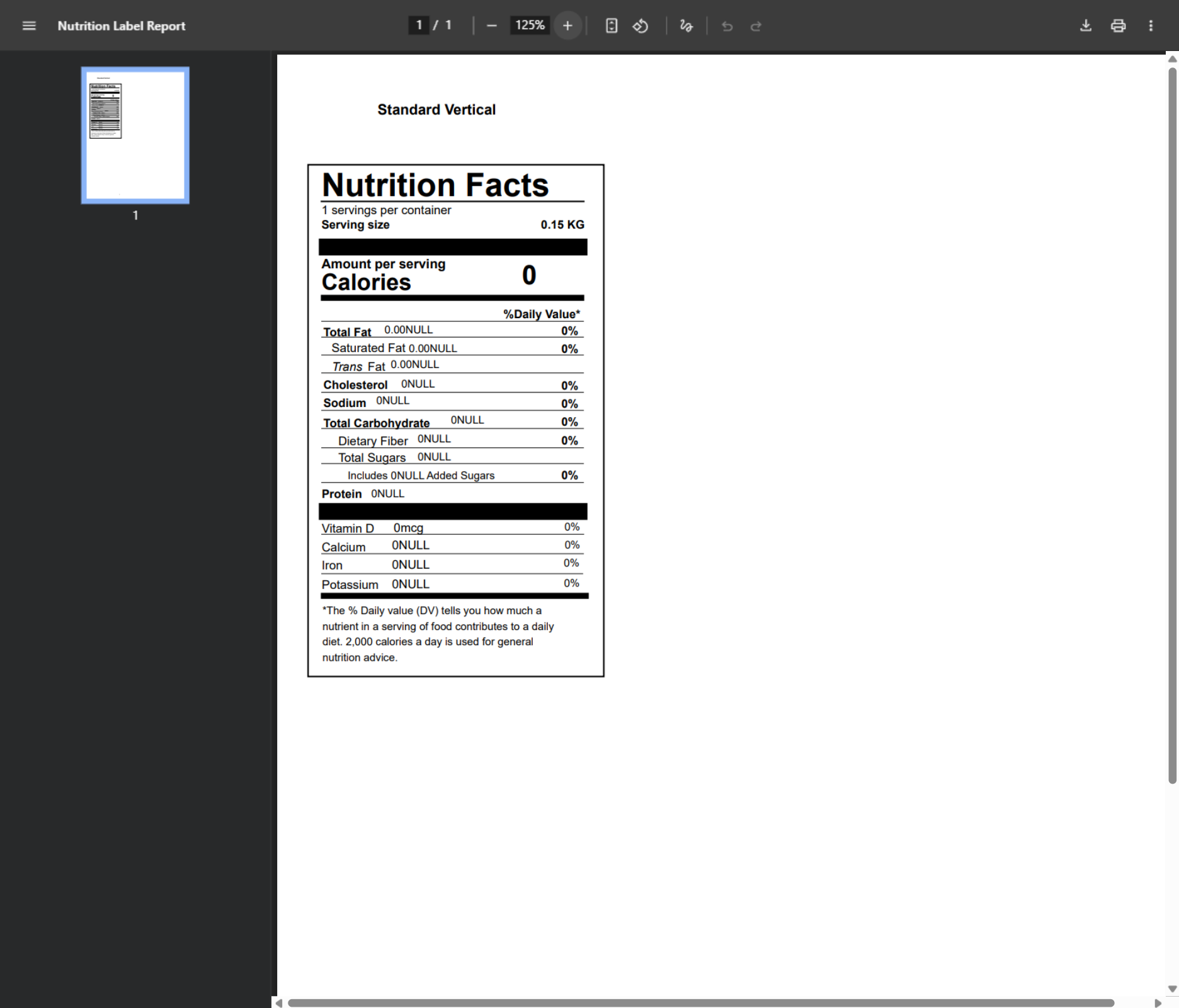

- Generate FDA-compliant Nutrition Fact labels and ingredient statements, including non-GMO, gluten-free, and allergen-free claims

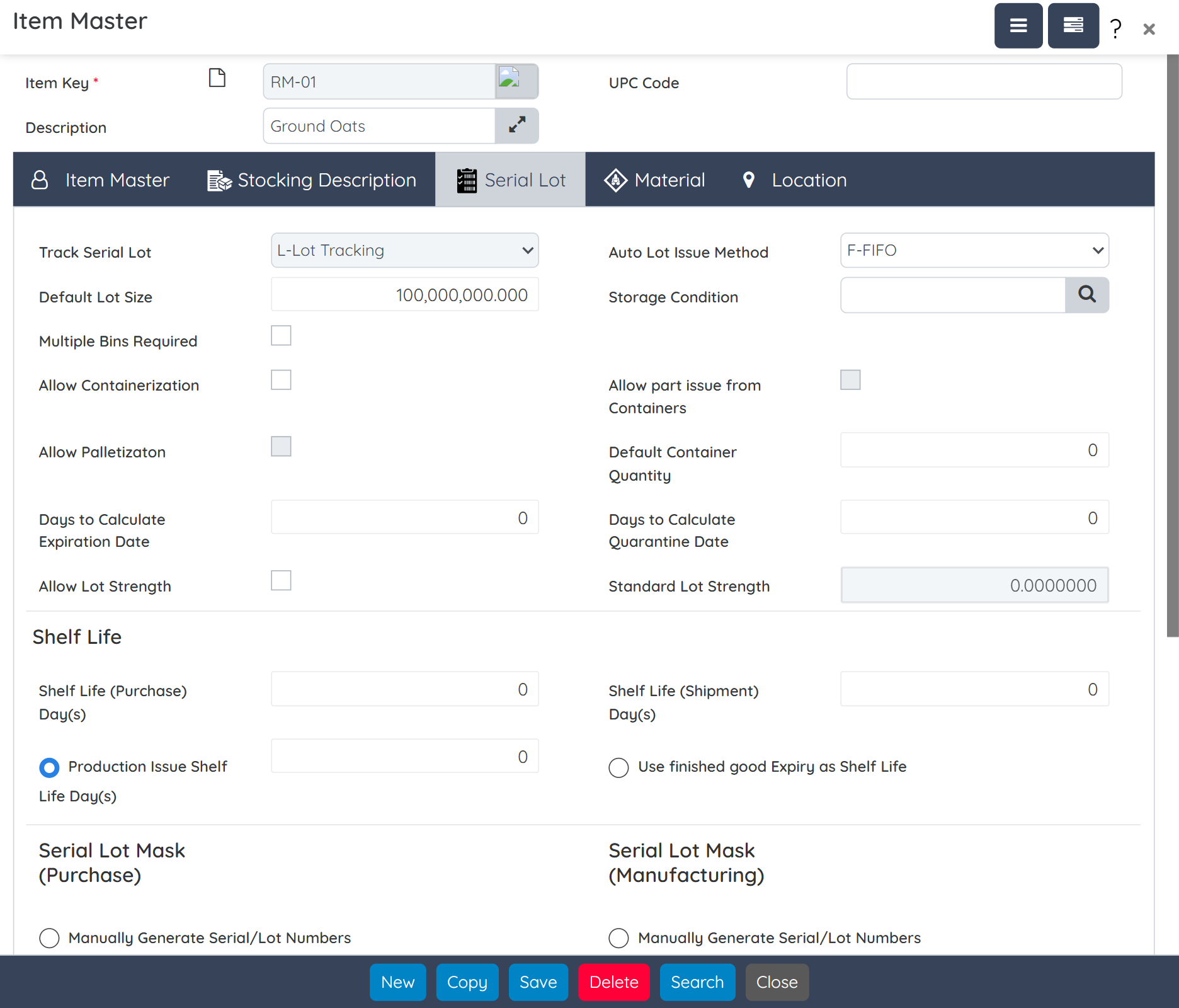

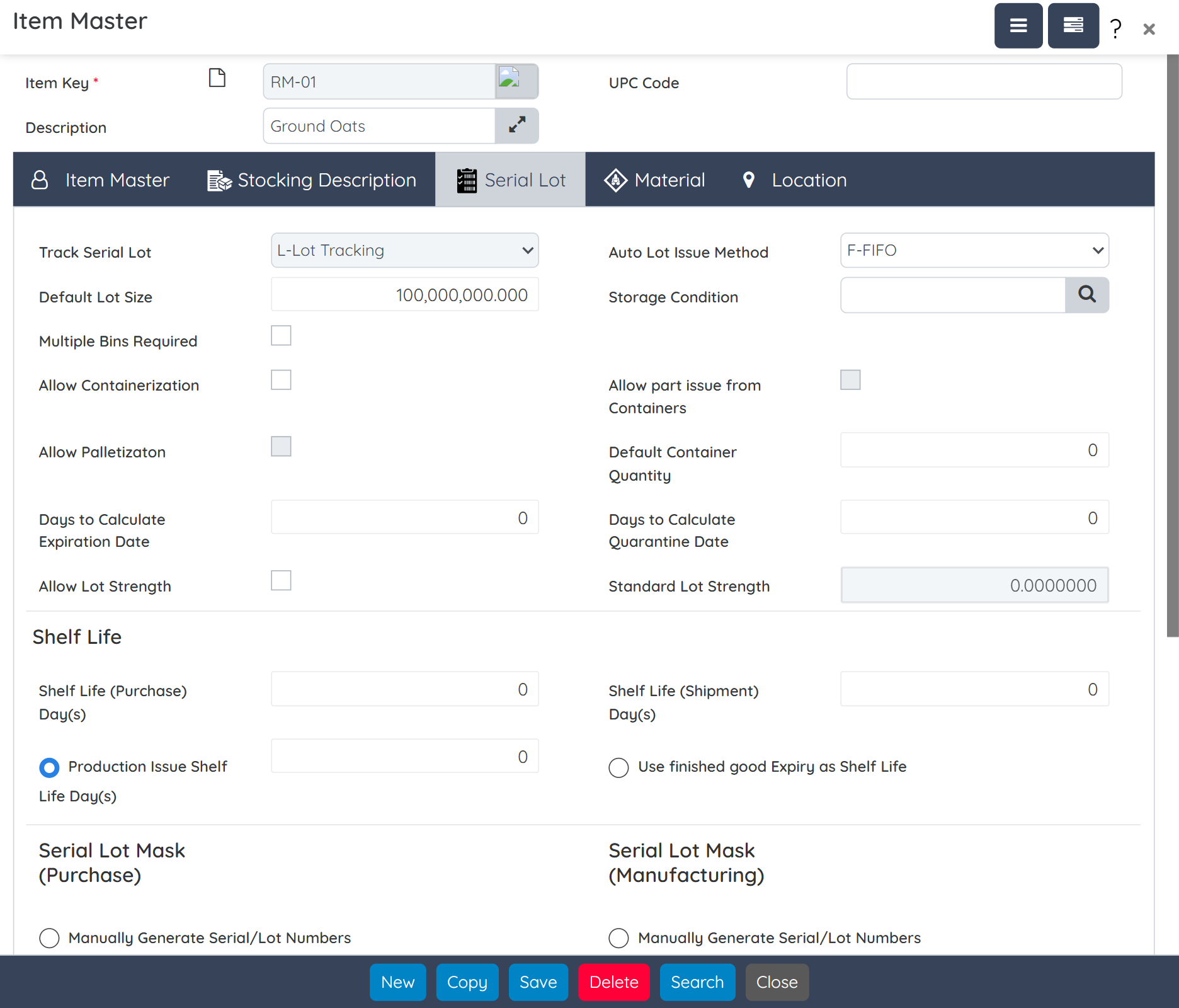

- Enable real-time batch monitoring, shelf-life/expiration date management, lot traceability, and more

- Gain visibility across departments with role-based dashboards and reports

Bakery ERP Designed to Meet the Unique Demands of Bakery Manufacturing

Trusted by Leading Bakery Manufacturers

Specialized Capabilities for Bakery Operations

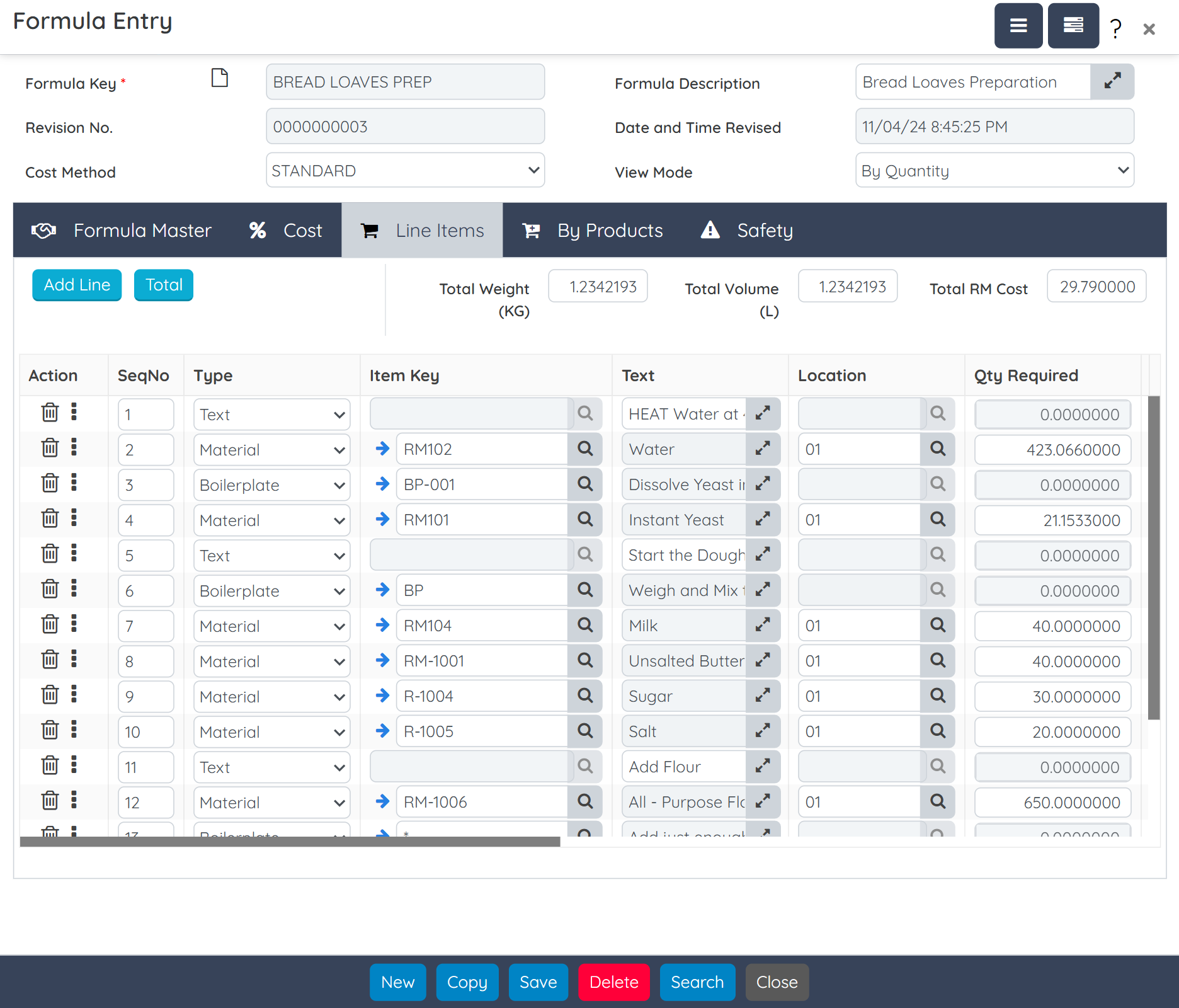

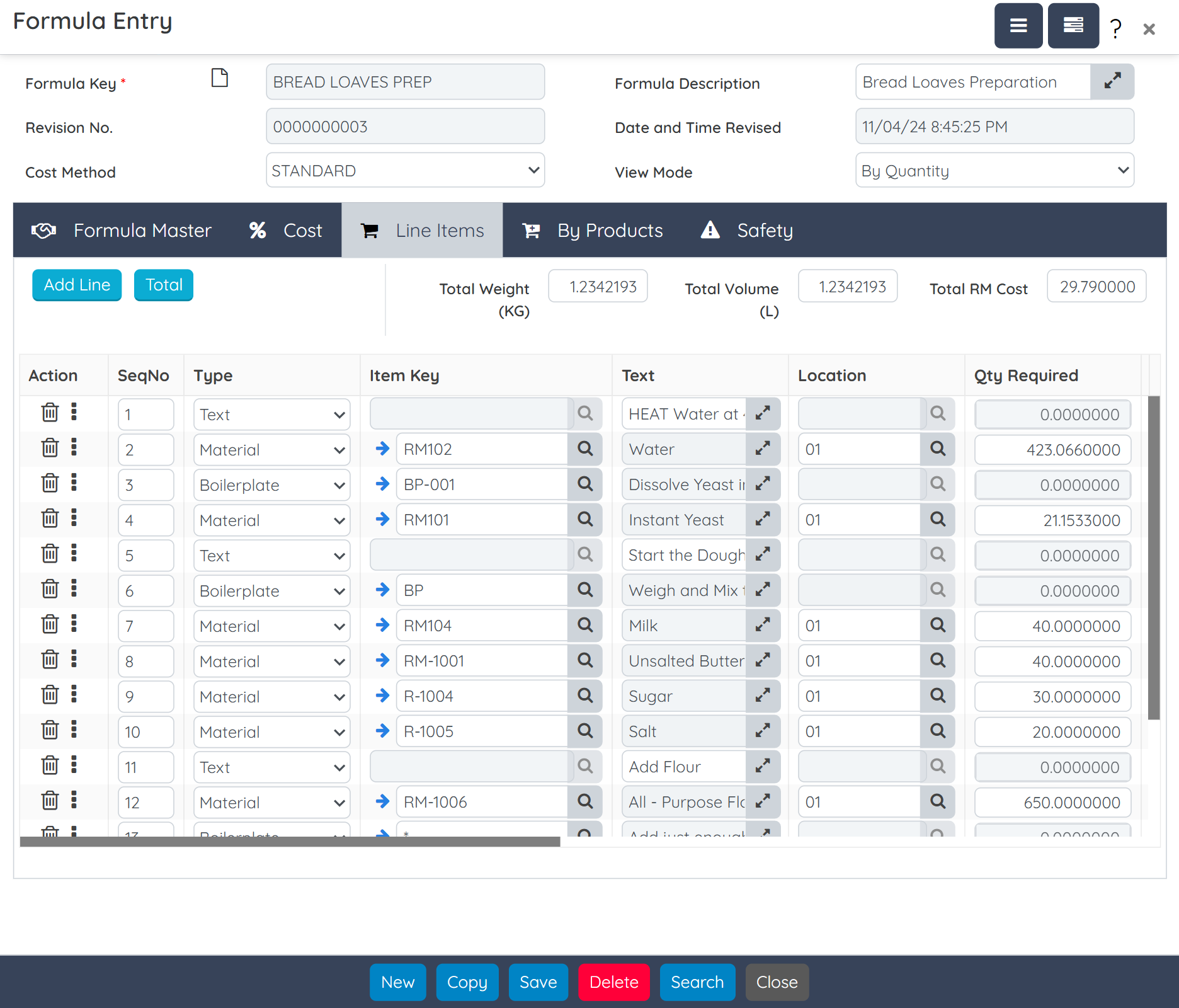

Manage bakery recipes and formulas with control over fermentation stages, enzyme behavior, moisture levels, and ingredient ratios for consistent texture and taste.

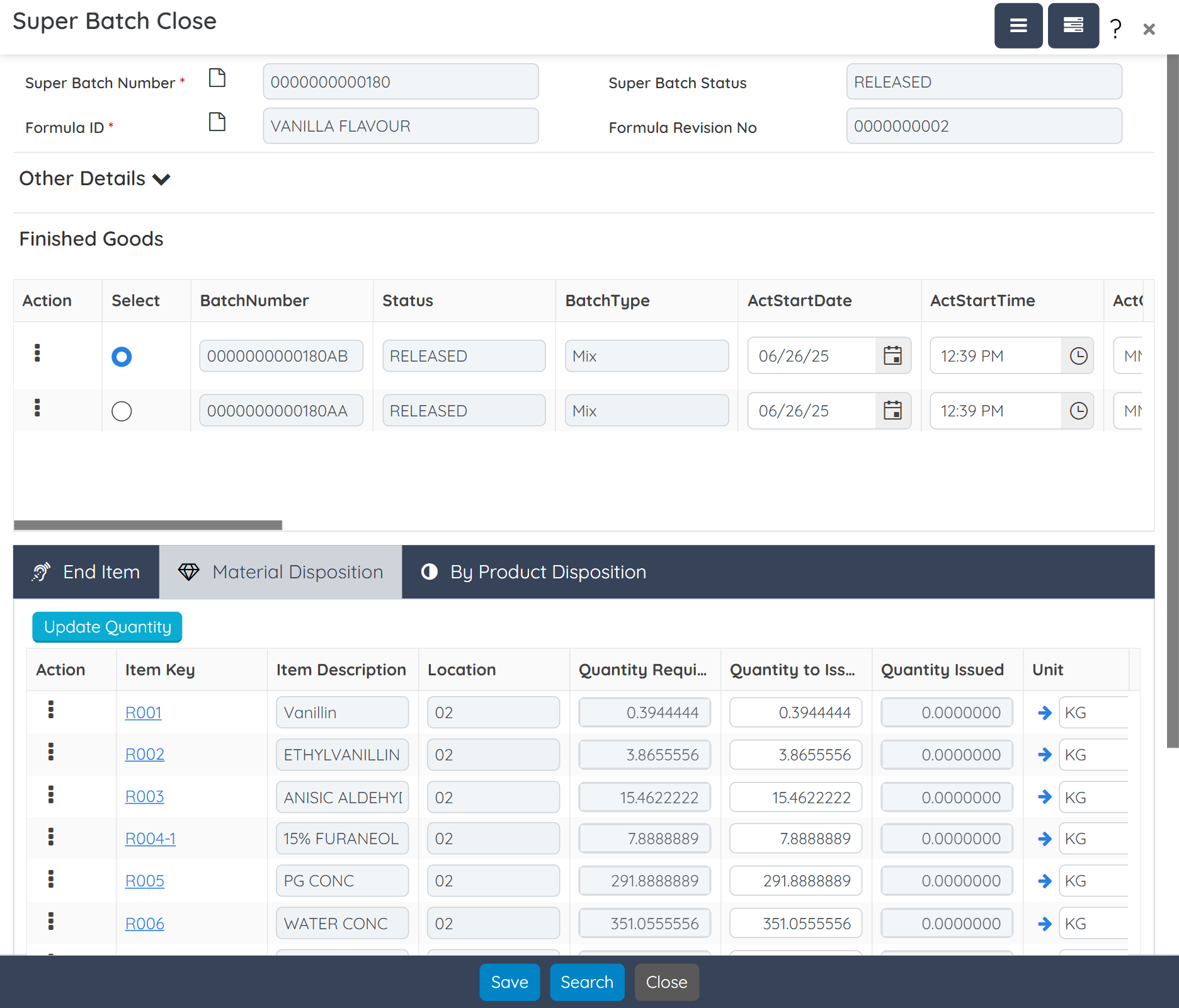

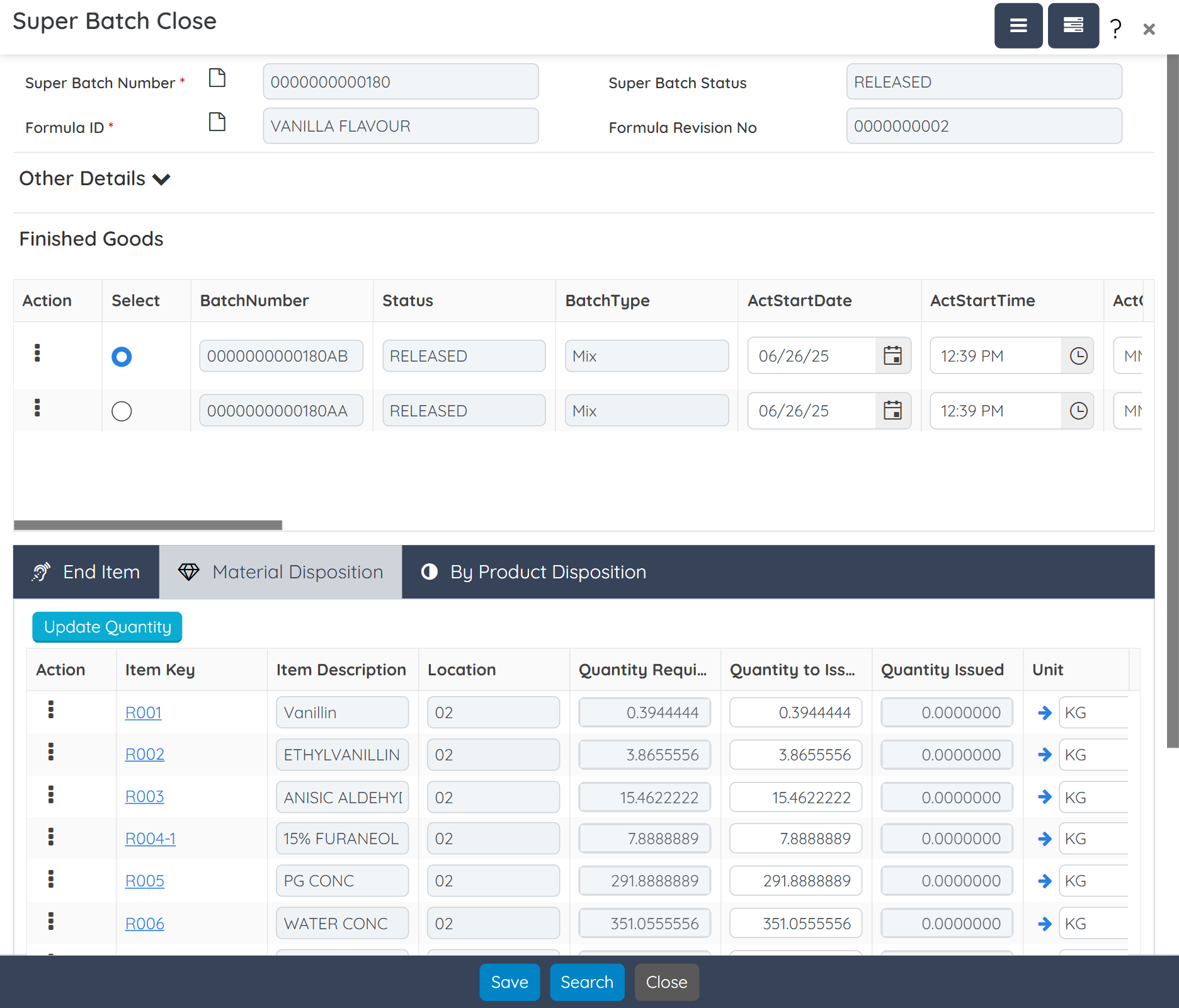

Control batch sizes and sequencing for doughs, batters, fillings, and icings, including co-products with precision. Manage multiple batches in a single run using super batch functionality.

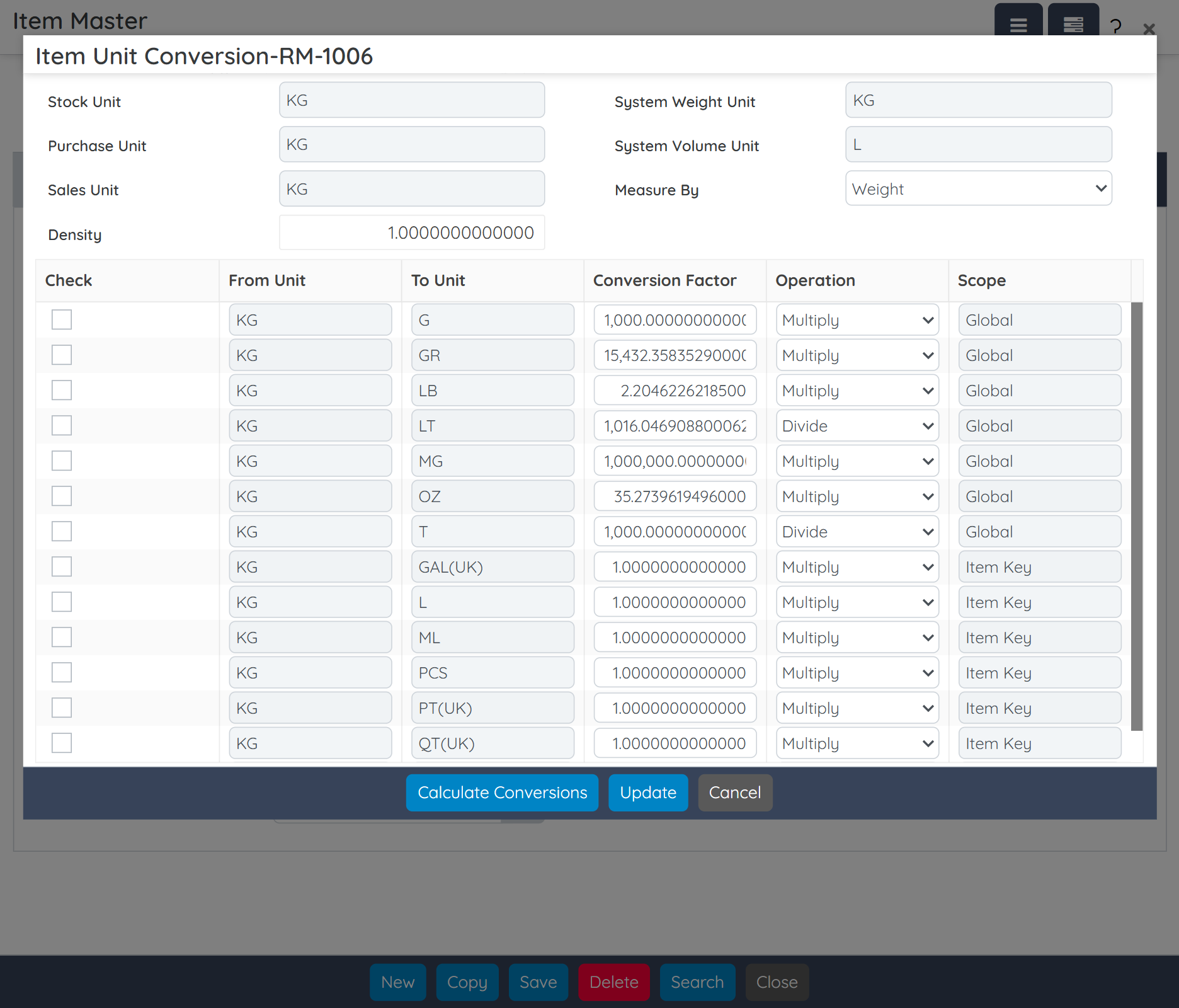

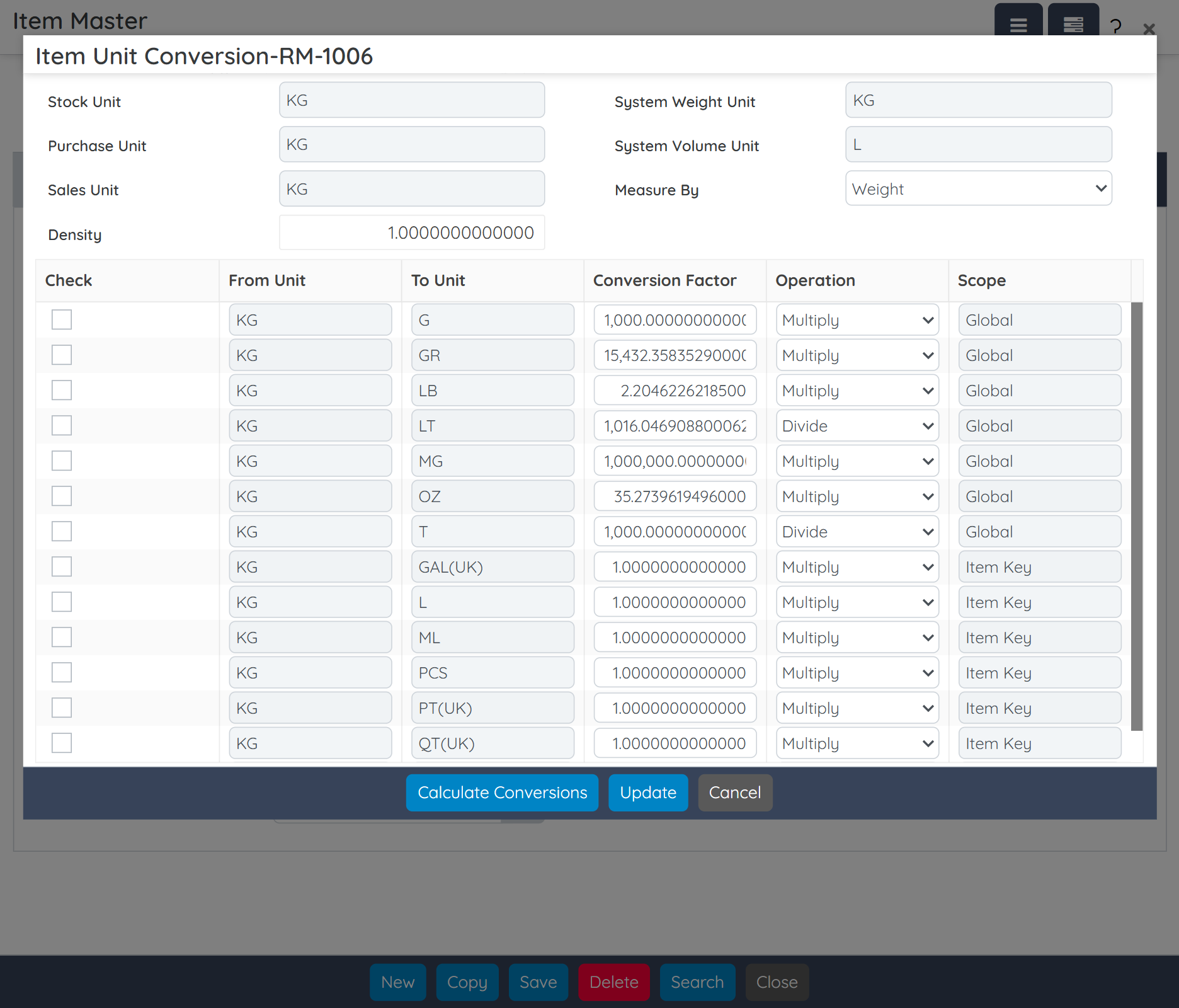

Seamlessly manage multiple units such as weight, volume, and count, critical for handling ingredients like flour, eggs, and liquids in bakery production.

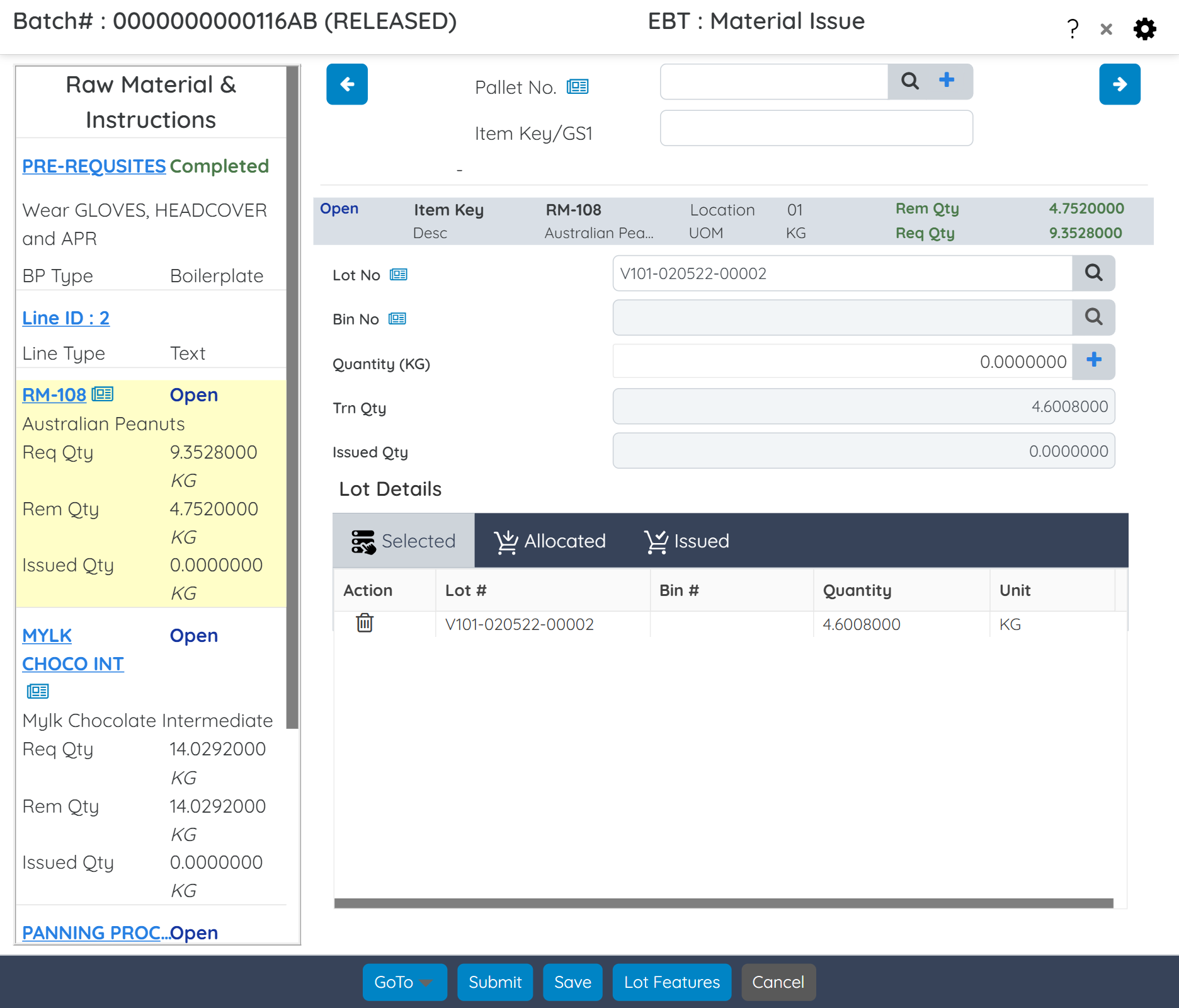

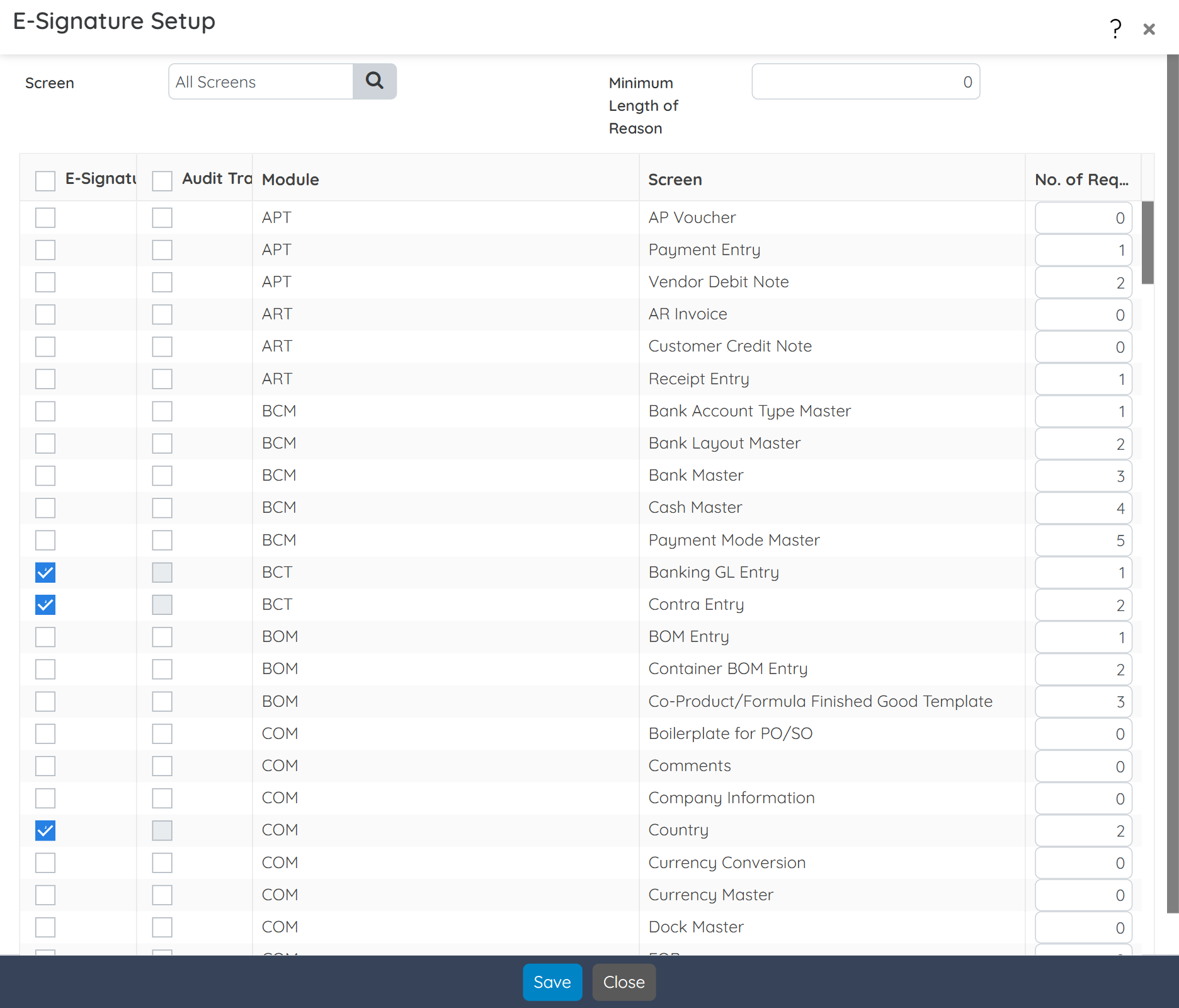

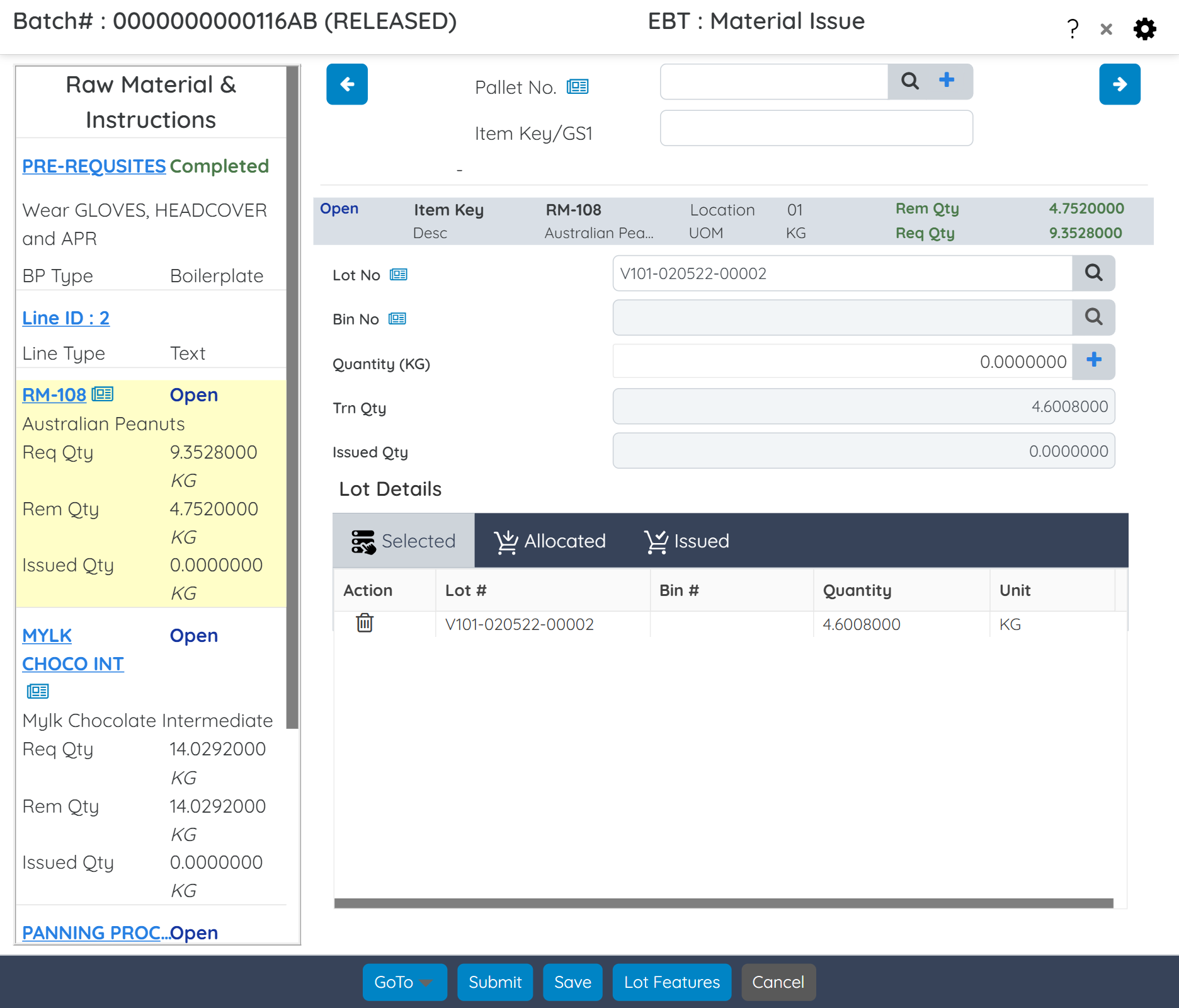

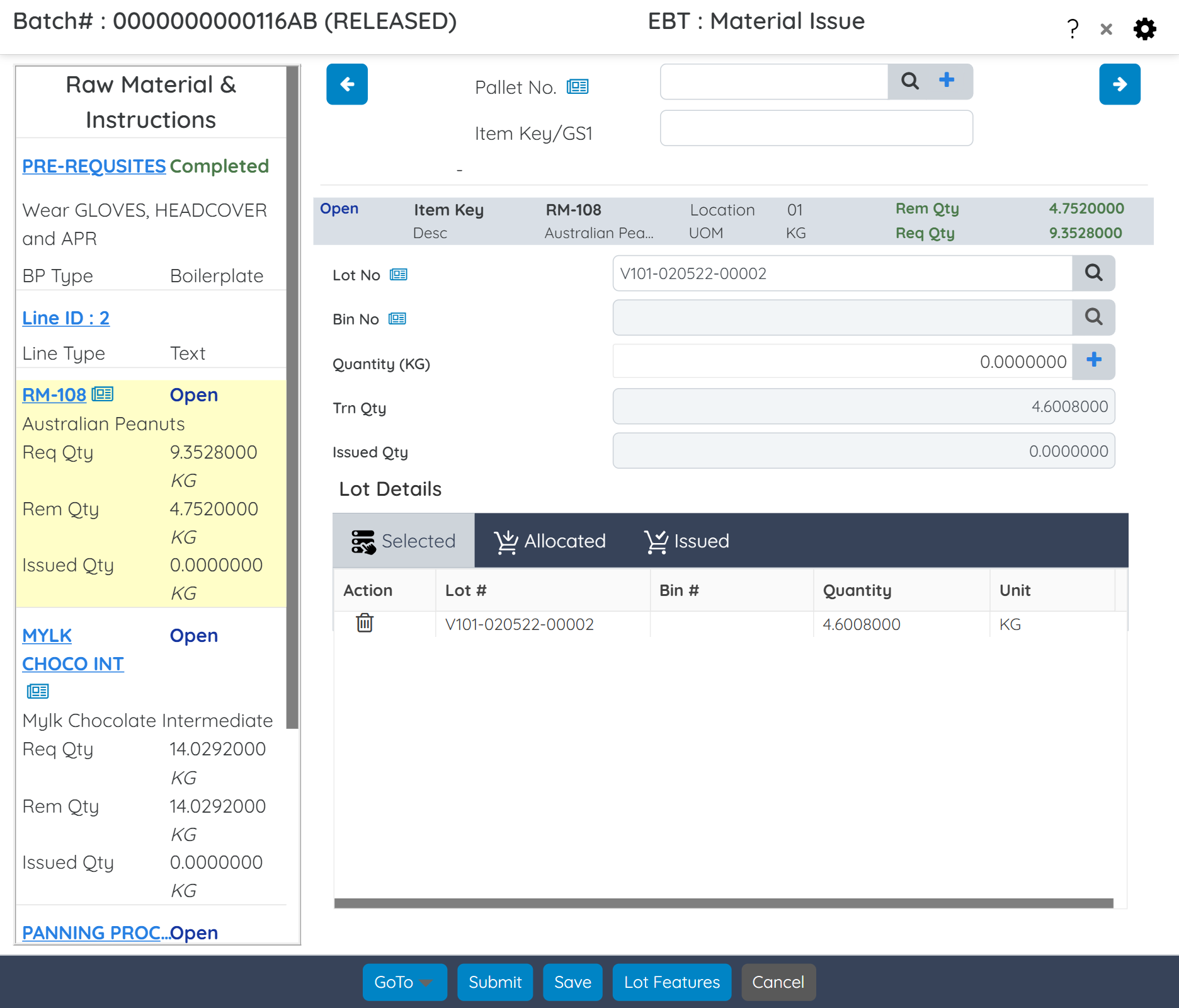

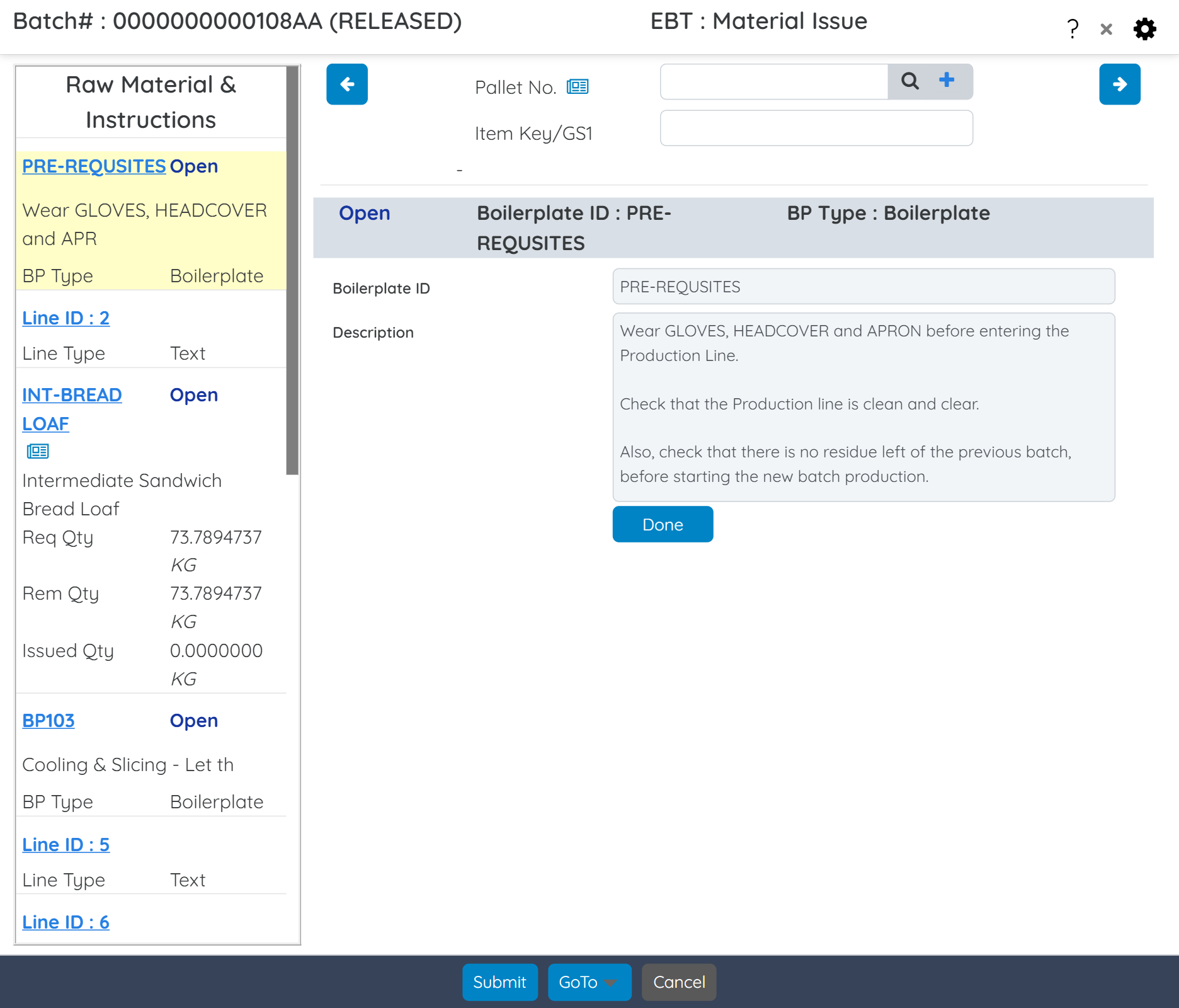

Digitally record production steps, ingredient usage, and operator inputs with electronic batch records for complete traceability and compliance audits.

Capture SOP adherence, ingredient weights, and real-time operator activities directly from the shop floor using integrated MES and weight sheets.

Track bakery products and ingredients by shelf life, batch age, and storage conditions to ensure freshness and minimize spoilage.

Automatically calculate nutritional values based on recipe inputs to generate bakery-specific labels for calories, fat, sugar, and serving size.

Track allergens like lactose, gluten, and nuts, and ensure accurate claims and clean labeling for consumer transparency.

Plan and schedule baking cycles, oven loads, and shift timings while aligning with demand forecasts and raw material availability.

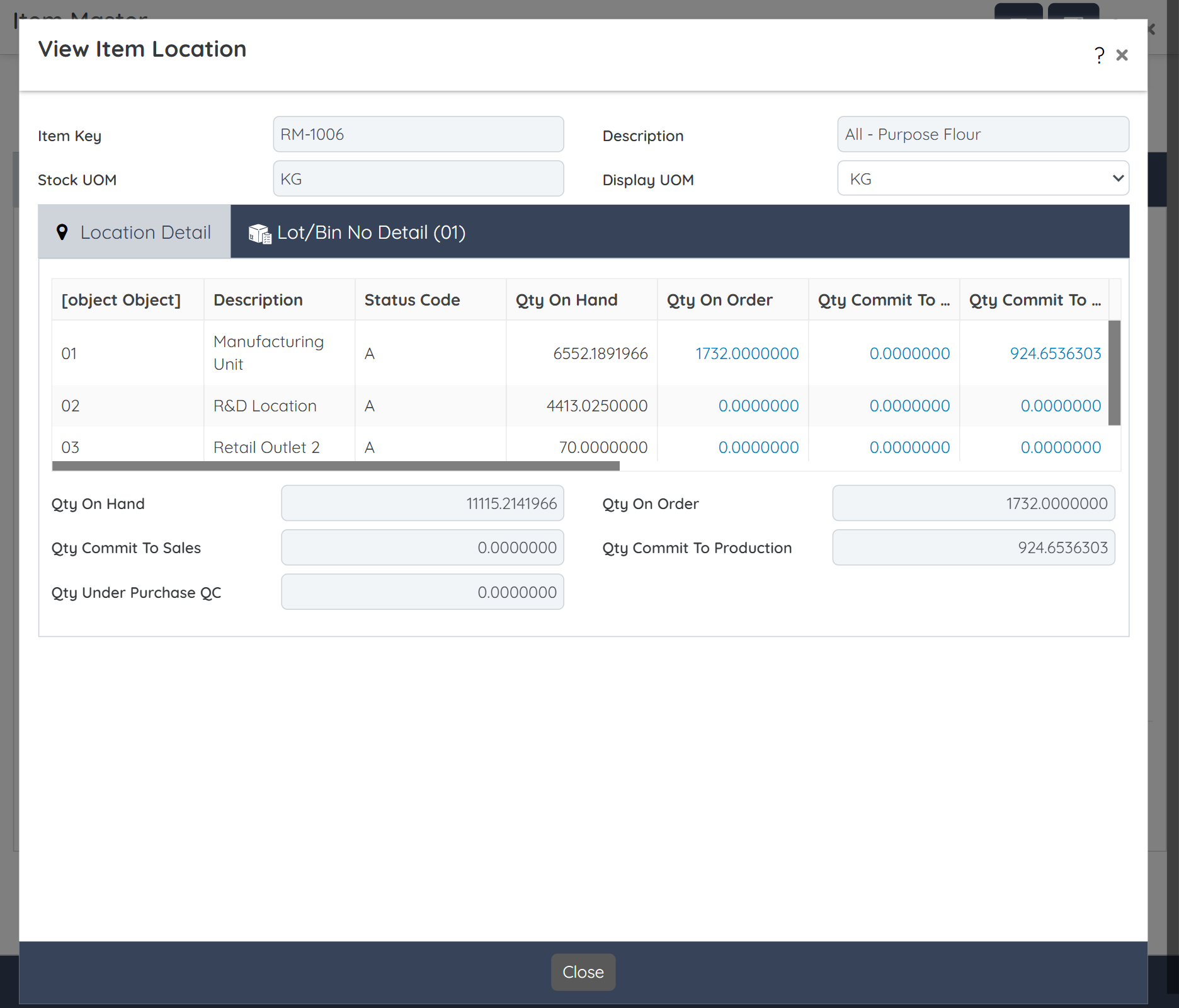

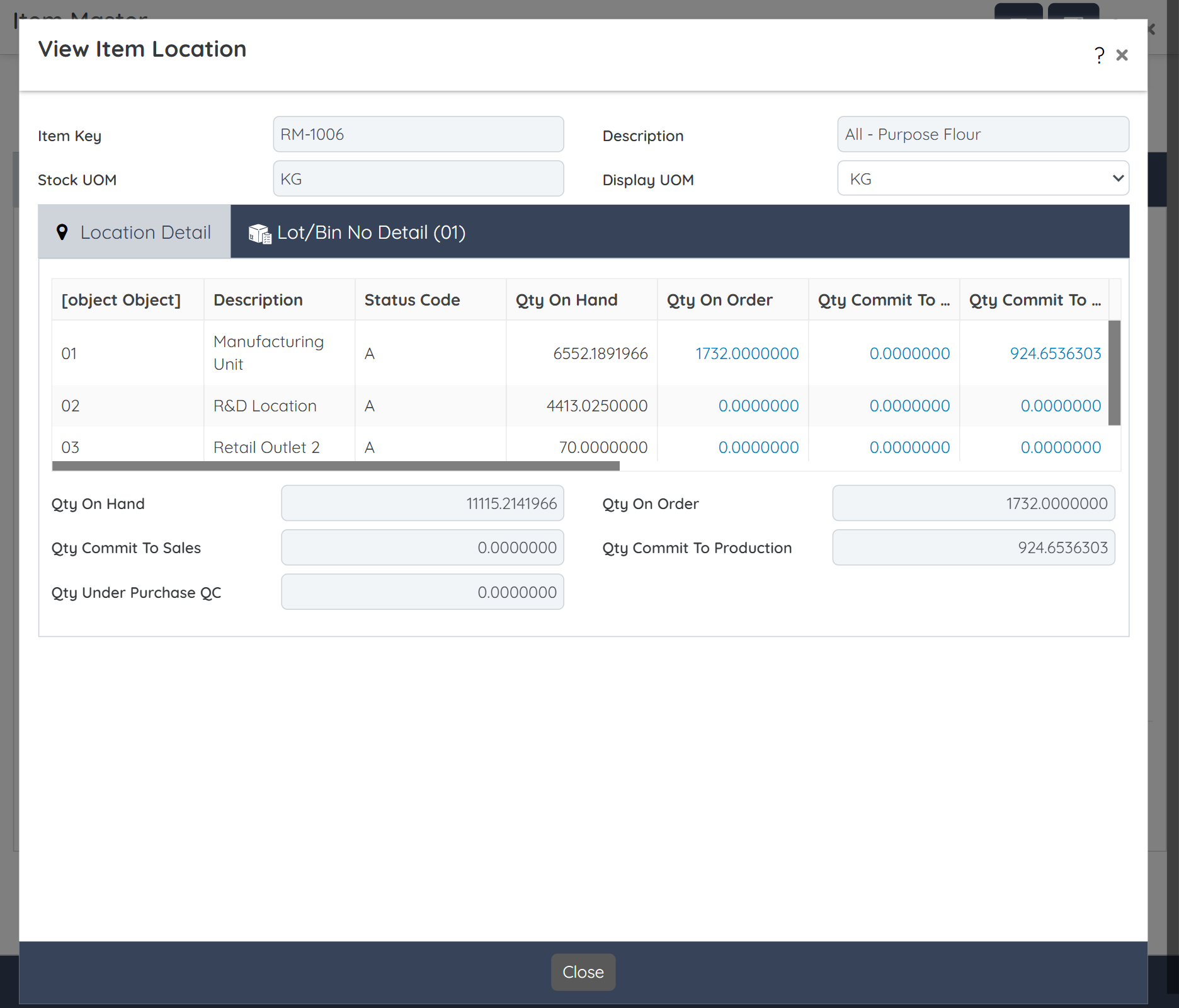

Get live insights into inventory for flour, yeast, packaging, and finished goods, across multiple locations, based on expiration dates and stock levels.

Calculate detailed costing at recipe, batch, and product levels to track margins and support profitable decision-making for bakery SKUs.

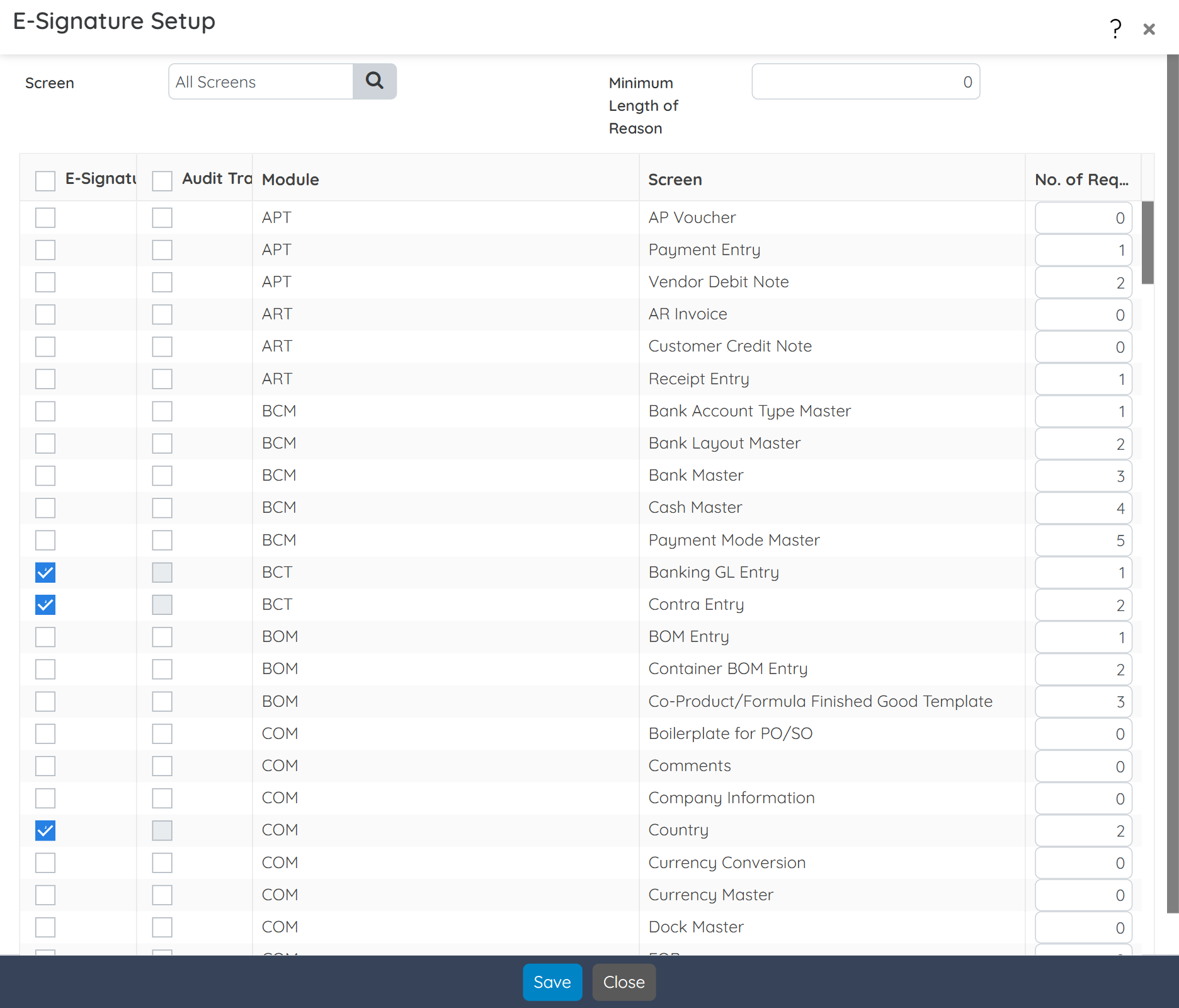

Ensure end-to-end compliance with FSMA, HACCP, and SQF requirements with proper documentation, monitoring of critical control points, and other regulatory reporting covering every stage of bakery operations from mixing to packing.

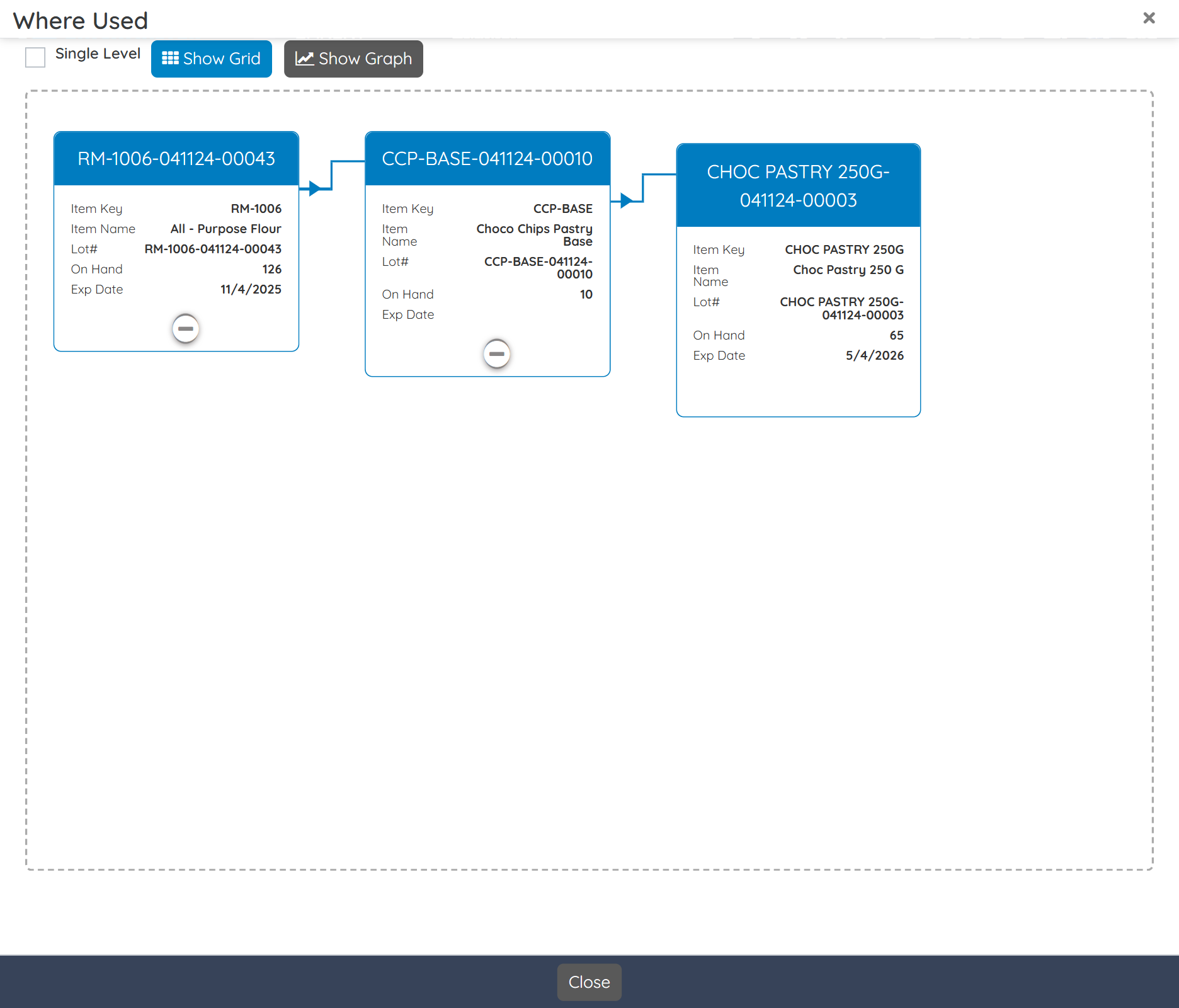

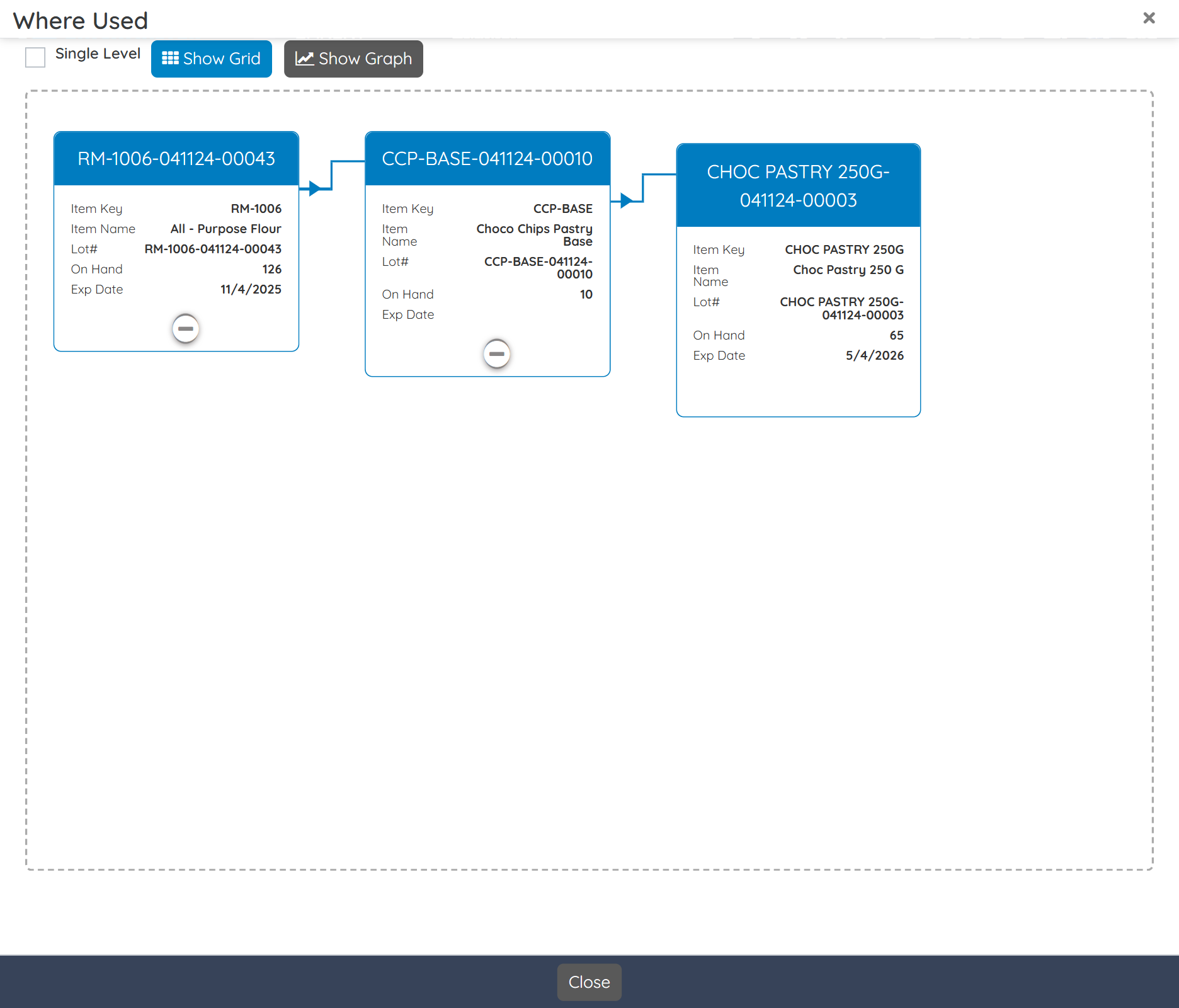

Track and trace every lot from flour, yeast, dough, finished goods to the entire supply chain to support backward and forward traceability along with full compliance with FDA’s Food Traceability List (FTL).

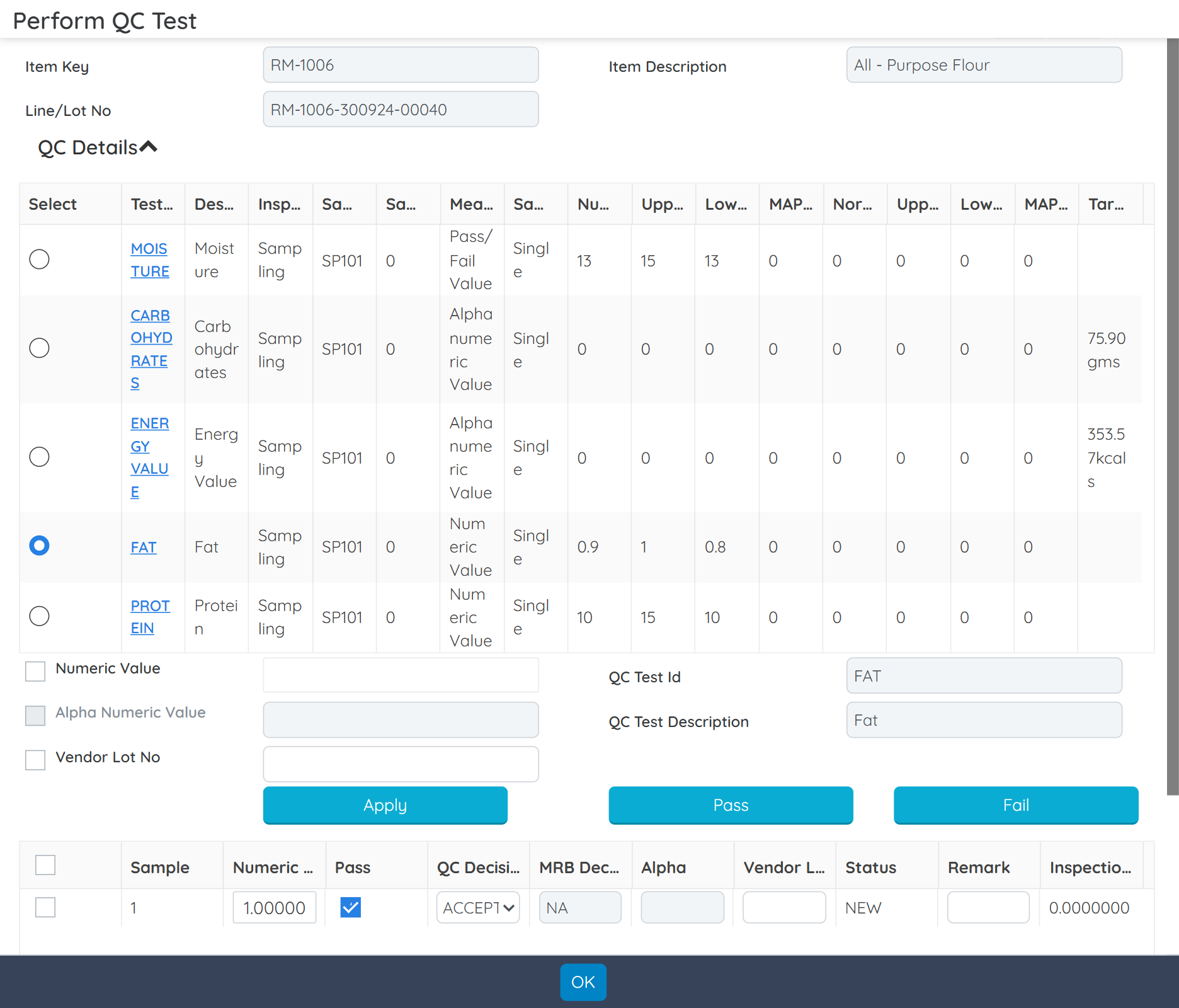

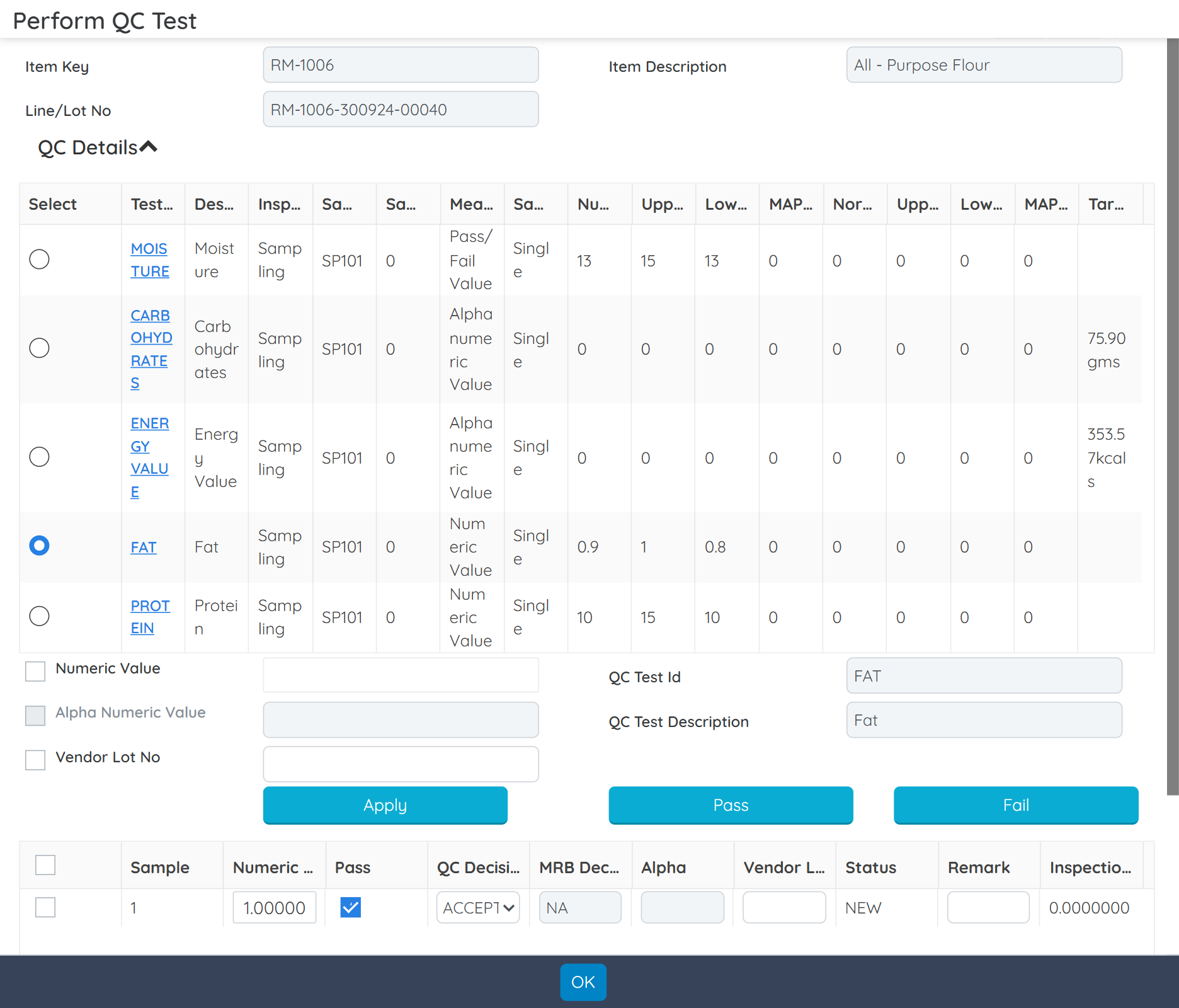

Maintain high product standards with in-process QC tests, inspection plans, and checklists across each production stage. It also helps in auto-generating Certificates of Analysis (COAs) to validate quality before final dispatch.

Learn how our bakery ERP software supports your unique manufacturing needs, from product development and production to quality, costing, and compliance.

Why Leading Bakery Manufacturers Switched to BatchMaster ERP?

Seamless Integration with Leading Financial Systems

Why Do Bakery Manufacturers Choose BatchMaster?

Our Bakery Management Software is purpose-built to address the unique challenges bakery manufacturers face, such as managing short shelf-life products, controlling precise fermentation, mitigating allergen risks, and handling high-volume batch production. Our industry-specific ERP empowers bakeries to scale operations, stay compliant, reduce waste, and maintain consistent product quality. Backed by bakery-specific features and dedicated in-house implementation experts, BatchMaster becomes more than just software, but a strategic partner in growth.

Explore the ERP That Understands Bakery Operations

BatchMaster Bakery ERP Resources

BatchMaster ERP for Bakery ERP: FAQs