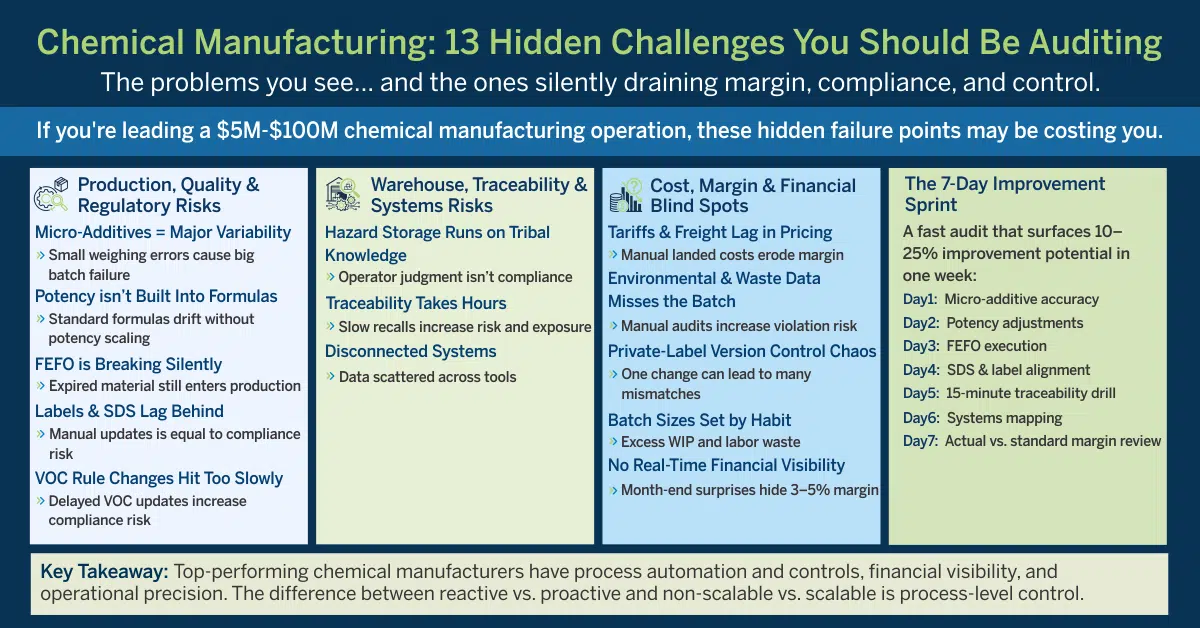

The Problems You See… And the Ones You Don’t

Chemical manufacturing rarely fails because of “bad chemistry”.

It fails because of invisible operational dependencies, micro-variability, tribal knowledge, and outdated systems that can’t keep up with modern manufacturing complexity.

If you’re a CEO, COO, CFO, or Ops leader at a $5M–$100M chemical manufacturing organization, you probably already know the obvious challenges:

- Potency swings

- Tight VOC limits

- Hazard labeling headaches

- Cost volatility

- Batch variability

- Traceability and recall pressure

But after working in this industry for three decades, here’s what we’ve learned:

Most chemical manufacturers don’t struggle because of the challenges themselves but because of the hidden failure modes behind those challenges.

This Playbook breaks down the 13 operational failure modes we see most often, why they happen, and how top-performing plants prevent them.

These are the patterns that separate a “reactive” plant from a “controlled and scalable” plant.

Let’s get into it.

Failure Mode #1: Micro-Additives Are Causing 80% of Your Batch Variability

Most plants measure big ingredients carefully. But the 1–5 gram additives?

While tools like Excel and spreadsheets will always have a place in daily operations, they were never designed to manage:

Often weighed on aging scales or eyeballed based on “how John normally does it”.

Why this is dangerous:

A 2g deviation on a 1,500L coating batch can shift viscosity, wetting, or adhesion enough to trigger rework.

What the smartest plants do:

- Set tolerance bands for micro-additives

- Integrate scales directly into batch instructions

- Block production if an additive is out of spec

- Use automated prompts for micro-dosing

Quick win:

Audit your last 20 deviations and count how many were caused by additives under 50g.

(The number is almost always surprising.)

Failure Mode #2: You’re Not Accounting for Potency — You’re Guessing

Lot-to-lot variability is normal, especially for pigments, catalysts, surfactants, and titanium dioxide.

Most plants track potency… somewhere. (Maybe in QC… or on a clipboard… or in an email.)

Why this hurts:

If potency isn’t built into formula scaling, your “standard formula” is only standard on paper.

What high-performance plants do:

- Capture potency at receiving

- Automatically scale formulas

- Enforce QC-based potency validation

- Recalculate WIP and finished cost in real time

Quick win:

Pull the last 10 potency adjustments your QC team made. Are those adjustments actually feeding into production? If not, that’s a silent cost leak.

Failure Mode #3: FEFO Isn’t Working the Way You Think It Is

Every plant claims they’re FEFO.

But reality often looks like:

- Retest dates on spreadsheets

- Drums staged based on convenience

- Operators grabbing whatever is closest

- No system preventing expired material usage

Why this matters:

Just one expired crosslinker or stabilizer can tank a batch, or worse, a full product line.

Smart plants:

- Enforce FEFO rules at the system level

- Block expired/retest-required lots automatically

- Use mobile devices to guide picks

- Track shelf-life and retest intervals by material type

Quick win:

Audit your last 8-12 months of deviations and see how many can be traced to expired or “should’ve-been-retested” drums?

Failure Mode #4: Your Labels and SDS Updates Are Always One Step Behind

This is the silent compliance killer.

Most plants manage labels and SDS manually, which means:

- GHS classifications drift

- Reformulations don’t trigger label updates

- Old pictograms sneak onto new shipments

- Changes in hazard categories don’t sync across packaging formats

High-performing plants do this instead:

- Tie labels to formula versions

- Automatically regenerate SDS whenever a formula changes

- Lock label templates to regulatory rules

- Trigger alerts when any component’s classification changes

Quick win:

Check 5 of your top SKUs. Does the GHS classification on the label match the SDS version used in production? (You might be surprised.)

Failure Mode #5: You Respond to VOC Rule Changes Too Slowly

VOC regulations in the U.S., Canada, EU are not suggestions.

But many midsize plants are still using manual processes to:

- Identify impacted SKUs

- Reformulate

- Update specs

- Update labels

- Train production

- Notify customers

When the Canadian federal VOC regulation changes hit, many plants lost weeks, even months to manual coordination.

Smart plants:

- Link VOC values directly to formulas

- Run “What products exceed the new limit?” reports instantly

- Automate version-controlled formula updates

- Sync changes across QC, production, labels, SDS, and BOM

Quick win:

Ask your R&D team:

“How long would it take us to identify every SKU over a new VOC limit?”

If the answer is longer than 30 minutes, that’s a red flag.

Failure Mode #6: Your Hazard Storage Depends on Tribal Knowledge

If your forklift operator is your hazard segregation strategy… you have a problem.

Typical symptoms:

- Flammables staged near oxidizers

- Corrosives stored outside temperature tolerance

- Operators using “instinct” instead of bin rules

- Inconsistent staging between shifts

Smart plants:

- Use hazard-based bin assignments

- Enforce storage rules digitally

- Guide operators via handheld devices

- Restrict incompatible materials automatically

Quick win:

Pick one zone in your warehouse and map where materials should be stored vs. where they actually are.

Failure Mode #7: Traceability Takes Hours, Not Seconds

This is one of the most expensive hidden failure modes.

If a customer complains about a batch, how long until you can answer:

- Which lots went into this product?

- Which intermediates did they feed into?

- Which customers received affected batches?

If the answer is more than 60 seconds, your traceability is costing you money, time, and customer trust.

Smart plants:

- Maintain bi-directional traceability

- Link raw-material lots to intermediates and finished goods

- Run recall reports instantly

- Connect QC results directly to batch genealogy

Quick win:

Run a mock recall on your highest-volume SKU.

How long until you have full genealogy?

This failure mode is invisible until it’s catastrophic.

Failure Mode #8: Disconnected Systems Create “Black-Hole Reporting”

Symptoms:

- Purchasing in one system

- QC on spreadsheets

- Production in a homegrown tool

- Finance in QuickBooks

- Management reports built by hand

Some manufacturers even refer to their operations as a “black hole of data” before modernizing their systems.

Smart plants:

- Consolidate purchasing, production, QC, compliance & finance

- Eliminate manual merging

- Use unified dashboards

- Standardize reporting across all departments

Quick win:

List every system where you currently store production or quality data.

If the list is more than 3 systems long, reporting is costing you days per month.

Failure Mode #9: Tariff & Freight Changes Don’t Flow Into Pricing Fast Enough

Chemical manufacturers have been hammered by:

- Chinese chemical tariffs

- Shifting freight container rates

- Sudden duty changes

- Import/export disruptions

Most midsize plants update costing manually which means pricing lags behind costs.

Smart plants:

- Update landed costs in real time

- Recalculate product margins automatically

- Push updated costs into price lists

- Give leadership visibility into margin erosion as it happens

Quick win:

Ask your costing team:

“How many spreadsheets do we maintain just for tariffs and landed costs?”

Your cost volatility exposure is hiding in that answer.

Failure Mode #10: Environmental & Waste Data Isn’t Being Captured at the Batch Level

EPA, OSHA, state regulators, and customers want increasing transparency.

But most plants collect waste and emissions data manually, inconsistent, or after the fact.

That’s how even major players like DuPont ended up with penalties due to gaps in hazardous waste documentation.

Smart plants:

- Capture emissions and waste at batch level

- Use QC tests for environmental parameters

- Maintain complete audit trails

- Tie waste streams to formulas & batches

Quick win:

Review your last environmental audit.

What data was hard to find? That’s where the risk hides.

Failure Mode #11: Private-Label Formulations Become Version-Control Nightmares

One formula change; 14 private label variants; multiple labels; dozens of specs.

Manual version control = chaos, rework, and risk.

Smart plants:

- Version formulas and specs together

- Compare differences side-by-side

- Push updates automatically to labels, SDS, QC & production

- Keep customer-specific requirements fully synchronized

Quick win:

Pick one private-label product and map all its dependencies (labels, specs, packaging, intermediates).

You’ll see the spiderweb instantly.

Failure Mode #12: Batch Sizes Are Set by Habit — Not by Cost or Demand

Many plants run “safe” batch sizes based on history, not economics.

This leads to:

- Excess WIP

- Expired materials

- High changeover costs

- Excess labor

- High carrying costs

Smart plants:

- Use demand-driven planning

- Optimize batch sizes dynamically

- Run cost simulations

- Adjust based on seasonality, customer mix, and labor capacity

Quick win:

Take your 3 highest-volume SKUs and recalculate batch sizes using actual demand + actual cost drivers.

You’ll find easy margin.

Failure Mode #13: You Don’t Have Real-Time Financial Visibility — Only Month-End Surprises

Most chemical plants run operations daily but financials weekly or monthly.

That gap hides massive profitability leaks.

Typical symptoms:

- No real-time batch costing

- Standard costs outdated for months

- Tariff/freight changes not reflected in pricing

- Potency-adjusted inventory not calculated

- No SKU or customer-level profitability

- Finance & Operations reporting different numbers

Why this matters:

If costing and financials don’t update in real time:

- Margins erode silently

- “Profitable” SKUs turn out unprofitable

- Sales quotes outdated prices

- Leadership makes decisions on stale data

- Price lists lag behind cost changes

A 3–5% margin swing often comes from missing landed cost updates alone.

What smart plants do:

- Connect production, inventory, costing & financials

- Update actual vs. standard cost automatically

- Track SKU & customer profitability

- Roll up landed cost changes instantly

- Tie formula changes to margin impact

- Use margin dashboards daily, not monthly

Quick win:

Ask finance + operations:

“What was the actual margin of our top 10 SKUs last month?”

If answers differ or require spreadsheets that means financial visibility is a hidden failure mode.

The 7-Day Improvement Sprint

A mini playbook your team can implement without any software change.

Day 1: Audit micro-additive accuracy

Day 2: Review potency adjustments

Day 3: Validate FEFO execution

Day 4: Cross-check 5 SKUs for SDS/label mismatch

Day 5: Run a 15-minute traceability drill

Day 6: Map all systems used for production/QC

Day 7: Compare actual vs. standard margin for your top 10 SKUs (Finance + Ops)

This revised sprint surfaces hidden losses in accuracy, compliance, traceability, systems, and financial visibility, revealing 10–25% improvement opportunities in just one week.