Mobile Warehouse (WMS) and Production (MES) Software

Explore BatchMaster's Mobile Warehousing and Production Features

INCREASE PRODUCTIVITY AND THROUGHPUT, WHILE REDUCING ERRORS

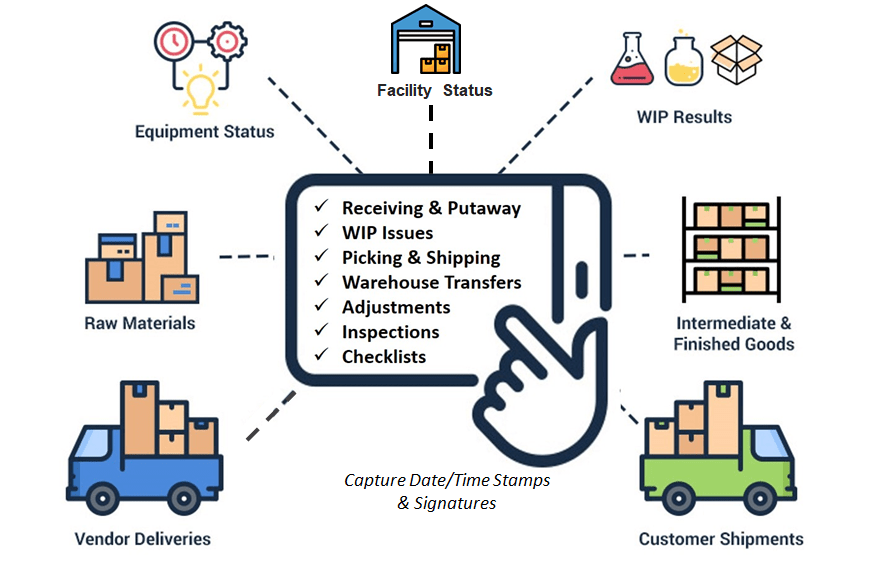

Warehouse Management software allows plant floor users to perform receiving, putaway, pick, pack and shipping tasks within their warehouse locations, in addition to quality control, production, inventory adjustment and movement tasks.

To reduce rework and errors, the capture and validation of critical data captured via mobile warehouse transactions can be mandated by the system, before allowing the user to proceed to their next task. Mobile transactions update operational records in real time, so that all users and business processes are accessing the most accurate and up to date data.

This browser based application runs on a wide range of mobile platforms, including smart phones and tablets, as well as RF data collection devices, without the need for any third-party interfaces.

MOBILE WAREHOUSING AND PRODUCTION FEATURES THAT WILL CHANGE THE WAY YOU WORK

productivity and facility throughput, and reduces data entry errors.

- Confirm PO receipts.

- Check inbound trailer conditions and documentation.

- Build licensed or non-licensed pallets of single item or multi items for putaway.

- Control batch job releases and completions.

- Pull raw materials into WIP and return balances to storage.

- Pick, pack and ship finished goods for customer shipments.

- Maintain historical records of key mobile warehouse transactions for audit purposes (e.g. lot traceability reports).

- Capture QC information of inbound raw materials.

- Check physical condition of on-hand inventory.

- Validate inventory location, license ID, lot number, quantity and other characteristics.

- Capture QC information during WIP.

- Capture QC information of finished goods.

- Generate required labels and rep

CONTACT US / REQUEST A DEMO

DOCUMENTS

BatchMaster ERP Mobile

Read about the key manufacturing and warehousing tasks that can be performed using smart devices