Quality Control Software

ERP FOR QUALITY CONTROL TO ENSURE PRODUCT CONSISTENCY

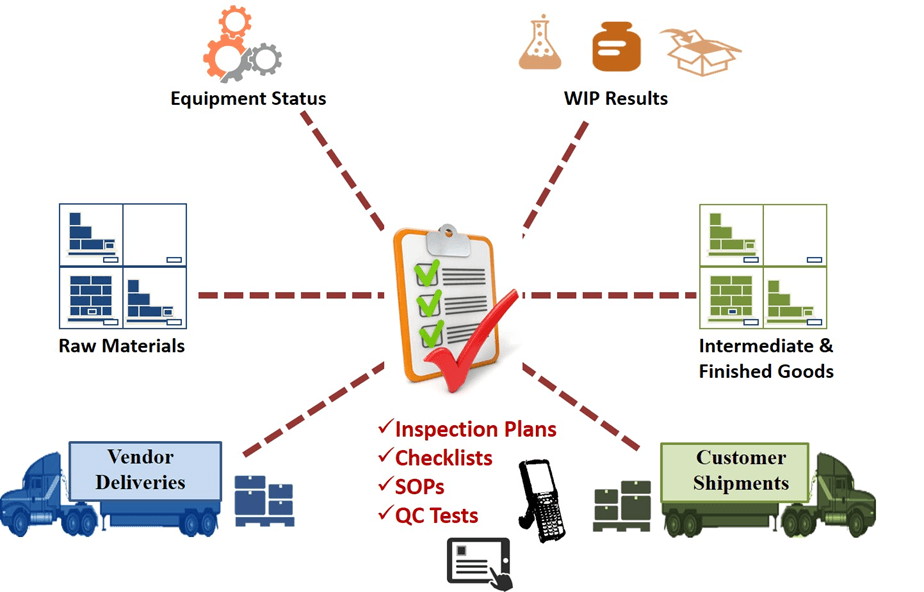

Quality capabilities are found throughout the production and distribution processes to ensure that delivered raw materials to shipped finished goods all meet your corporate and customer’s strict quality standards.

Quality managers can establish a library of inspection plans, checklists and QC tests. Receiving personnel will then capture QC tests of delivered goods and disposition the goods based upon the QC results. Warehouse staff can perform stability checks, physical and cycle counts of inventory in stock. And in WIP, line personnel will capture QC test results which may lead to production to rework the product in WIP by adjusting certain batch job formula values and equipment settings.

QUALITY CONTROL SOFTWARE THAT WILL CHANGE THE WAY YOU WORK

QC and QA improves manufacturing processes, corrects out of tolerance equipment, reduces waste, and most importantly, minimizes customer chargebacks.

- Define inspection plans and checklists

- Define QC tests with accepted values, tolerance values, sample and recount values

- Capture QC tests via mobile devices

- Assign inventory with user defined QC statuses

- Disposition inventory based upon QC status

- Generate customized Certificates of Analysis

- Embed QC tests and special manufacturing instructions within specifications

- Analyze QC historic results

- Manage adverse reporting, deviation and non conformance situations

CONTACT US / REQUEST A DEMO

Let’s see if BatchMaster Software has the right software solution for your needs. Contact Us to share something about your operations and software needs with our consultants or Request A Demo of one of our software applications.

VIDEO

Food

Food processors – Learn how to setup a comprehensive quality management program that ensures the continuous flow of high quality products as you scale up production

Chemical

Chem processors – Learn how to setup a comprehensive quality management program that ensures the continuous flow of high quality products as you scale up production

Nutra & Pharma

Nutra & Pharma processors – Learn how to setup a comprehensive quality management program that ensures the continuous flow of high quality products as you scale up production