Batch Manufacturing ERP Software

Streamline and Scale Up Batch Production with BatchMaster

PRODUCTION PROCESS SOFTWARE TO STREAMLINE OPERATIONS

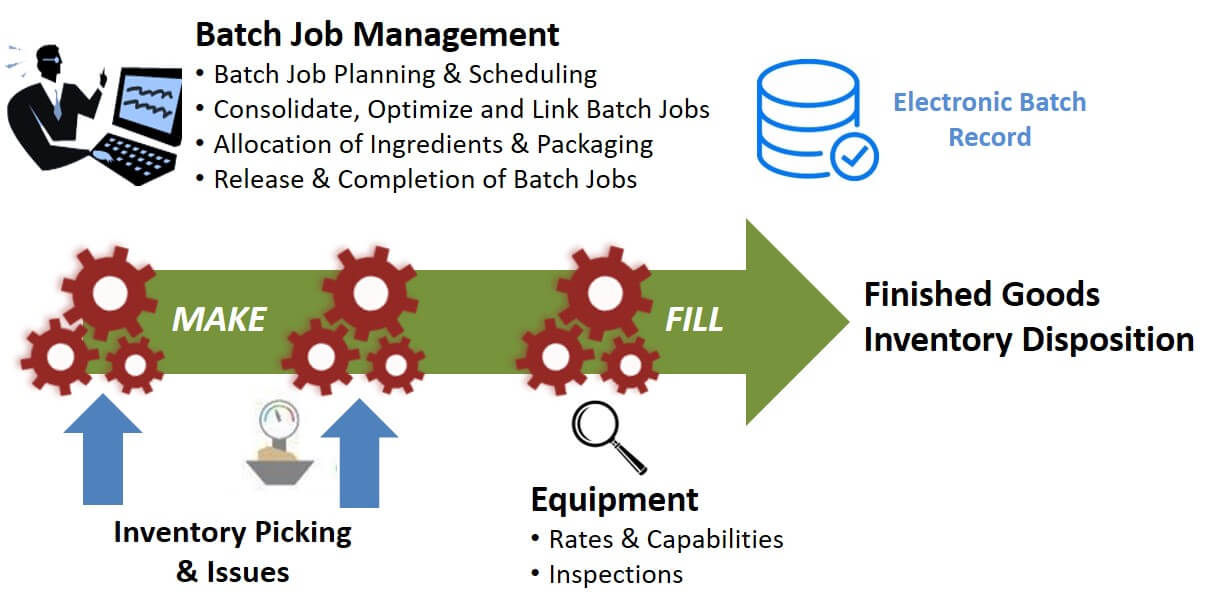

BatchMaster’s Production Module manages all the mix, blend, fill, assemble, and other manufacturing processes required to produce one’s intermediates and finished goods, including co-products and by-products. In addition to supporting make-to-stock operations, custom blenders, private label, toll and contract manufacturers can take advantage of our application’s make-to-order features.

From inventory appropriation to finished goods completion, all production and quality related transactions are captured and reported, including actual inventory usage, labor costs, and yields, during all steps in the batch manufacturing process

BATCH PRODUCTION SOFTWARE THAT WILL CHANGE

THE WAY YOU WORK

BatchMaster’s production process software allows you to quickly and easily streamline

production through the use of these transactions:

production through the use of these transactions:

- Dynamically adjust batch formulas and packaging bill of materials

- Link dependent batch jobs together

- Dynamically size and schedule batch jobs

- Manage equipment and resource availability and capacities

- Assign equipment and labor to batch jobs

- Reserve inventory for specific batch job

- Prioritize and expedite batch jobs

- Rework intermediates and finished goods during production

- Auto generate lot numbers for intermediates and finished goods

- Automatically backflush inventory

CONTACT US / REQUEST A DEMO

Let’s see if BatchMaster Software has the right software solution for your needs. Contact Us to share something about your operations and software needs with our consultants or Request A Demo of one of our software applications.