Food Manufacturing ERP Software

Food Manufacturing ERP Software

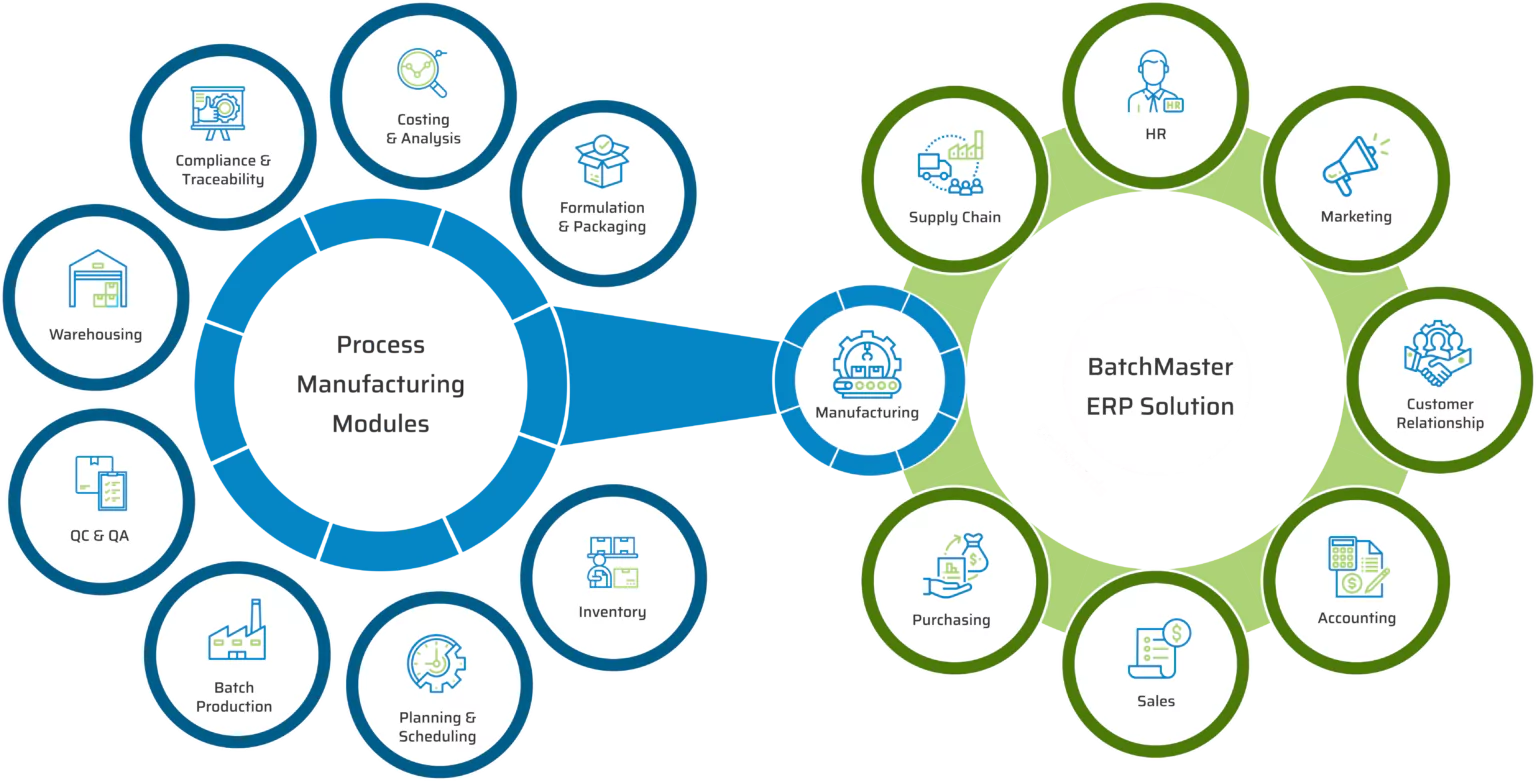

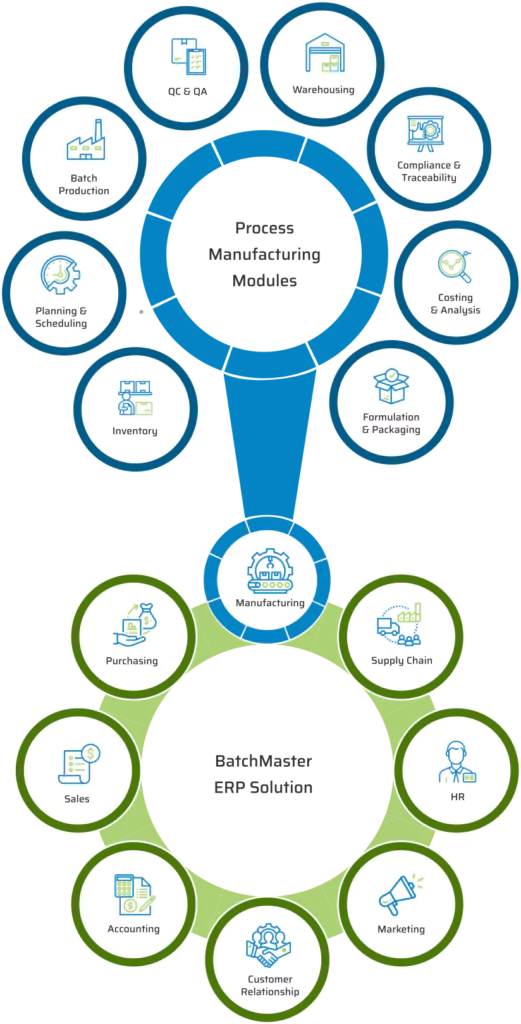

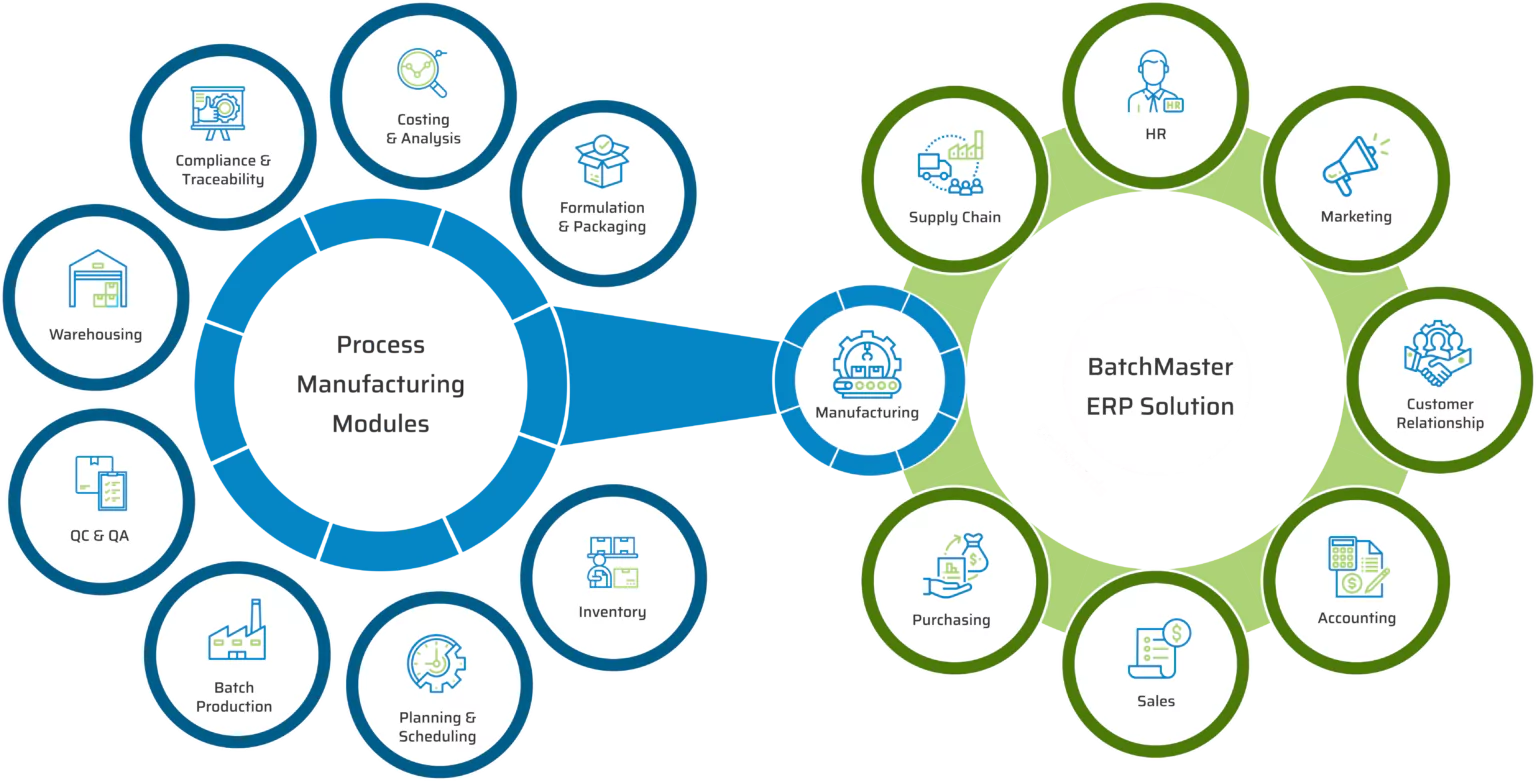

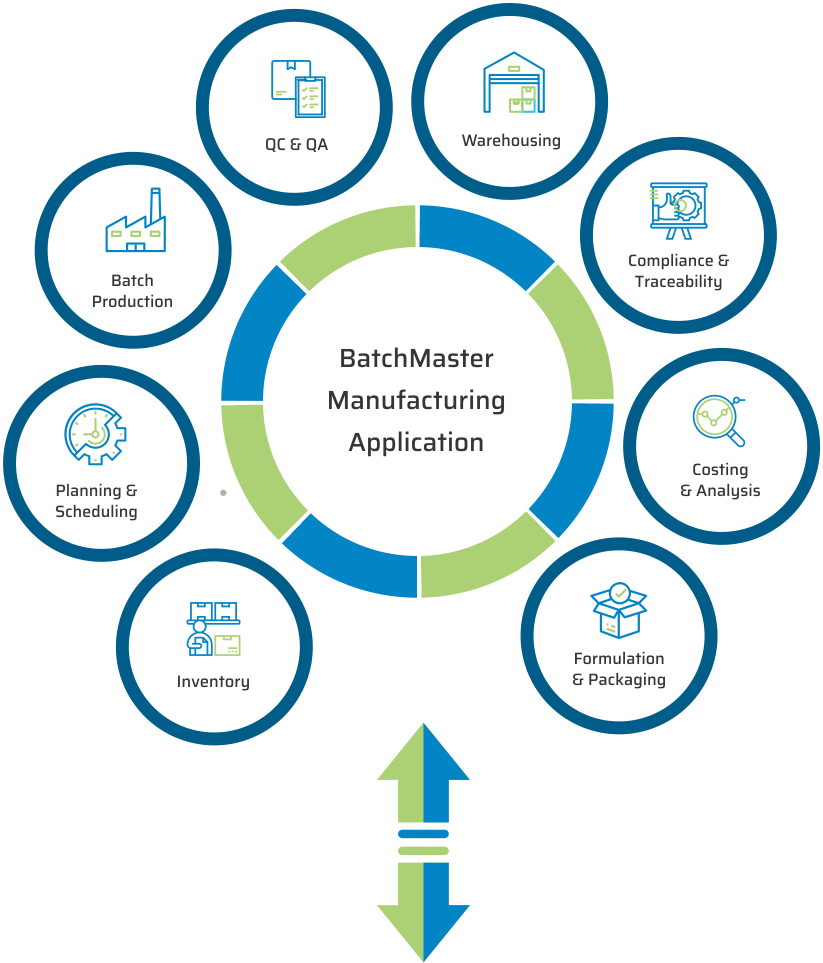

BatchMaster ERP is tailor-made for food and beverage companies, from product development, planning, scheduling, and production to inventory, quality control, compliance, etc.

BatchMaster assists food producers and distributors in automating and streamlining operations, lowering costs, and improving food safety, as well as achieving business success quicker.

Best-in-Class ERP for Food and Beverage Manufacturing Industry Verticals

Overcome your unique business challenges with tailored ERP solution designed specifically for your food and beverage industry segments.

Bakeries & Snack

Beverages

Dairy

Dressings & Sauces

Spices &

Seasonings

Flavors &

Additives

Frozen &

Packed Foods

Confectionery &

Chocolate

Industry-leading Capabilities Designed for Food Industry Manufacturers

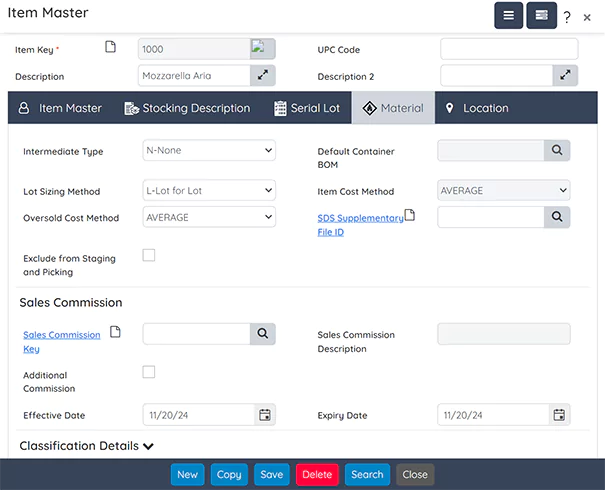

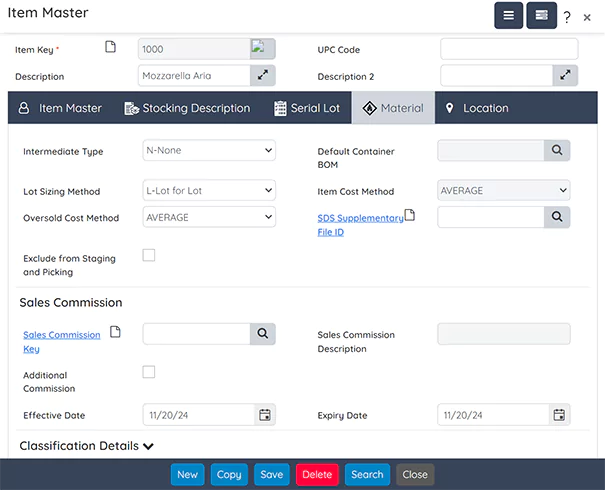

Efficient inventory management ensures seamless tracking and movement of ingredients, packaging, and finished goods, while monitoring quality control statuses, weights, and plant locations.

Key features include:

- Attribute Management: Maintain records for allergens, safety, certifications, and industry-specific documents.

- Smart Allocation: Allocate inventory based on expiry dates and quality status.

- Batch Adjustments: Dynamically adjust batch jobs according to inventory characteristics.

- Mobile Warehousing: Execute warehousing tasks efficiently using mobile devices.

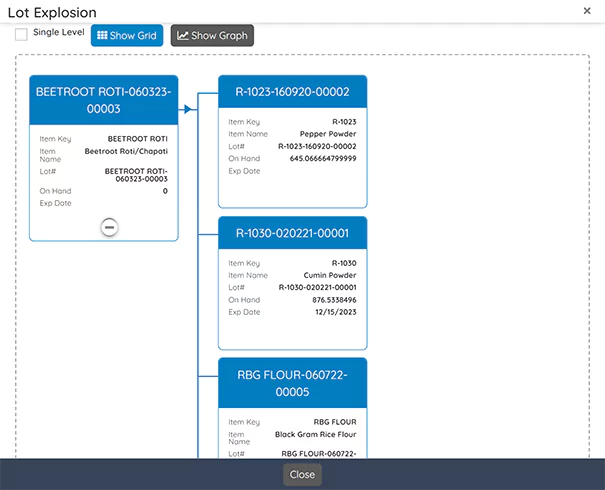

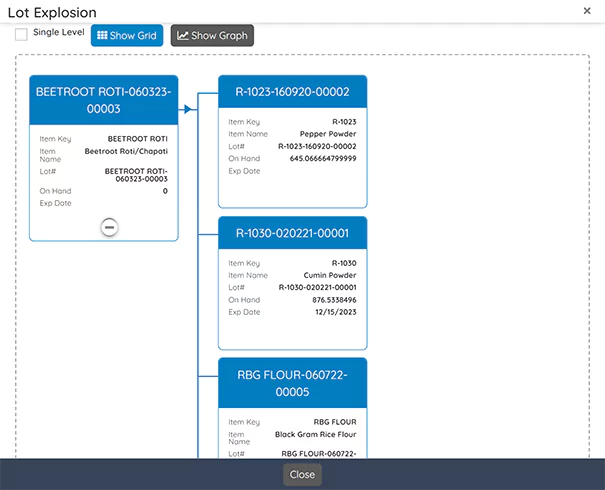

Our lot-controlled inventory system maintains a complete lineage from receiving to shipping, covering raw materials and finished products.

Key features include:

- Automatic Lot Numbering: Assign lot numbers automatically during receiving and production.

- Lifecycle Tracking: Capture and validate lot numbers at every stage of production.

- Quick Searches: Perform bi-directional searches using an intuitive graphical tool.

- Recall Management: Generate barcoded labels (e.g., product labels, pallet licenses) to further streamline operations.

Integrate quality control and assurance throughout all processes, ensuring product safety and compliance.

Key features include:

- QC Testing: Set up quality control tests with specified tolerance and sample values.

- Inspection Plans: Execute comprehensive inspection plans and checklists.

- Documentation: Generate Certificates of Analysis (COA) and manage production deviations.

- Issue Management: Address customer complaints and nonconformance situations effectively.

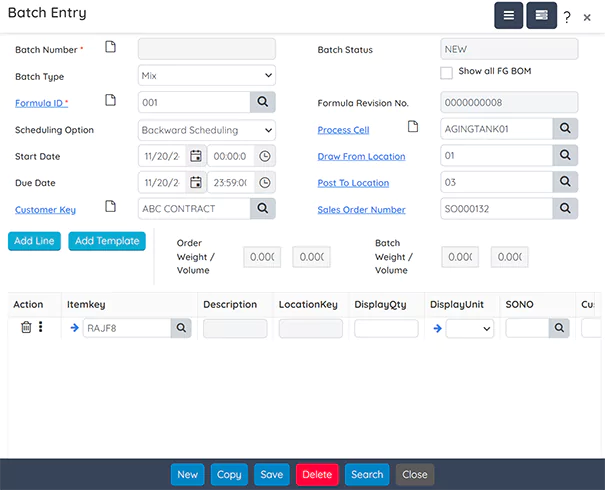

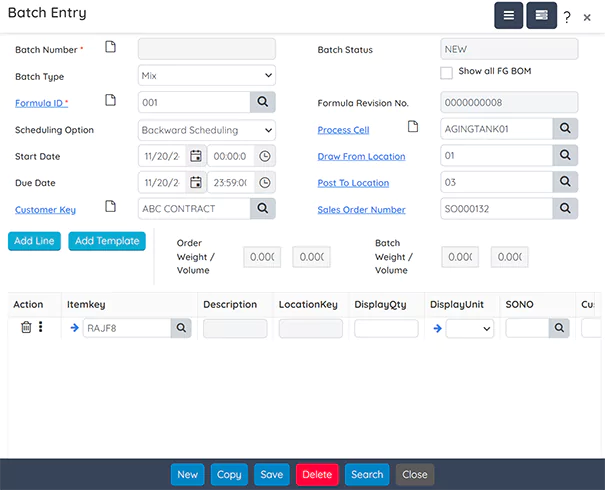

Optimize production processes for intermediates and finished goods, including co-products and by-products.

Key features include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

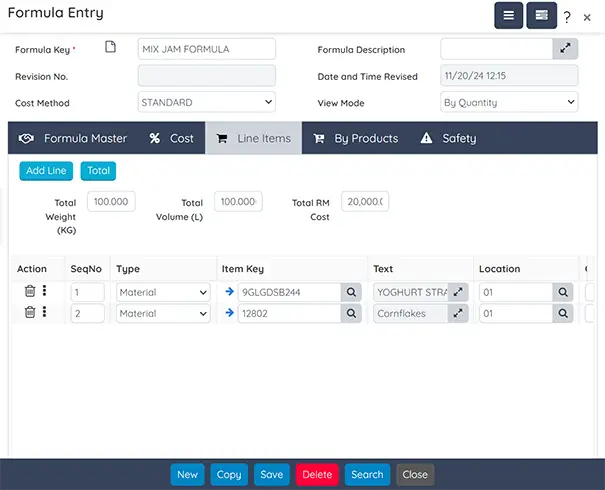

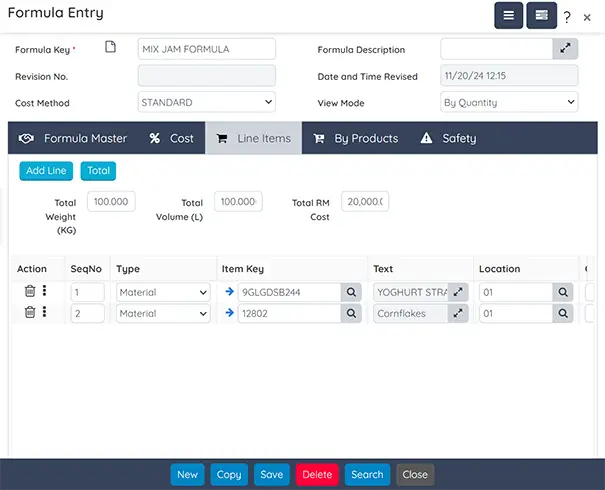

Facilitate the management of product specifications across multiple versions and formulations.

Key features include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

Ensure adherence to federal and industry-specific regulations throughout every process.

Key features include:

- Real-Time Alerts: Notify formulators when specifications exceed established levels.

- Data Capture: Mandate the collection of item, user, and location data for compliance (CFR 11).

- Audit Trail Maintenance: Maintain transactional history for auditor reporting, including Master Batch Records.

- Label Generation: Automatically generate required product and safety labels and documents.

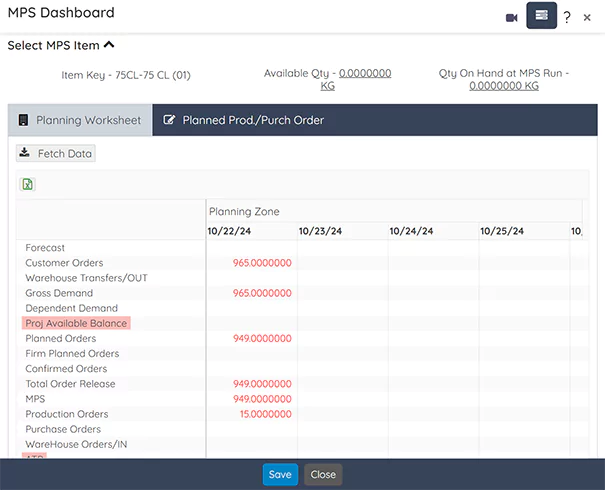

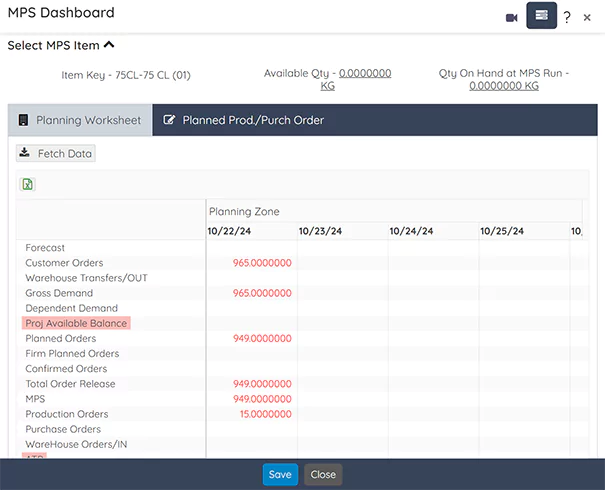

Optimize production and procurement processes to meet demand effectively.

Key features include:

- Comprehensive Planning: Establish short, medium, and long-range planning periods.

- Facility Management: Plan production by facility or across multiple locations.

- Supply and Demand Consolidation: Streamline supply and demand management across facilities.

- What-If Analysis: Perform scenario analysis while planning production schedules.

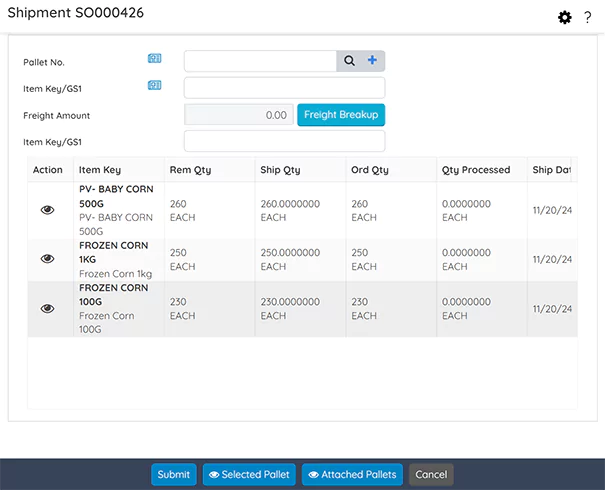

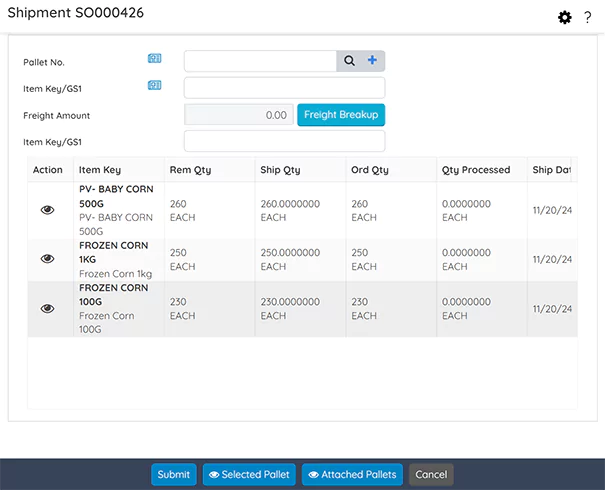

Empower plant floor users to efficiently manage receiving, putaway, picking, packing, and shipping tasks.

Key features include:

- Batch Job QC Test: Capture QC information for inbound raw materials and WIP.

- Equipment Checklists and Inspections: Check the physical condition of on-hand inventory.

- Validate inventory location: license ID, lot number, and quantity.

- Generate required labels and reports: Generate barcoded labels (e.g. product labels and pallet licenses) to further streamline operations.

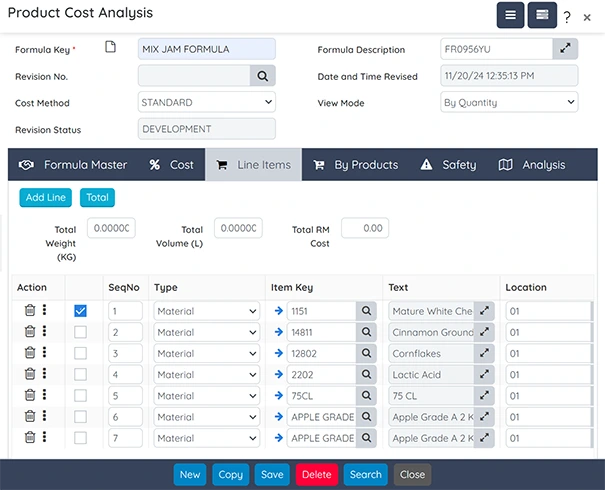

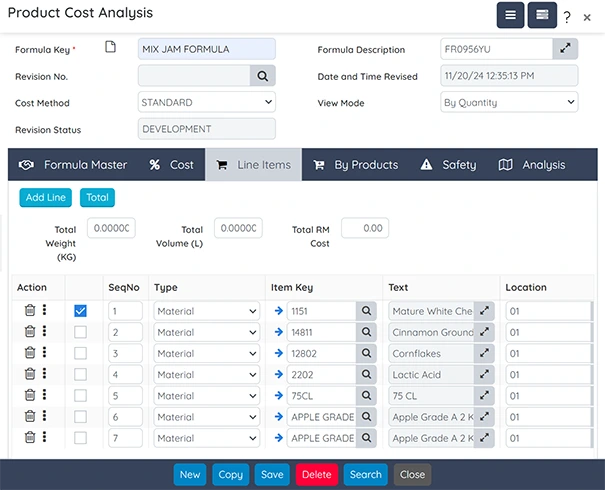

Balance consumer preferences with cost-effectiveness and production efficiency.

Key features include:

- Comprehensive cost analysis of specifications

- Comparing costs: associated with ingredients, labor, consumables, and additional shipping or miscellaneous expenses

- Validate inventory location: license ID, lot number, and quantity.

- Generate required labels and reports: Generate barcoded labels (e.g. product labels and pallet licenses) to further streamline operations.

Key features include:

- Attribute Management: Maintain records for allergens, safety, certifications, and industry-specific documents.

- Smart Allocation: Allocate inventory based on expiry dates and quality status.

- Batch Adjustments: Dynamically adjust batch jobs according to inventory characteristics.

- Mobile Warehousing: Execute warehousing tasks efficiently using mobile devices.

Key features include:

- Automatic Lot Numbering: Assign lot numbers automatically during receiving and production.

- Lifecycle Tracking: Capture and validate lot numbers at every stage of production.

- Quick Searches: Perform bi-directional searches using an intuitive graphical tool.

- Recall Management: Generate barcoded labels (e.g., product labels, pallet licenses) to further streamline operations.

Integrate quality control and assurance throughout all processes, ensuring product safety and compliance.

Key features include:

- QC Testing: Set up quality control tests with specified tolerance and sample values.

- Inspection Plans: Execute comprehensive inspection plans and checklists.

- Documentation: Generate Certificates of Analysis (COA) and manage production deviations.

- Issue Management: Address customer complaints and nonconformance situations effectively.

Key features include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

Facilitate the management of product specifications across multiple versions and formulations.

Key features include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

Ensure adherence to federal and industry-specific regulations throughout every process.

Key features include:

- Real-Time Alerts: Notify formulators when specifications exceed established levels.

- Data Capture: Mandate the collection of item, user, and location data for compliance (CFR 11).

- Audit Trail Maintenance: Maintain transactional history for auditor reporting, including Master Batch Records.

- Label Generation: Automatically generate required product and safety labels and documents.

Optimize production and procurement processes to meet demand effectively.

Key features include:

- Comprehensive Planning: Establish short, medium, and long-range planning periods.

- Facility Management: Plan production by facility or across multiple locations.

- Supply and Demand Consolidation: Streamline supply and demand management across facilities.

- What-If Analysis: Perform scenario analysis while planning production schedules.

Empower plant floor users to efficiently manage receiving, putaway, picking, packing, and shipping tasks.

Key features include:

- Batch Job QC Test: Capture QC information for inbound raw materials and WIP.

- Equipment Checklists and Inspections: Check the physical condition of on-hand inventory.

- Validate inventory location: license ID, lot number, and quantity.

- Generate required labels and reports: Generate barcoded labels (e.g. product labels and pallet licenses) to further streamline operations.

Balance consumer preferences with cost-effectiveness and production efficiency.

Key features include:

- Comprehensive cost analysis of specifications

- Comparing costs: associated with ingredients, labor, consumables, and additional shipping or miscellaneous expenses

- Validate inventory location: license ID, lot number, and quantity.

- Generate required labels and reports: Generate barcoded labels (e.g. product labels and pallet licenses) to further streamline operations.

A Modern, Cloud-Based ERP to Scale Up Your Food and Beverage Manufacturing Operations

BatchMaster empowers food and beverage processors with essential abilities to extend operations and increase efficiency. Our web-based ERP encompasses recipe and packaging control, costing, inventory, production, finance, and quality control—essentials for peak performance.

With planning and scheduling, BRC/SQL traceability and recall, FDA compliance, and warehousing on the move, BatchMaster offers real-time visibility and dynamic reporting for more comprehensive decisions and faster growth.

Why BatchMaster is the #1 Choice for Food Manufacturers?

Industry Expertise

With over two decades of experience, BatchMaster understands the unique challenges of the food and beverage sector.

Tailored Solutions

Our web-based ERP system is highly customizable to meet the specific business needs of formula and recipe-based batch manufacturers.

User-Friendly Interface

Modern, intuitive and easy-to-navigate dashboards and reporting tools make it simple for your team to leverage the power of our ERP system.

Scalability

BatchMaster scales with you as your business grows, accommodating increasing complexity and volume.

See What Food Industry Manufacturers Are Saying About BatchMaster

Diversified Foods and Seasonings, LLC

We evaluated nearly 15 ERP systems during our review period and selected BatchMaster Manufacturing because it could fill every need we had.

Cain Food Industries, Inc.

Cain Food Industries Inc. obtains improved lot traceability and function-rich formula module

Michou Deli

It's super simple to use the platform. Customer on boarding was simple and payback time for this platform is short. I couldn’t be any happier. Look no further than BatchMaster – their team is knowledgeable and professional

Metarom

We had a great experience with the BatchMaster implementation, and the support team. Everyone was very knowledgeable, and committed to helping us implement the system as fast as possible

Newly Weds Foods International

With success in China, we decided to implement BatchMaster in Australia, with business two and half times that in China. Again, being successful in Australia also, we implemented in Bangkok and the Philippines as well. BatchMaster seems to be doing the job very well for us!You Can Even Run Batch Master with Leading Financial Applications

Continue using your current financial application for your accounting needs while pairing it with a leading process manufacturing ERP designed specifically for the food and beverage industry.

About BatchMaster

BatchMaster is a leading provider of ERP solutions for process manufacturing, helping formula and recipe-based manufacturers worldwide streamline and scale their operations.

More than

2,000

Happy Customers

More than

2,500

Implementations

More than

40,000

Users

More than

30

Years of Experience

More than

500

Employees

More than

7

Offices

more than

40,000

Users

more than

30

Years of Experience

About BatchMaster

Specialized in Process Manufacturing ERP

Industry leader for over 3 decades

3,000+ customers

Services Offered – Process consulting, Integration, Support, Training, GMP/FDA validation