Leading Process Manufacturing ERP Software Built for Your Industry

Take a Product Tour

Best-in-Class ERP for Process Manufacturers

Bakeries & Snack

Chemical

Life Science & Pharma

Trusted by Leading Process Manufacturers Worldwide

Customer Success Spotlight

“Through implementation of BatchMaster ERP, we were able to realize significant efficiencies within our operation by streamlining sales, marketing, customer service, manufacturing, and quality control, leading to significant operational efficiencies.”

“The ability to integrate BatchMaster with QuickBooks was essential for us. We didn’t want to lose familiarity with QuickBooks, but we needed the advanced manufacturing capabilities of an industry-specific ERP. BatchMaster gave us the best of both worlds.”

The Right ERP Solution for Process Manufacturing Businesses

BatchMaster offers flexible ERP solutions tailored for growing small and medium-sized formula-based process manufacturers. These solutions empower manufacturers with essential manufacturing capabilities to scale operations and boost efficiency.

Choose the option that best fits your needs:

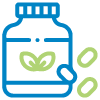

BatchMaster Cloud ERP

A comprehensive, cloud-based, end-to-end solution with a full suite of manufacturing functionalities. This web-based, easy-to-use, customizable, end-to-end ERP solution provides industry-specific capabilities within one centralized system to improve productivity, efficiency, and profitability.

BatchMaster

Manufacturing

Modules

BatchMaster

Backoffice

Modules

BatchMaster for SAP Business One

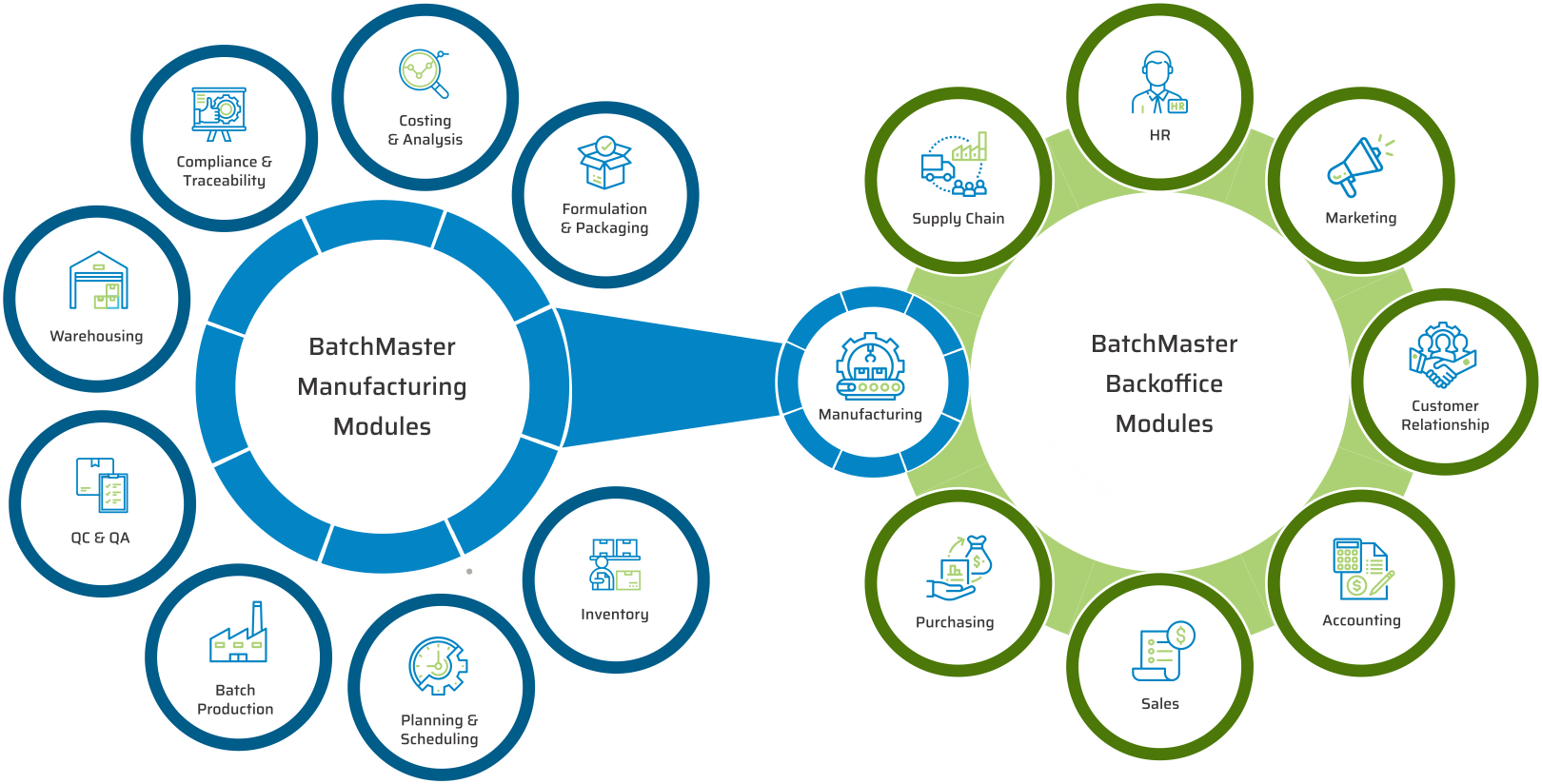

BatchMaster Integrations

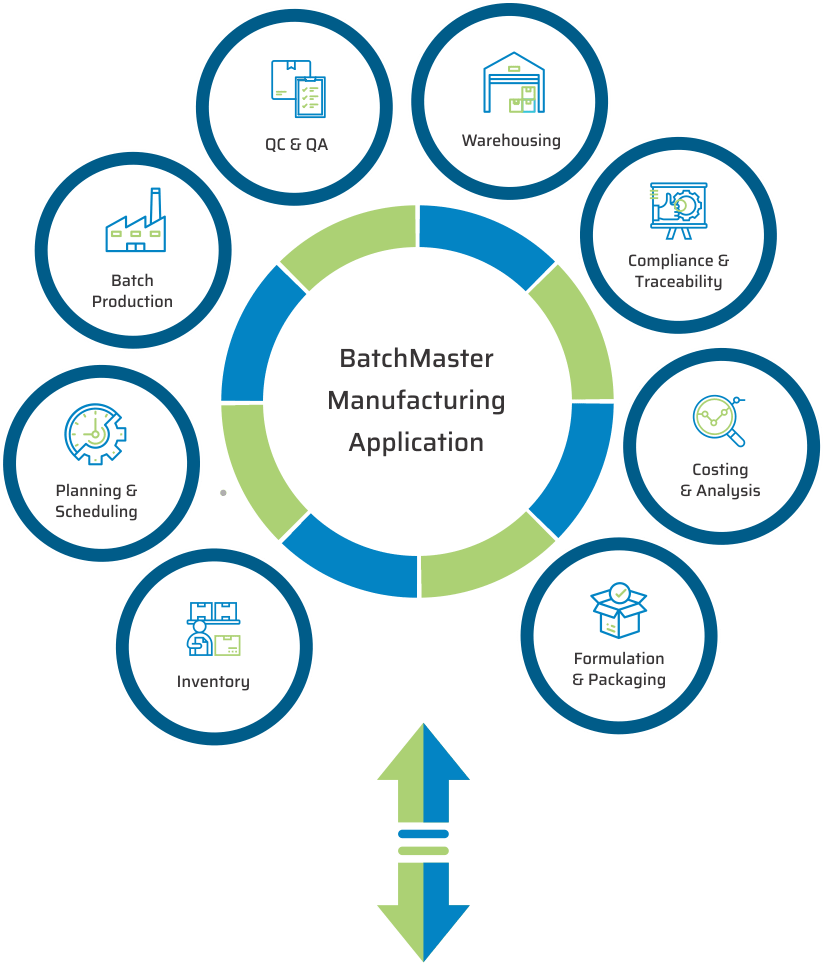

BatchMaster

Manufacturing

Application

Why is BatchMaster the #1 Choice for Process Manufacturers?

Industry Leader in Process Manufacturing

With over two decades of experience, BatchMaster understands the unique challenges of the process manufacturing sector.

Specialized Industry-Specific Solutions

Industry solutions for process manufacturing industries like Food & Beverage, Chemical, Pharmaceutical/Life Science, Nutraceutical, Personal Care and Cosmetic and other micro verticals.

User-Friendly Interface

Modern, intuitive and easy-to-navigate dashboards and reporting tools make it simple for your team to leverage the power of our ERP system.

Scalable to Support Growth

BatchMaster scales with you as your business grows, accommodating increasing complexity and volume.

Industry-leading Capabilities Designed for Process Manufacturers

- Inventory

- Traceability

- Quality Control

- Production

- Formulation

- Compliance

- Planning & Scheduling

- Mobile Warehousing

- Cost Analysis

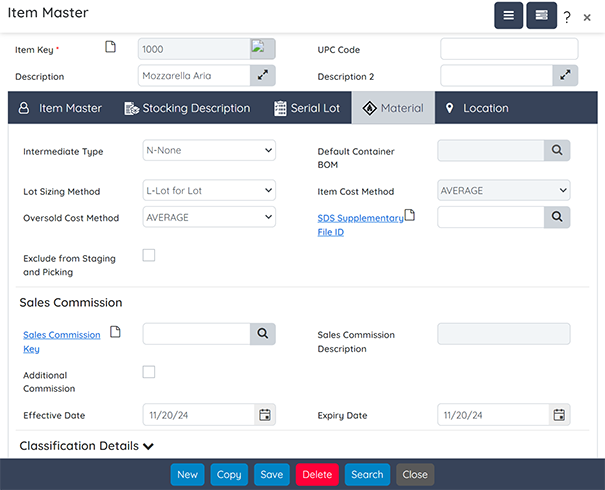

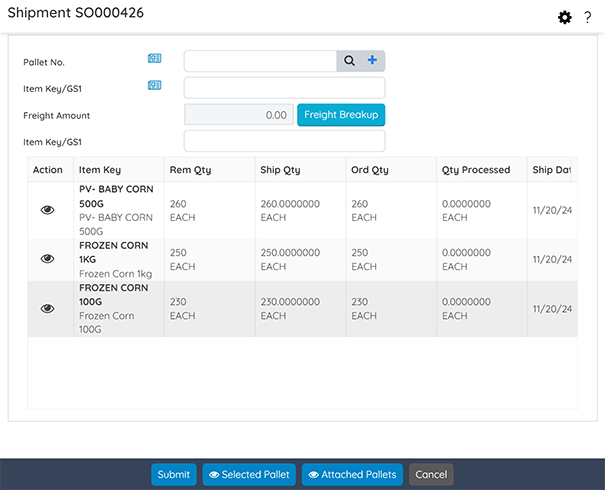

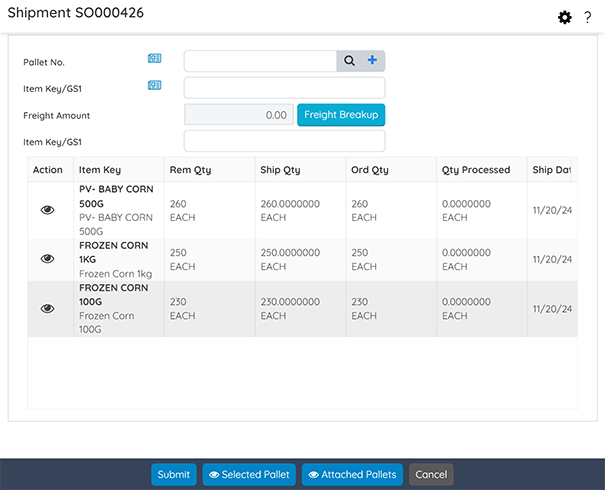

Inventory

Efficient inventory management ensures seamless tracking and movement of ingredients, packaging, and finished goods, while monitoring quality control statuses, weights, and plant locations.

Key features include:

- Attribute Management: Maintain records for allergens, safety, certifications, and industry-specific documents.

- Smart Allocation: Allocate inventory based on expiry dates and quality status.

- Batch Adjustments: Dynamically adjust batch jobs according to inventory characteristics.

- Mobile Warehousing: Execute warehousing tasks efficiently using mobile devices.

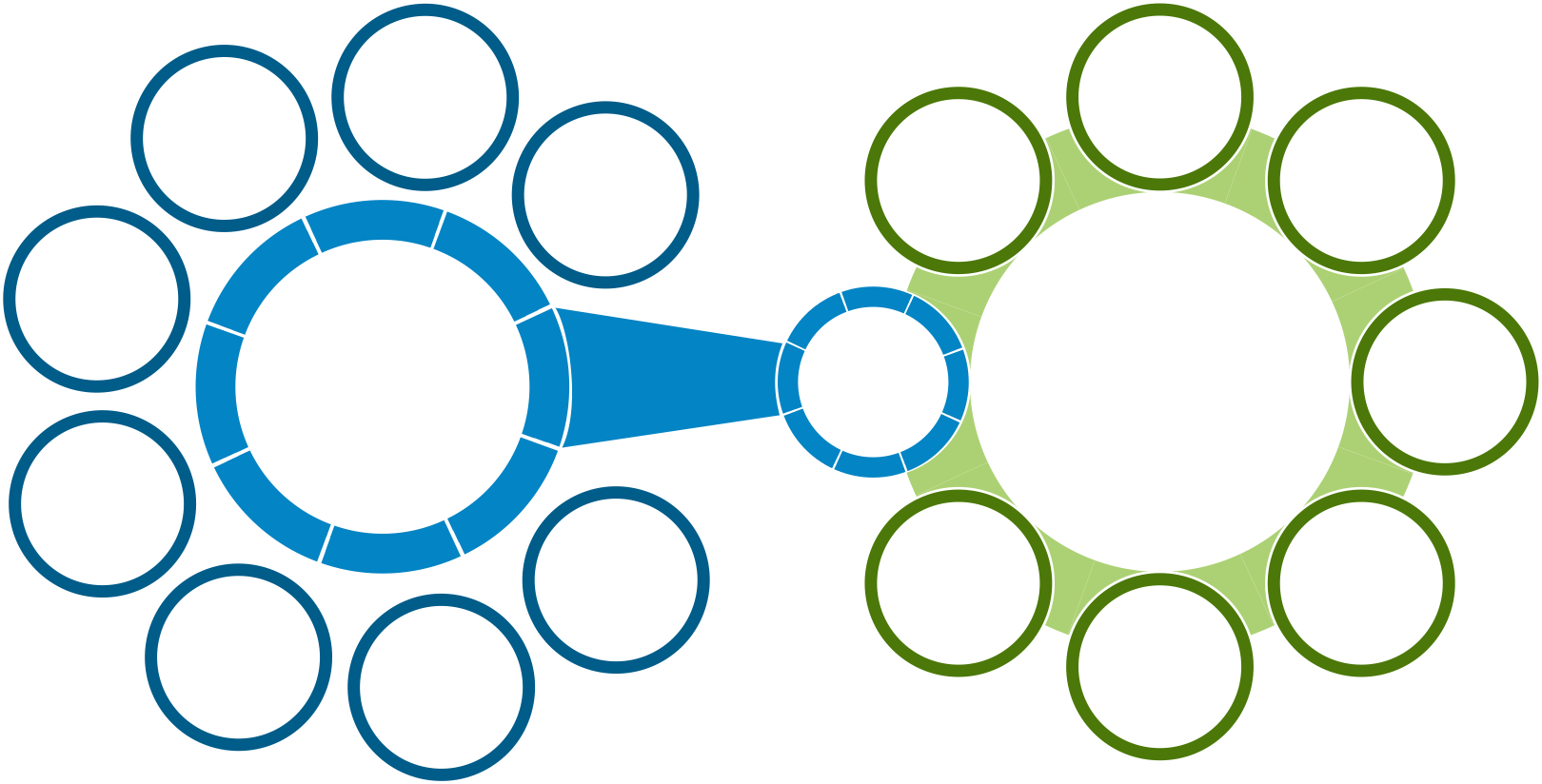

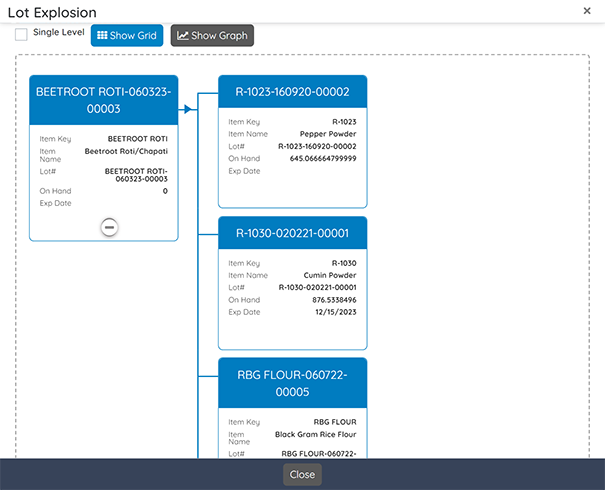

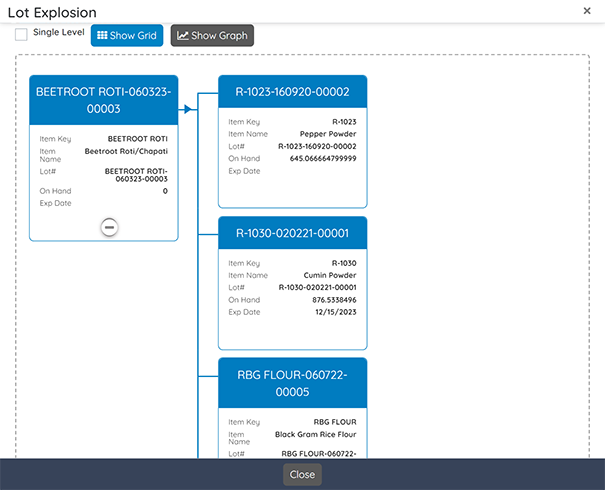

Traceability

Key features include:

- Automatic Lot Numbering: Assign lot numbers automatically during receiving and production.

- Lifecycle Tracking: Capture and validate lot numbers at every stage of production.

- Quick Searches: Perform bi-directional searches using an intuitive graphical tool.

- Recall Management: Generate barcoded labels (e.g., product labels, pallet licenses) to further streamline operations.

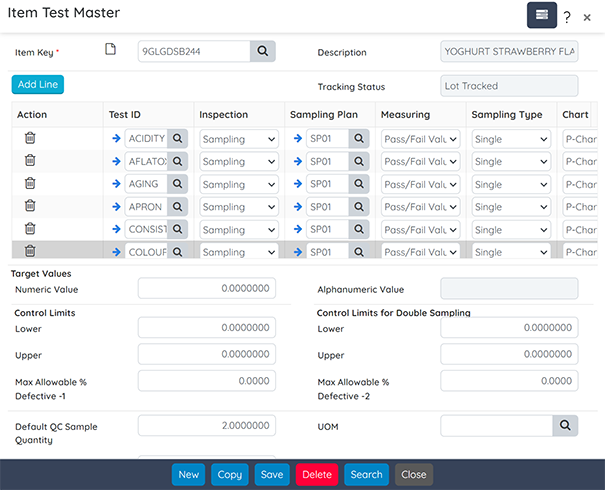

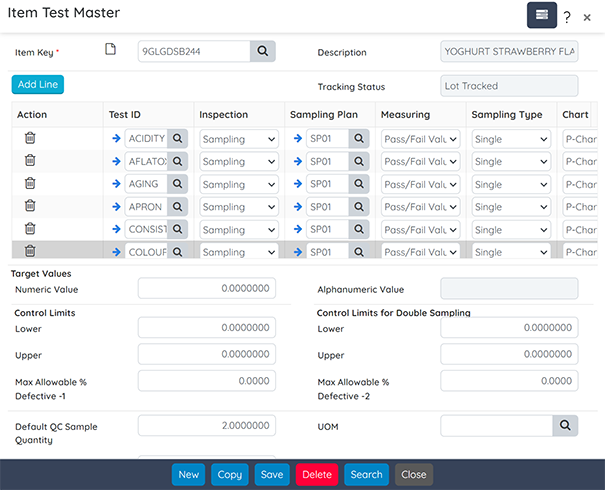

Quality

Integrate quality control and assurance throughout all processes, ensuring product safety and compliance.

Key features include:

- QC Testing: Set up quality control tests with specified tolerance and sample values.

- Inspection Plans: Execute comprehensive inspection plans and checklists.

- Documentation: Generate Certificates of Analysis (COA) and manage production deviations.

- Issue Management: Address customer complaints and nonconformance situations effectively.

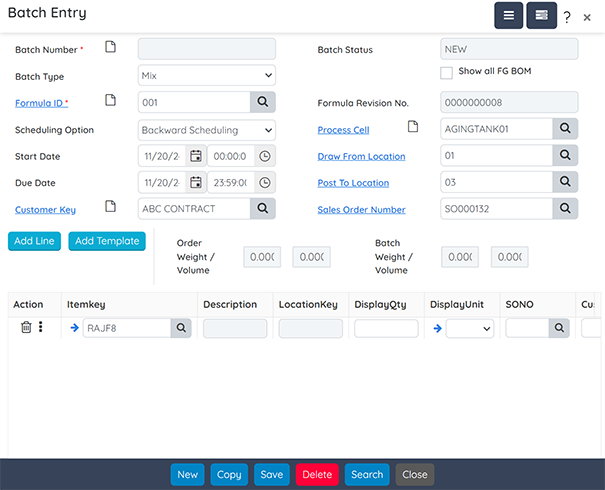

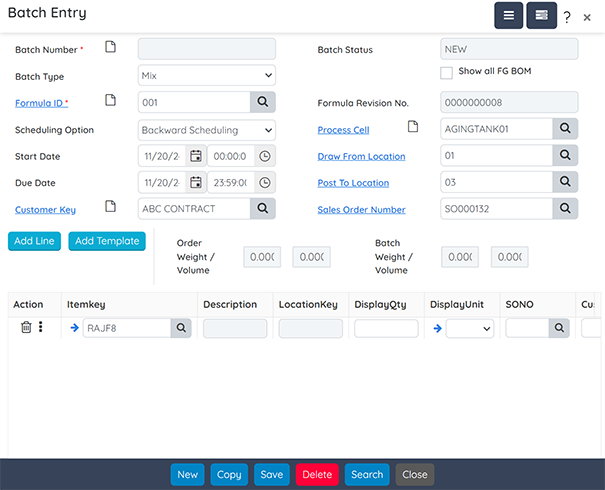

Production

Optimize production processes for intermediates and finished goods, including co-products and by-products.

Key capabilities include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

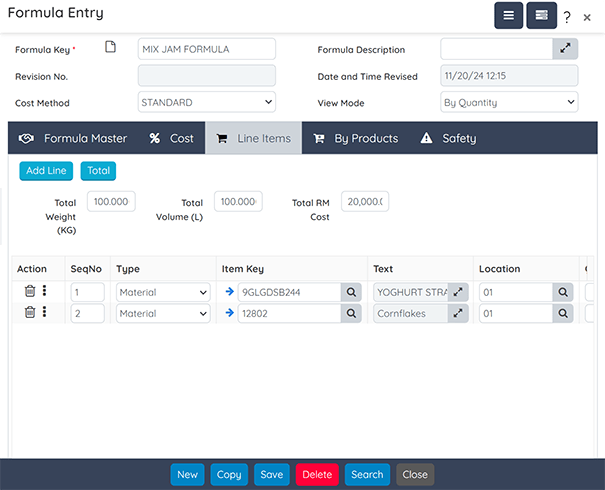

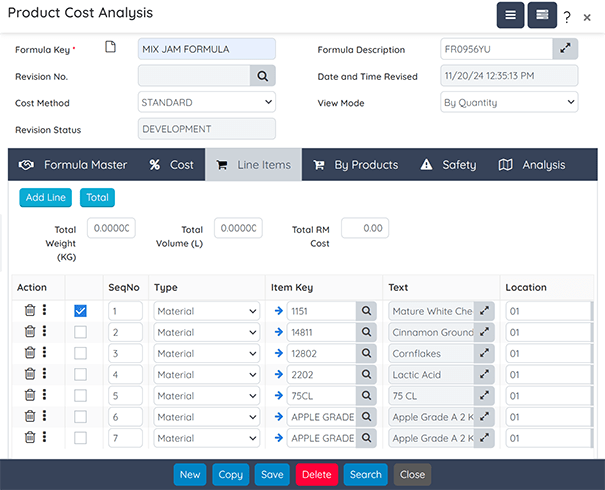

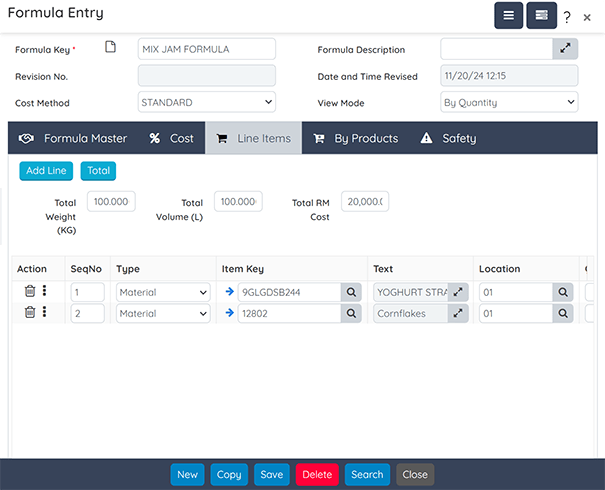

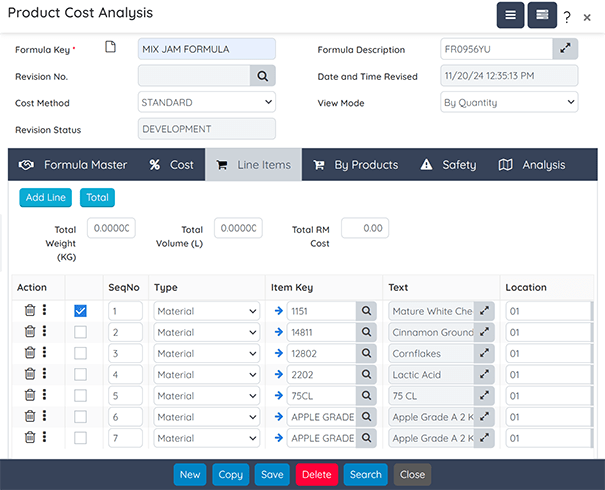

Formulation

Facilitate the management of product specifications across multiple versions and formulations.

Key features include:

- Dynamic Adjustments: Modify ingredient weights and volumes to achieve target properties.

- Cost Analysis: Account for fixed and variable labor and consumable costs.

- Specification Comparison: Analyze and compare different product specifications.

- Workflow Approval: Employ multi-level workflows for formulation approvals.

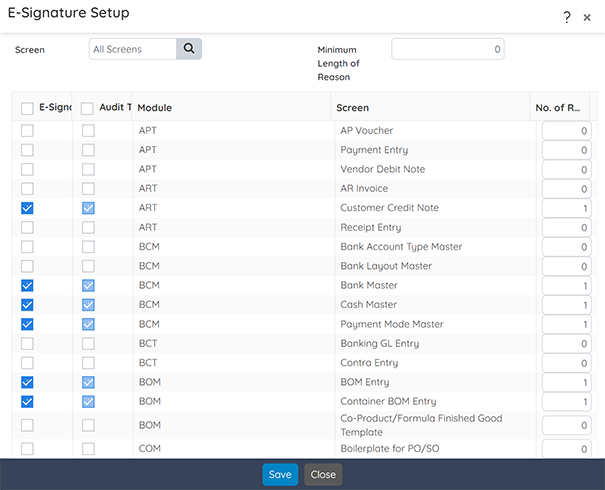

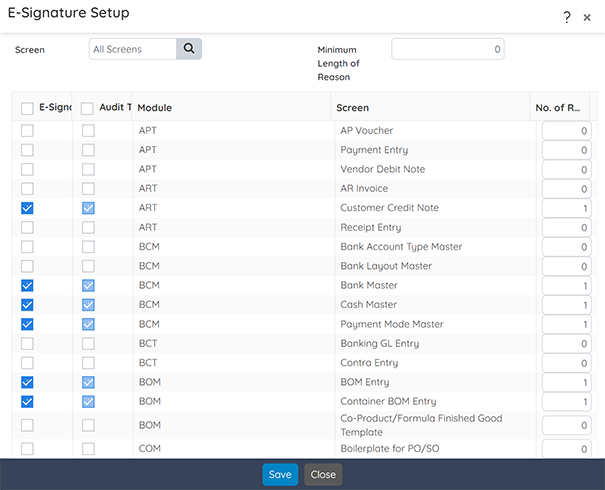

Compliance

Ensure adherence to federal and industry-specific regulations throughout every process.

Key functionalities include:

- Real-Time Alerts: Notify formulators when specifications exceed established levels.

- Data Capture: Mandate the collection of item, user, and location data for compliance (CFR 11).

- Audit Trail Maintenance: Maintain transactional history for auditor reporting, including Master Batch Records.

- Label Generation: Automatically generate required product and safety labels and documents.

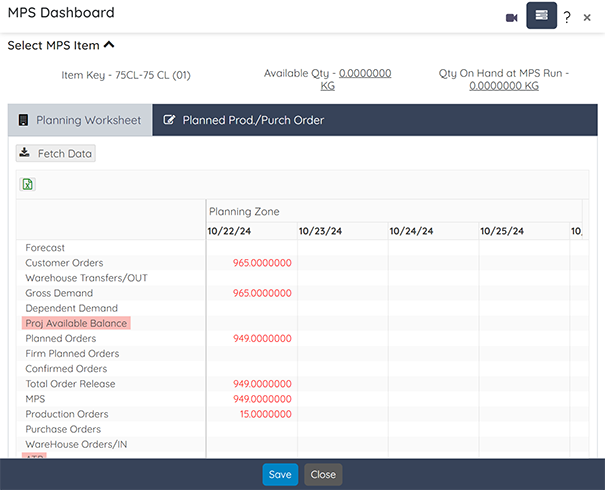

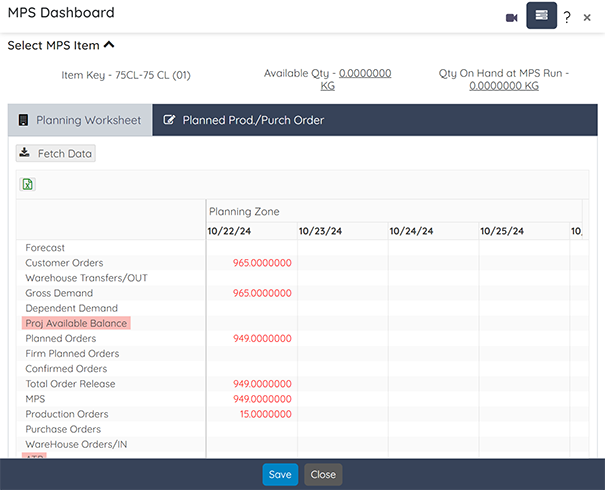

Planning & Scheduling

Optimize production and procurement processes to meet demand effectively.

Key capabilities include:

- Comprehensive Planning: Establish short, medium, and long-range planning periods.

- Facility Management: Plan production by facility or across multiple locations.

- Supply and Demand Consolidation: Streamline supply and demand management across facilities.

- What-If Analysis: Perform scenario analysis while planning production schedules.

Mobile Warehousing

Key capabilities include:

- Batch Job QC Test: Capture QC information for inbound raw materials and WIP.

- Equipment Checklists and Inspections: Check the physical condition of on-hand inventory.

- Validate inventory location, license ID, lot number, and quantity.

- Generate required labels and reports: Generate barcoded labels (e.g. product labels and pallet licenses) to further streamline operations.

Cost Analysis

Balance consumer preferences with cost-effectiveness and production efficiency.

Key capabilities include:

- Comprehensive cost analysis of specifications

- Comparing costs associated with ingredients, labor, consumables, and additional shipping or miscellaneous expenses

Inventory

Key features include:

- Automatic Lot Numbering: Assign lot numbers automatically during receiving and production.

- Lifecycle Tracking: Capture and validate lot numbers at every stage of production.

- Quick Searches: Perform bi-directional searches using an intuitive graphical tool.

- Recall Management: Generate barcoded labels (e.g., product labels, pallet licenses) to further streamline operations.

Quality

Key features include:

- QC Testing: Set up quality control tests with specified tolerance and sample values.

- Inspection Plans: Execute comprehensive inspection plans and checklists.

- Documentation: Generate Certificates of Analysis (COA) and manage production deviations.

- Issue Management: Address customer complaints and nonconformance situations effectively.

Production

Key capabilities include:

- Dynamic Job Scheduling: Link and schedule dependent batch jobs based on resource availability.

- Resource Management: Manage equipment capacities and resource allocations efficiently.

- Deviation Capture: Record and address deviations during production runs.

- Inventory Backflushing: Automatically backflush inventory for completed jobs.

Formulation

Key features include:

- Dynamic Adjustments: Modify ingredient weights and volumes to achieve target properties.

- Cost Analysis: Account for fixed and variable labor and consumable costs.

- Specification Comparison: Analyze and compare different product specifications.

- Workflow Approval: Employ multi-level workflows for formulation approvals.

Compliance

Key functionalities include:

- Real-Time Alerts: Notify formulators when specifications exceed established levels.

- Data Capture: Mandate the collection of item, user, and location data for compliance (CFR 11).

- Audit Trail Maintenance: Maintain transactional history for auditor reporting, including Master Batch Records.

- Label Generation: Automatically generate required product and safety labels and documents.

Planning & Scheduling

Optimize production and procurement processes to meet demand effectively.

Key capabilities include:

- Comprehensive Planning: Establish short, medium, and long-range planning periods.

- Facility Management: Plan production by facility or across multiple locations.

- Supply and Demand Consolidation: Streamline supply and demand management across facilities.

- What-If Analysis: Perform scenario analysis while planning production schedules.

Mobile Warehousing

Key capabilities include:

- Batch Job QC Test: Capture QC information for inbound raw materials and WIP.

- Equipment Checklists and Inspections: Check the physical condition of on-hand inventory.

- Validate inventory location, license ID, lot number, and quantity.

- Generate required labels and reports: Generate barcoded labels (e.g. product labels and pallet licenses) to further streamline operations.

Cost Analysis

Key capabilities include:

- Comprehensive cost analysis of specifications

- Comparing costs associated with ingredients, labor, consumables, and additional shipping or miscellaneous expenses

See What Other Process Manufacturers Are Saying

Metarom

We had a great experience with the BatchMaster implementation, and the support team. Everyone was very knowledgeable, and committed to helping us implement the system as fast as possible

Westwood Laboratories

The potential within BatchMaster is limitless and we are confident that BatchMaster will allow us to adapt to new FDA requirements in the future

Polytex Environmental Inks, ltd.

We may need to replace the components with every sale, but the base remains constant. It’s the finished formula that changes by request. BatchMaster understood those requirements. BMM seems to think the same ways as we do.

Metarom

We had a great experience with the BatchMaster implementation, and the support team. Everyone was very knowledgeable, and committed to helping us implement the system as fast as possible

Westwood Laboratories

The potential within BatchMaster is limitless and we are confident that BatchMaster will allow us to adapt to new FDA requirements in the future

Polytex Environmental Inks, ltd.

We may need to replace the components with every sale, but the base remains constant. It’s the finished formula that changes by request. BatchMaster understood those requirements. BMM seems to think the same ways as we do.

Upgrade to BatchMaster for Your Industry-Specific Manufacturing Requirements

Frequently Asked Questions

What challenges does BatchMaster help solve for the process manufacturing industry?

BatchMaster addresses key challenges in manufacturing, including:

- Formulation Costs: Compare ingredient, labor, and shipping costs for informed decision-making.

- Fluctuating Prices: Get accurate cost estimates that account for commodity price fluctuations.

- Shelf Life Management: Optimize inventory use with expiration date tracking and rotation methods.

- Product Consistency: Manage ingredient variations to maintain quality and consistency.

- Supply Chain Disruptions: Adjust batch jobs based on raw material availability.

- Seasonal Demand: Automate batch job and purchase order forecasting based on seasonal demand.

- Regulatory Compliance: Ensure compliance with safety standards and labeling requirements through built-in tools.

What are the key features of BatchMaster ERP?

Key features include recipe and packaging management, costing & analysis, batch production, planning, inventory control, quality assurance, lot traceability, compliance tracking, and reporting and analytics—all tailored for specific industries.

Can BatchMaster integrate with my existing systems?

Yes, BatchMaster is designed to integrate seamlessly with applications, such as SAP Business One, QuickBooks, Sage 100 & 300, Microsoft Dynamics GP, Microsoft Dynamics 365 Business Central and others. This ensures a smooth flow of data across all your business operations.

How does BatchMaster ERP enhance operational efficiency?

By centralizing operations and automating processes, BatchMaster ERP reduces manual errors, improves data accuracy, and streamlines workflows, ultimately leading to greater operational efficiency and productivity.

What kind of support and training do you offer?

We provide comprehensive support and training for our customers. This includes onboarding assistance, user training, and ongoing technical support to ensure you maximize the benefits of using our solution.

About BatchMaster

Specialized in Process Manufacturing ERP

Industry leader for over 3 decades

3,000+ customers

Services Offered – Process consulting, Integration, Support, Training, GMP/FDA validation